Simplified method for making an impermeable joining on three-layer or bi-layer fabric materials

A technology of fabric materials and double-layer fabrics, which is applied to the seams of textile materials, fabric trimming, fabric surface trimming, etc., can solve the problems of difficult execution, many steps, and cumbersome processes, and achieve good anti-permeability performance and step-by-step The effect of less and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

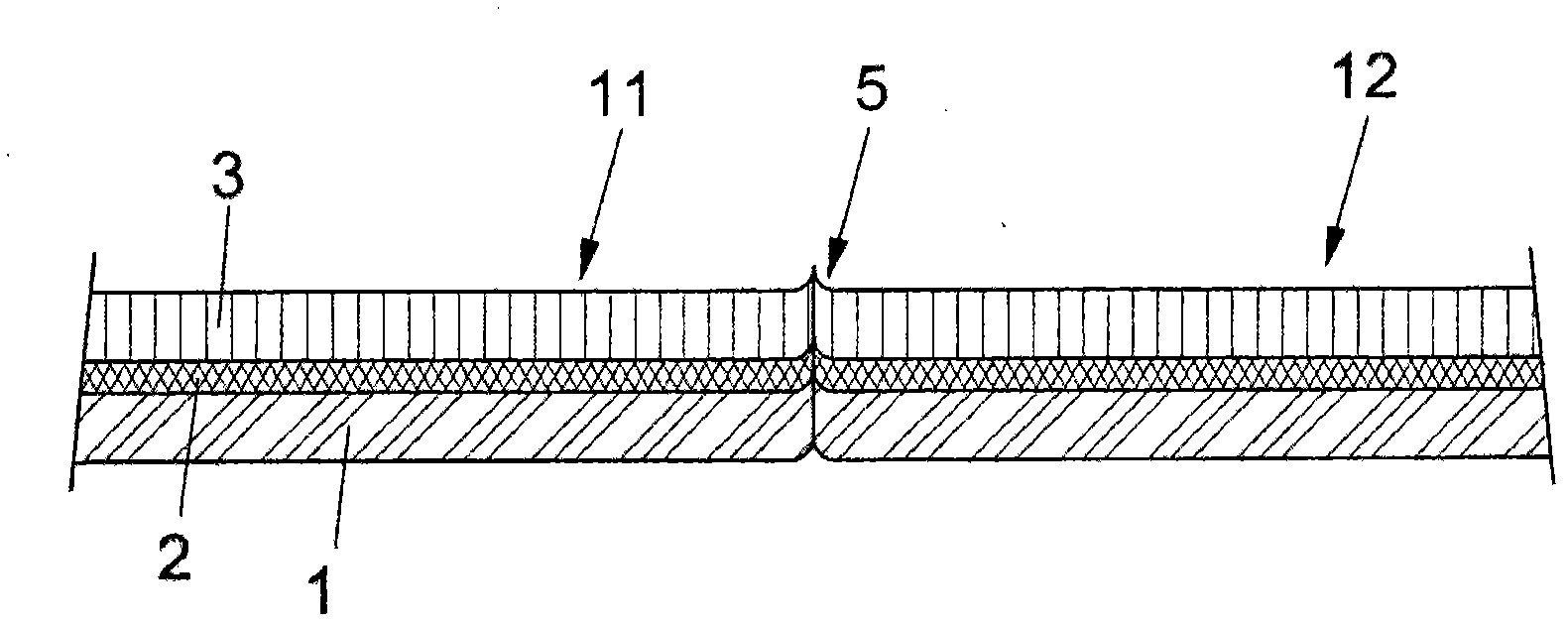

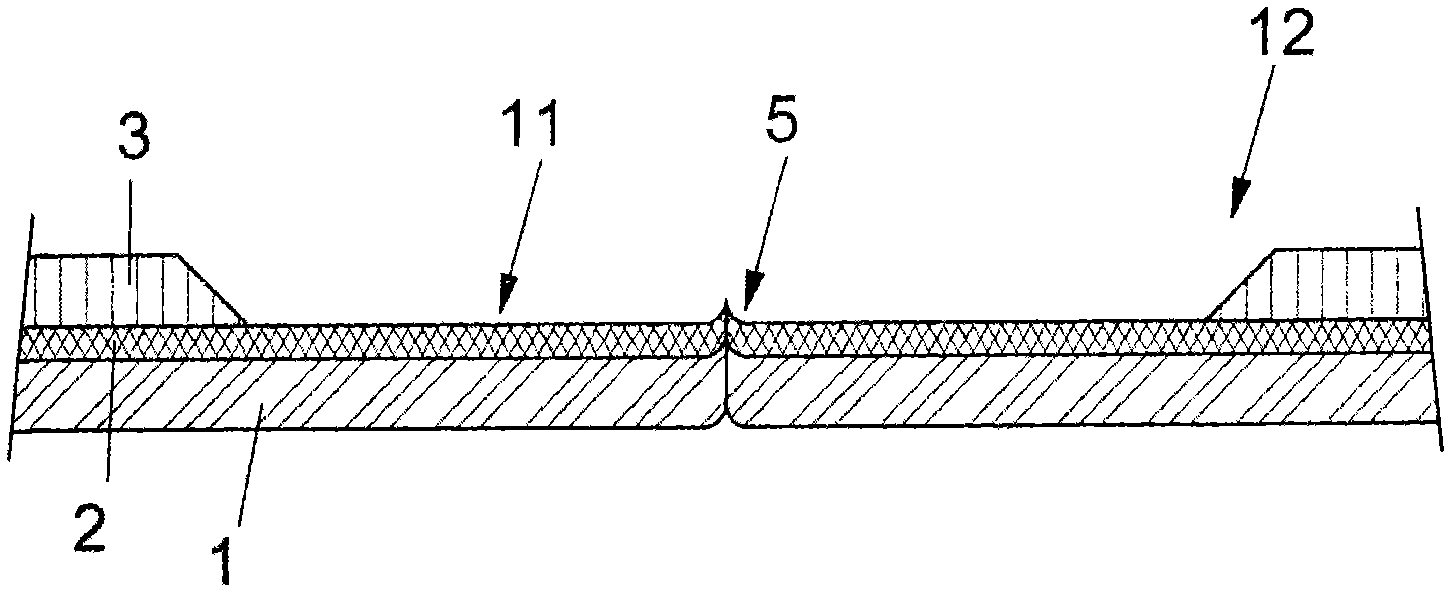

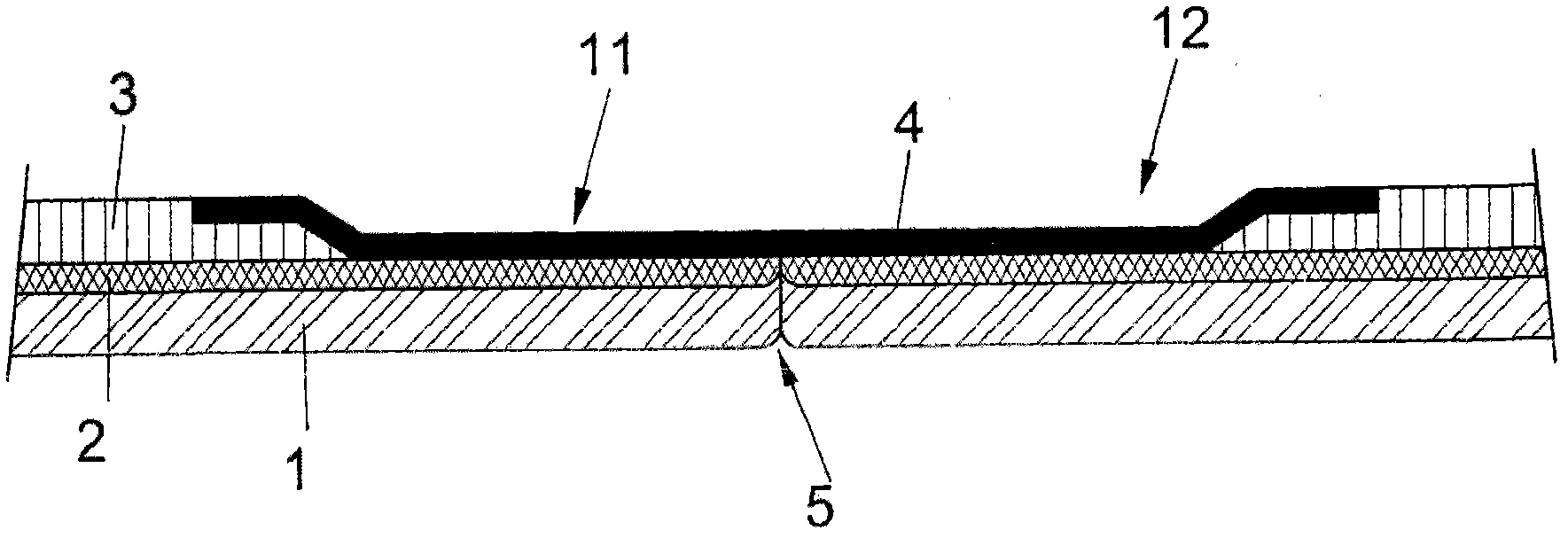

[0042] With reference to the reference numerals of the above-mentioned figures, a simplified method for forming a permeation-proof joint on a three-layer or two-layer fabric material, wherein a joint side of the fabric material has a composite structure or does not have a composite structure, and the The fabric material is joined beforehand by a suture joining operation or an ultrasonic joining operation, this simplified method comprises only two operating steps, a first operating step being: by means of a suture joining or an ultrasonic joining operation will be denoted by reference numerals 11 and 12 two fabric or textile trims or two fabric or textile segments; and a second impermeable joining operation comprising: an ironing joining step performed by a single device in a single process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com