Oil/grease-and water sizing agent for treatment of cellulosic materials

A technology of sizing agent and cellulose, which is applied in the directions of adding water repellent, adding non-fiber pulp, and processing fiber raw materials to achieve high-efficiency performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0557] Examples: The numbers indicate the corresponding examples in the synthesis examples.

[0558] R F Equivalent: This column represents R in each monomer or polyamine unit F The molar mass of the group. This also indicates the number of J groups. R in each monomer unit F The molar amount of a group is also indicated by "r".

[0559] Epichlorohydrin Equivalent: This column represents the molar amount relative to the polyamine.

[0560] n: CH between amine nitrogen atoms 2 number of groups.

[0561] m: the number of repeating amine groups in structural formula I; the total number of amine groups is m+1.

[0562] R F Type: The type of the fluorinated group. In the preferred reaction mode, it is R on the fluoroepoxide F Substituents.

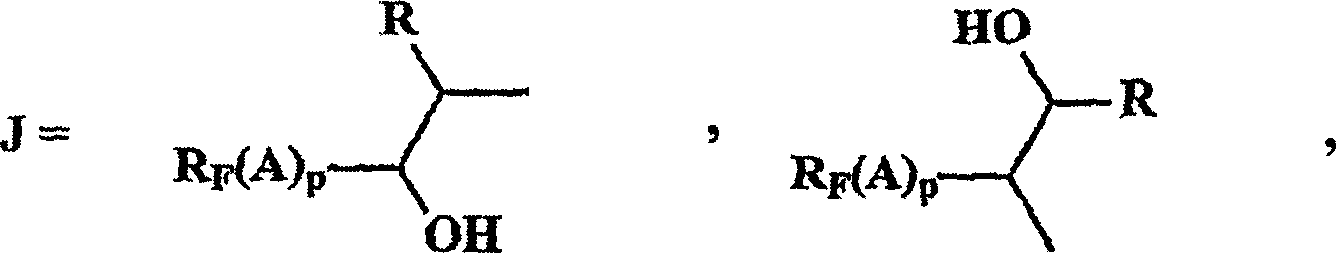

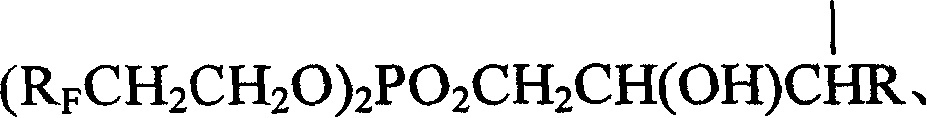

[0563] A: The group in formula III, J.

[0564] p: number of A groups in formula III, J.

[0565] r / N: The ratio of r groups to the total number of nitrogen atoms in the polyamine.

[0566] epi / N: Ratio of epichlorohydrin groups to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com