Total polyester superfine denier fabric and its processing method

A processing method and ultra-fine denier technology, applied in the field of polyester fiber products, can solve problems such as uneven color yield, influence of grammage, large difference in color depth on the back, etc., achieve uniform particle size, isolate internal and external air, and concise process steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

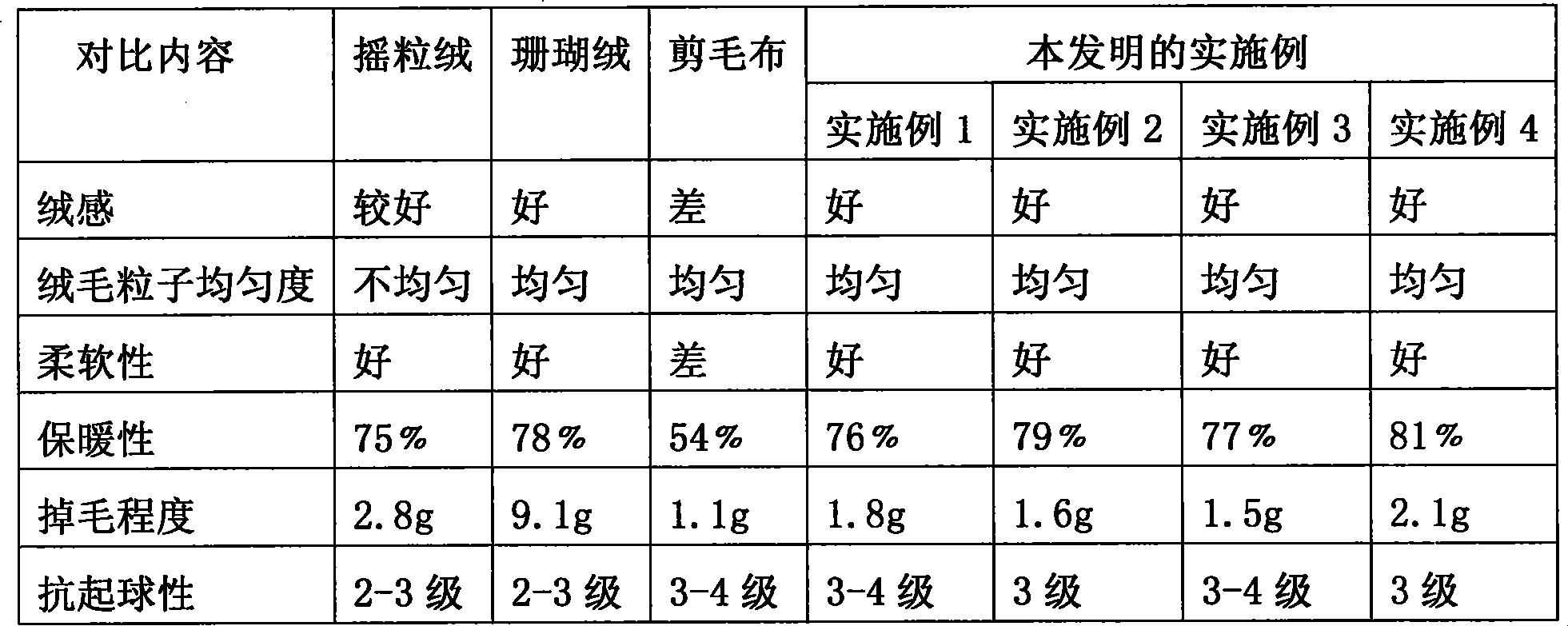

Examples

Embodiment 1

[0028] The processing width is 156cm and the weight is 160g / m 2 And take the one-side sheared and dyed all-polyester ultra-fine denier fabric as terry cloth as an example, the steps are as follows:

[0029] A) Raw material preparation, choose 100D / 144F polyester DTY silk as face silk, choose 100D / 36F polyester DTY silk as bottom silk, wherein 100D / 144F accounts for 65%, 100D / 36F accounts for 35%, described percentage is mass percentage, Weaved by the PK single-jersey machine produced and sold by Li Kemao Company in Taiwan, China, the weight is 190g / m 2 , white gray cloth with a door width of 200cm;

[0030] B) sectioning, the white gray cloth obtained by step A) is sent to the cutting machine to cut the width, so as to obtain the white gray cloth;

[0031] C) shearing, sending the white gray cloth of cut width obtained by step B) to a shearing machine for shearing, and the hair height is 3mm, and obtains the gray gray cloth of shearing;

[0032] D) heat setting, the sheared...

Embodiment 2

[0037] Polyester ultra-fine denier terry cloth printing (single side), finished product width 150cm, weight 195g / m 2 , the steps are as follows:

[0038] A) Raw material preparation, choose 150D / 288F polyester DTY silk as the face thread, choose 100D / 36F polyester DTY silk as the bottom thread, wherein 150D / 288F accounts for 70%, 100D / 36F accounts for 30%, and the stated percentages are mass percentages, Weaved by the PK single-jersey machine produced and sold by Li Keluo Company in Taiwan, China, the weight is 235g / m 2 , white gray cloth with a door width of 195cm;

[0039] B) sectioning, the white gray cloth obtained by step A) is sent to the cutting machine to cut the width, so as to obtain the white gray cloth;

[0040] C) shearing, sending the white gray cloth obtained by step B) to a shearing machine for shearing, and the hair height is 3.5mm to obtain a sheared gray cloth;

[0041] D) heat setting, the sheared gray cloth obtained by step C is sent to a setting machin...

Embodiment 3

[0046] Polyester ultra-fine denier terry dyeing (double-sided), finished product width 146cm, weight 160g / m 2 , the steps are as follows:

[0047] A) Raw material preparation, choose 150D / 288F DTY polyester yarn as the face yarn, choose 100D / 36FDTY polyester yarn as the bottom yarn, wherein 150D / 288F accounts for 60%, 100D / 36F accounts for 40%, and the percentages mentioned are mass percentages. The PK single-sided machine weaving produced and sold by Taiwan Li Kexiang Company has a grammage of 190g / m 2 , white gray cloth with a door width of 190cm;

[0048] B) sectioning, the white gray cloth obtained by step A) is sent to the cutting machine to cut the width, so as to obtain the white gray cloth;

[0049] C) shearing, will be sent to the shearing machine by step B) obtained cut white gray cloth, and the wool height is 4mm, obtains the sheared gray cloth;

[0050] D) heat setting, the sheared gray cloth obtained by step C) is sent to a setting machine for heat setting, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com