Halogen-free epoxy adhesive and cover film prepared by using halogen-free epoxy adhesive

An epoxy adhesive and adhesive technology, applied in the directions of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of reduced heat resistance, increased water absorption, uneven dispersion of fillers affecting the performance of the cover film, etc. Excellent heat resistance, the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

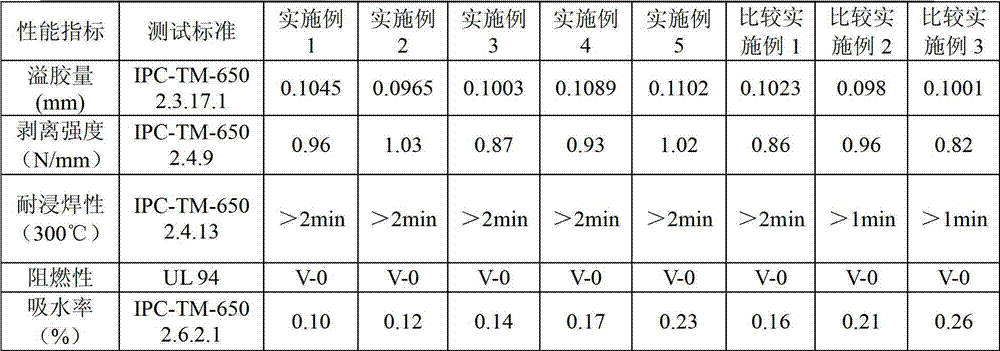

Examples

Embodiment 1

[0024] Take 15 parts by weight of phosphorus-containing epoxy resin FX-305 (TOHTO Chemical Industry Co., Ltd. epoxy equivalent 500g / eq), rubber body modified epoxy resin Epon Resin 58005 (Hexion Specialty Chemicals, Inc., rubber content 40wt %) 25 parts, toughening agent 1072CG (Zeon Corporation, acrylonitrile content 27wt%) 20 parts, 4,4'-diaminodiphenylsulfone 7.26 parts by weight; 1-cyanoethyl-2-ethyl-4-methyl 0.20 parts by weight of imidazole (2E4MZ-CN, Shikoku Chemicals); 15 parts by weight of aluminum hydroxide; 5 parts by weight of phosphorus-containing flame retardant OP-935 (Germany Clariant, phosphorus content 23%); nitrogen-containing flame retardant ( Melapur MC15) 5 parts by weight; 0.20 parts of antioxidant, adjust the solid content of the adhesive to 40wt% with butanone solvent, and mix it into a halogen-free epoxy adhesive.

[0025] The adhesive is coated on a polyimide film with a thickness of 12.5 μm by a coating machine, and then heated in an oven at 120° C....

Embodiment 2

[0028] Phosphorus-containing epoxy resin FX-305 (TOHTO Chemical Industry Co., Ltd. epoxy equivalent 500g / eq) 25 parts by weight; rubber modified epoxy resin Epon Resin 58005 (Hexion Specialty Chemicals, Inc., rubber content 40wt%) 20 parts; toughening agent 1072CG (Zeon Corporation, acrylonitrile content 27wt%) 20 parts; 4,4'-diaminodiphenylsulfone 7.93 parts by weight; 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN Shikoku Chemicals) 0.20 parts by weight; aluminum hydroxide 15 parts by weight; phosphorus-containing flame retardant OP-935 (Germany Clariant, phosphorus content 23%) 7 parts by weight; nitrogen-containing flame retardant (Melapur MC15) 5 parts by weight; 0.20 parts of antioxidant; use butanone solvent to adjust the solid content of the glue to 40wt%, and mix it into a halogen-free epoxy adhesive.

[0029] The adhesive is coated on a polyimide film with a thickness of 12.5 μm by a coating machine, and then heated in an oven at 120° C. for 4 minutes to form a sem...

Embodiment 3

[0032]Phosphorus-containing epoxy resin FX-305 (TOHTO Chemical Industry Co., Ltd. epoxy equivalent 500g / eq) 35 parts by weight; rubber modified epoxy resin Epon Resin 58005 (Hexion Specialty Chemicals, Inc., rubber content 40wt%) 20 parts; toughening agent 1072CG (Zeon Corporation, acrylonitrile content 27wt%) 25 parts; 4,4'-diaminodiphenylsulfone 8.45 parts by weight; 1-cyanoethyl-2-ethyl-4-methylimidazole (2E4MZ-CN Shikoku Chemicals) 0.20 parts by weight; aluminum hydroxide 20 parts by weight; phosphorus-containing flame retardant OP-935 (Germany Clariant, phosphorus content 23%) 5 parts by weight; nitrogen-containing flame retardant (Melapur MC15) 8 parts by weight; 0.20 parts of antioxidant; adjust the solid content of the glue solution to 40wt% with butanone solvent, and mix it into a halogen-free epoxy adhesive.

[0033] The adhesive is coated on a polyimide film with a thickness of 12.5 μm by a coating machine, and then heated in an oven at 120° C. for 4 minutes to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com