Heat preservation pit or burial pit as well as pouring material and process of working layer thereof

A technology of pouring materials and slow cooling pits, applied in the field of refractory materials, can solve the problems of costing maintenance funds, inconvenient structure and lining materials, etc., and achieve the effect of saving maintenance funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

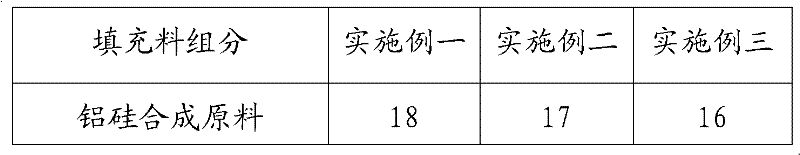

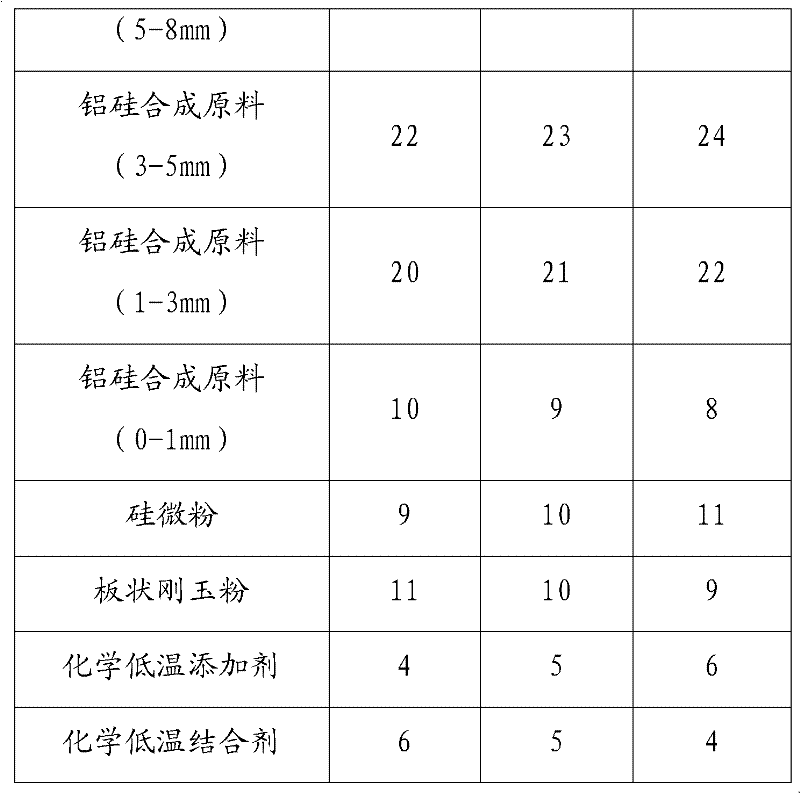

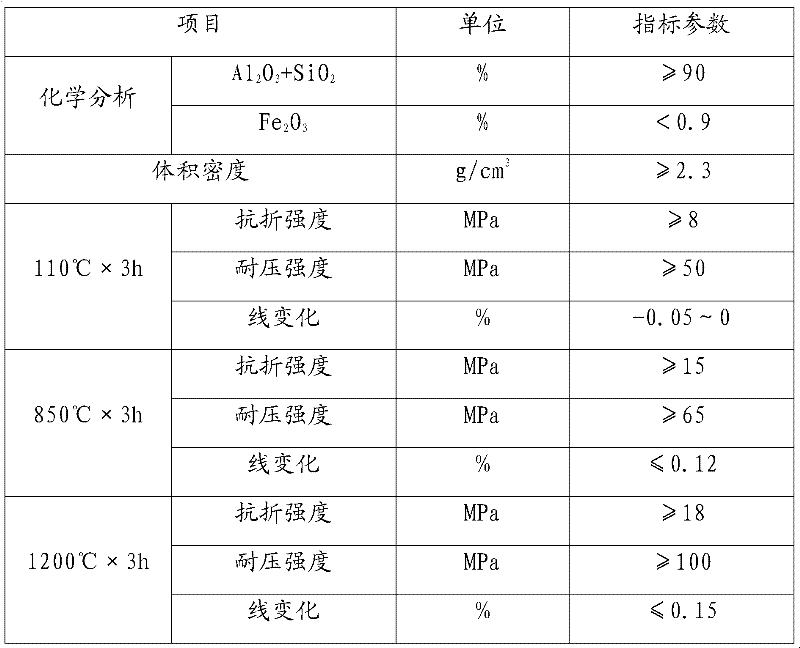

[0014] The pouring material for the working layer of the heat preservation pit or slow cooling pit of the present invention is formed by uniformly mixing aluminum-silicon synthetic raw materials, including silicon micropowder, platy corundum powder, chemical low-temperature additives, and chemical low-temperature binder micropowder. The mass percentages are listed in Table 1.

[0015] Table I

[0016] material name

Particle size composition (mm)

Percentage (%)

Aluminum silicon synthesis raw material

8-5

16-18

Aluminum silicon synthesis raw material

5-3

22-24

Aluminum silicon synthesis raw material

3-1

20-22

Aluminum silicon synthesis raw material

1-0

8-10

Silica powder

500 mesh

8-12

Tabular alumina powder

320 mesh

8-12

Chemical Low Temperature Additives

Micropowder

4-6

chemical low temperature binder

Micropowder

4-6

[0017...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com