One-step forming vacuum glass and its manufacturing method and device

A vacuum glass and manufacturing method technology, applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems of large air extraction resistance of air extraction holes, low product yield, and difficulty in vacuuming, etc., to achieve low resistance and simplify the process The effect of high flow and pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

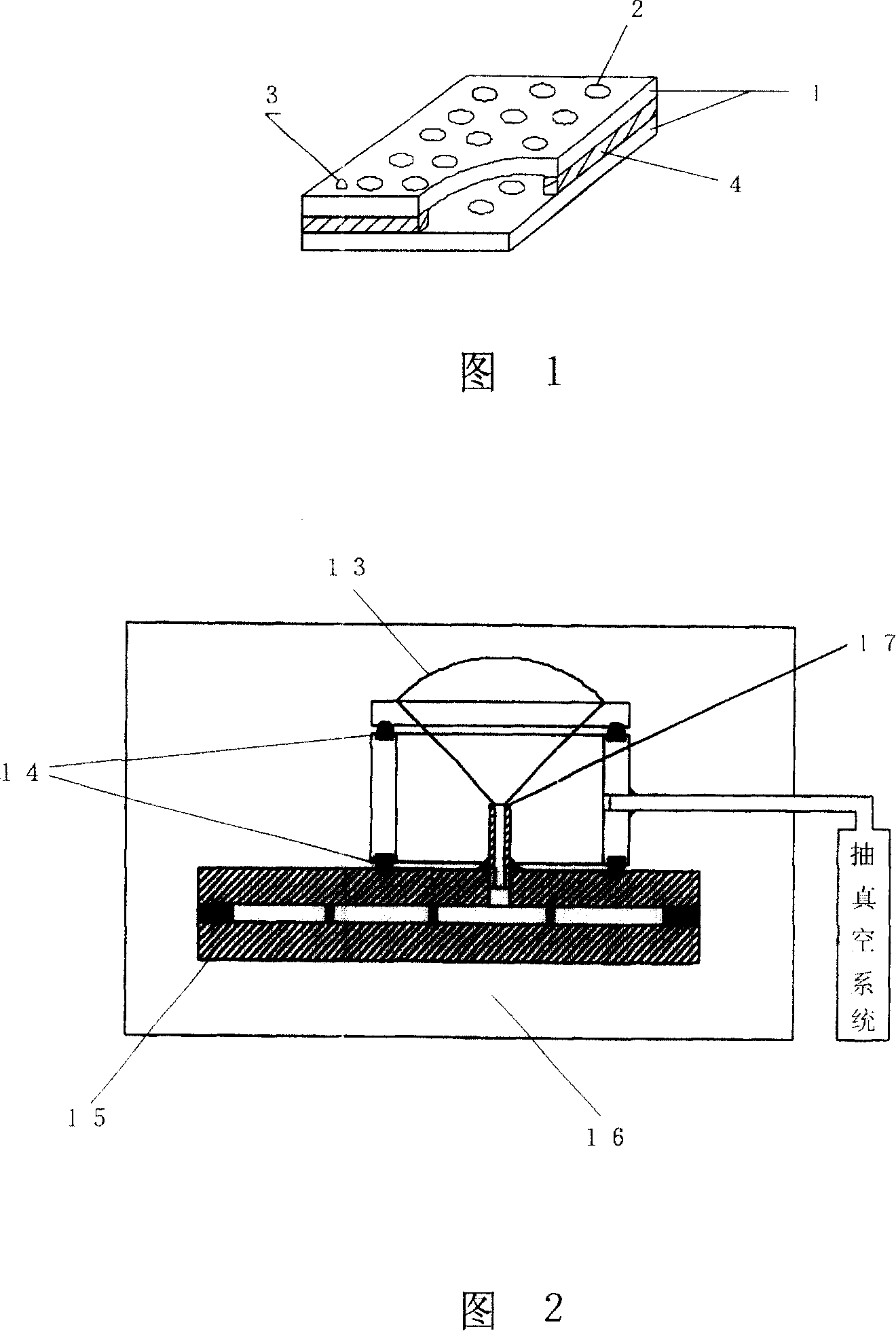

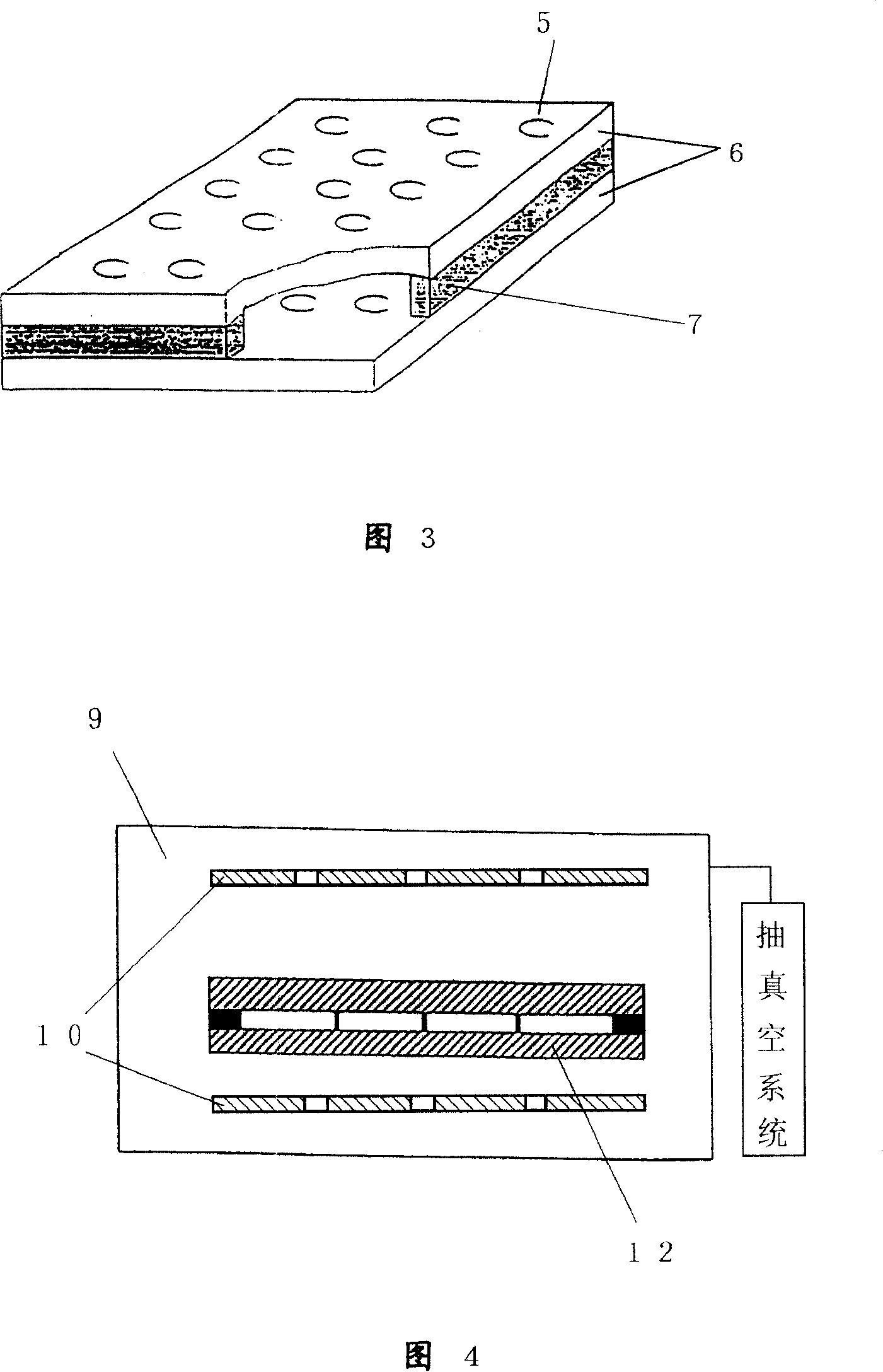

