Pad material, method of sewing pad material and apparatus of sewing pad material

A mat and sewing thread technology, applied in special positions of vehicles, sewing equipment, transportation and packaging, etc., can solve problems such as damage to the sense of unity, user incongruity, damage to the appearance of cushion materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

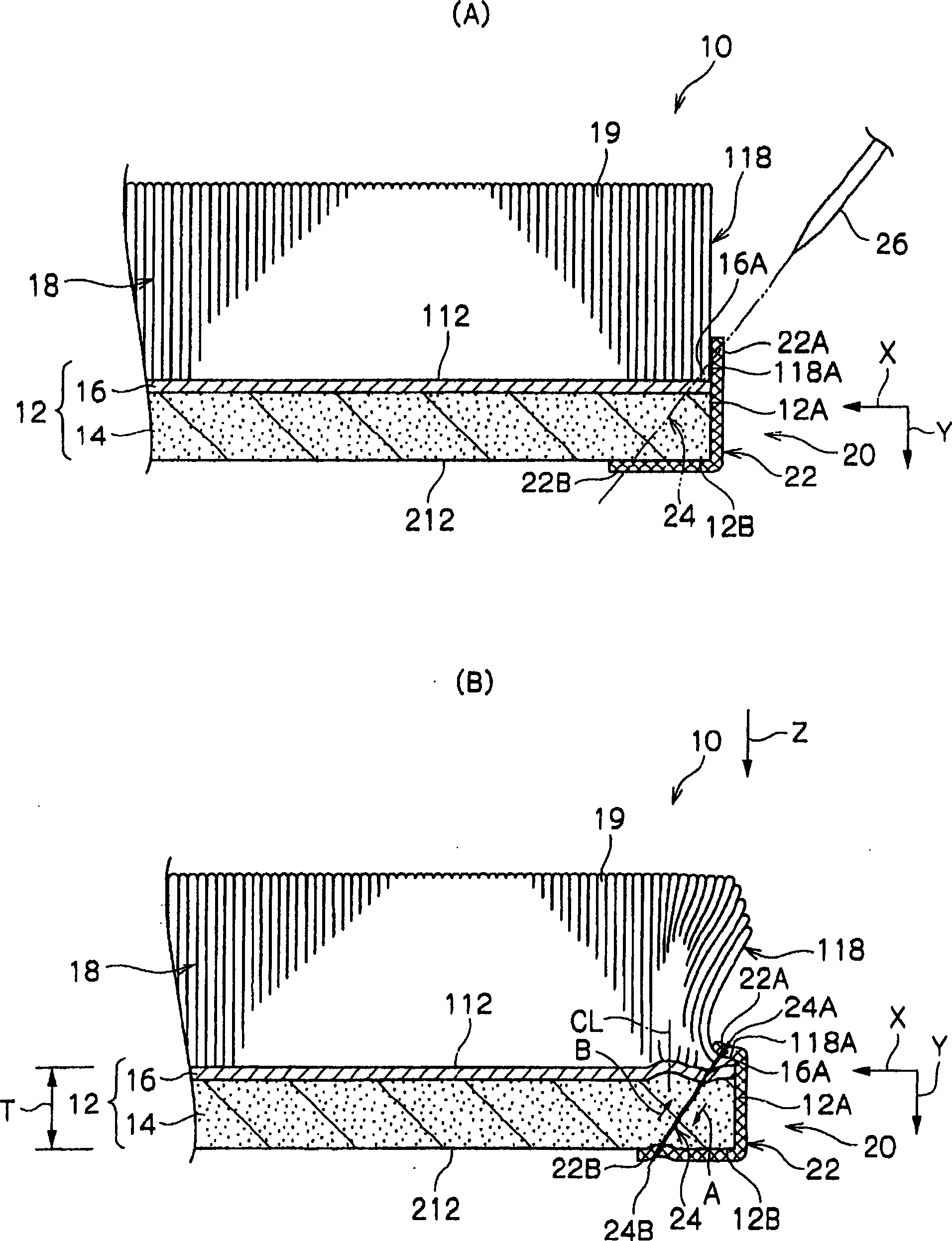

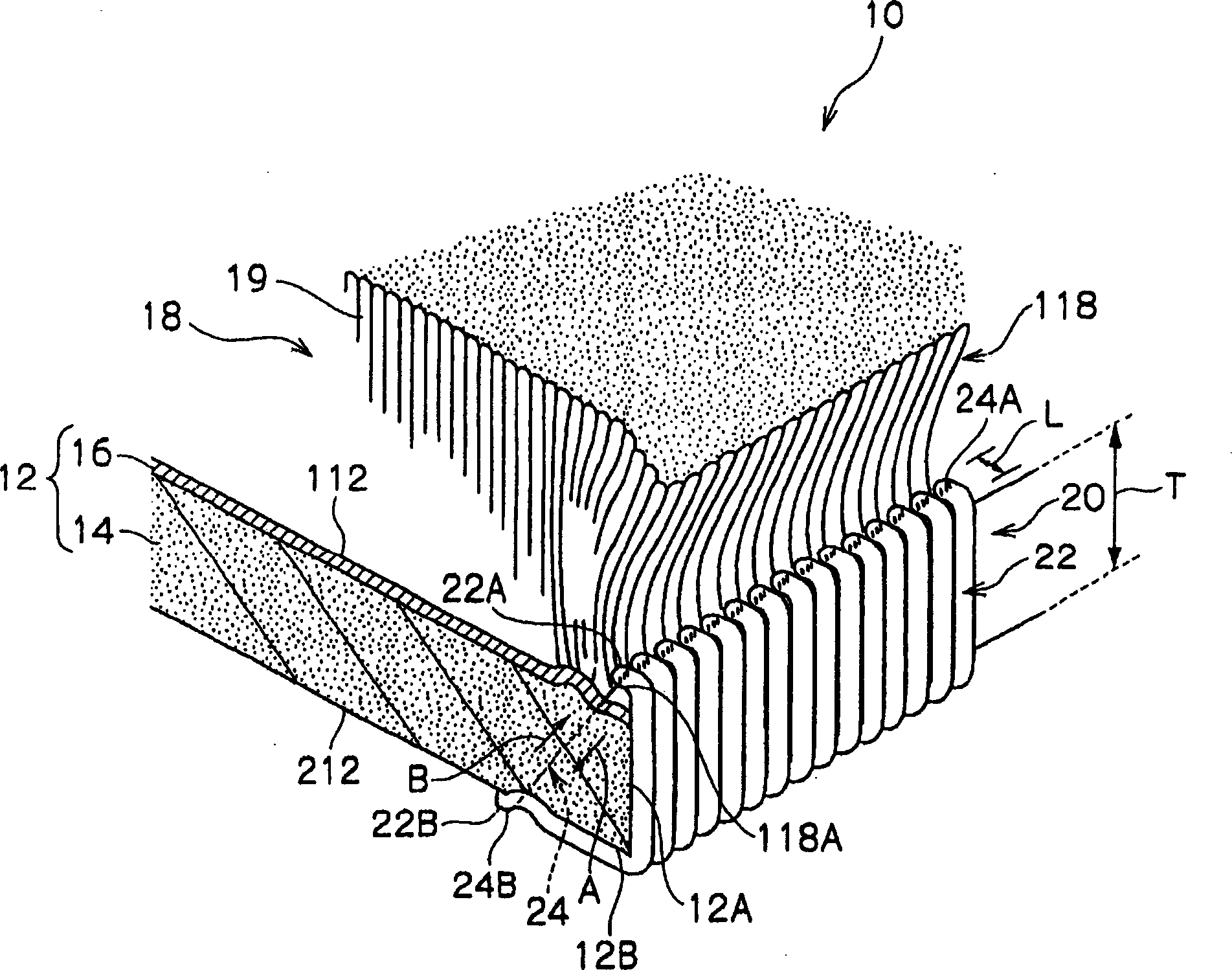

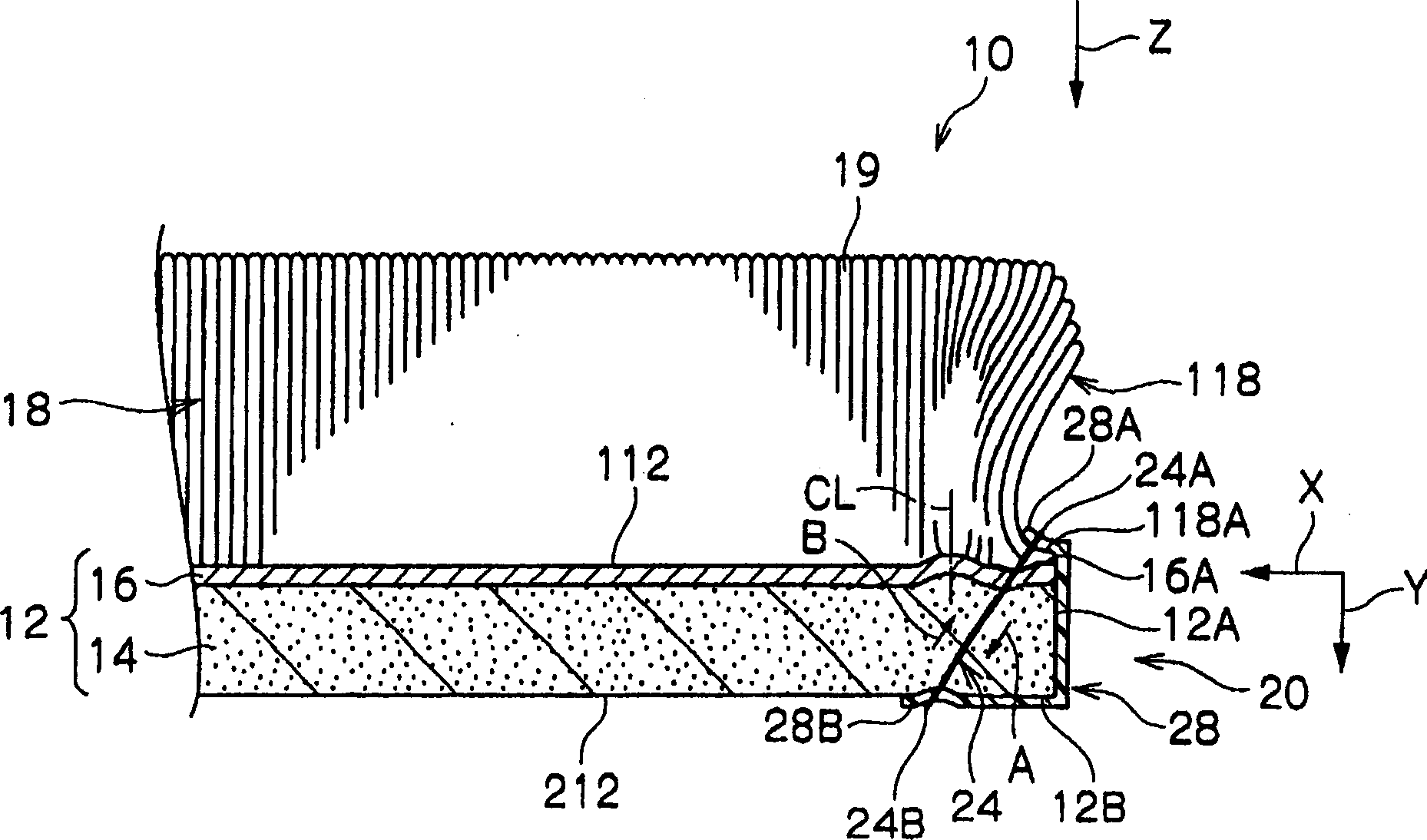

[0036] A first embodiment of the mat material in the present invention will be described with reference to the drawings. The mat material in the present embodiment is a floor mat as an interior material laid in the cabin of an automobile.

[0037] Such as figure 1 As shown in (A), the floor mat 10 has the mat base material 12 having the back surface 212 as a laying surface. The mat base material 12 has a laminated structure, and has a base fabric 14 made of felt in the lower layer, and the cushioning performance is obtained by the base fabric 14 . The backing layer 16 is provided on the base fabric 14 so as to cover the base fabric 14 .

[0038] Above the backing layer 16, a skin layer 18 supported by the backing layer 16 is formed. The base end of the skin layer 18 is implanted into the backing layer 16, and the above-mentioned skin layer 18 is made of many fibrous fluffs 19 erected parallel to each other, and is laid on the surface 112 (the opposite side of the back surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com