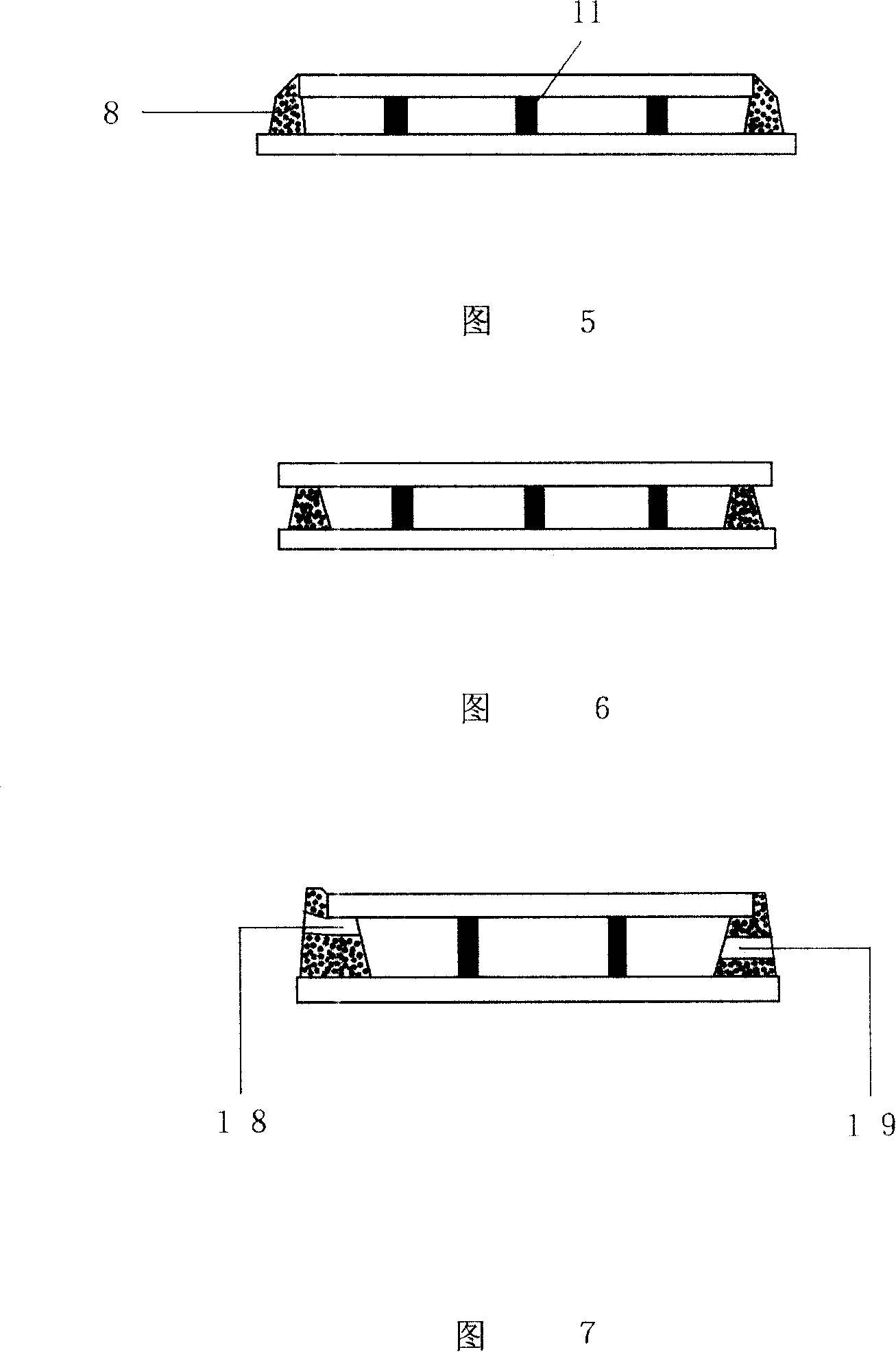

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings. The vacuum glass of the present invention is shown in Figure 3. The vacuum glass consists of an upper and lower glass plate 6, a support body 5 sandwiched between the upper and lower glass plates, and two glass plates. The sealing body 7 constitutes. Compared with the existing vacuum glass (as shown in Figure 1 ) sealed with welding glass powder, the existing vacuum glass has air vents 3, and the vacuum glass manufactured by the present invention does not have air vents, and other parts are the same.

[0043] As shown in Figure 4, place the vacuum glass original plate with welding glass powder and support in the sealable heating chamber 9, the vacuum system and the sealable heating chamber are connected through pipelines, and there is a heating device in the sealable heating chamber 9 10. The heating device 10 is the heating part of the heating device, which uses resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com