Novel fluorocarbon-graphene-acrylic polymer and preparation method thereof

A technology of acrylic acid and polymer, which is applied in the direction of plant fiber, anti-corrosion coating, textile and paper making, etc. It can solve the problems of insufficient waterproof and water pressure resistance, and achieve the effects of good transparency, excellent heat dissipation and wear resistance, and strong uniformity of coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

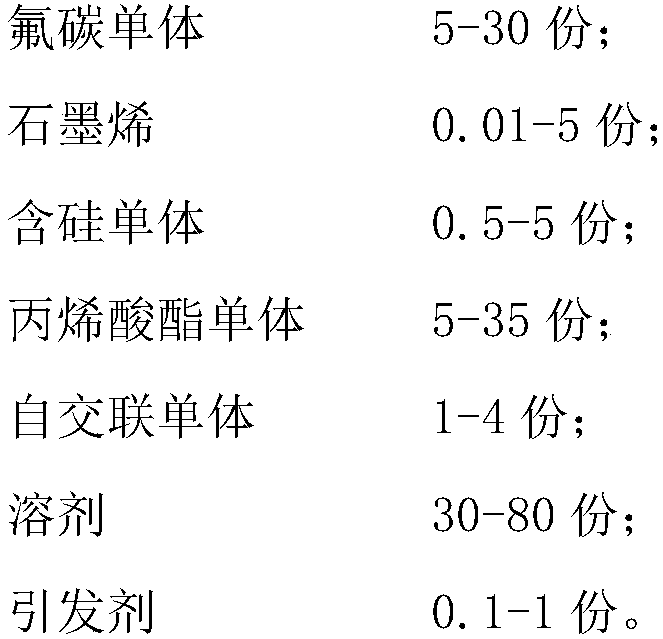

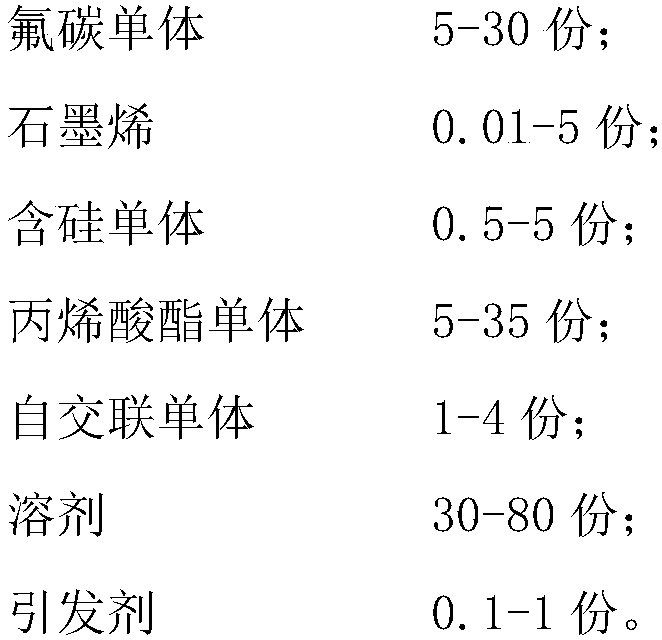

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of fluorocarbon graphene acrylic acid emulsion or solution

[0024] ①Preparation of fluorocarbon graphene acrylic acid emulsion: Take 15.00 g of monomer perfluoroalkyl ethyl acrylate, 3.808 g of y-(methacryloyloxy)propyltrimethoxysilane, 2 g of methyl methacrylate, and 10 g of acrylic acid Octalol ester 7g, fatty polyalcohol oxyethylene ether (3-15EO) 4g, emulsifier sodium lauryl sulfonate 1g, deionized water 60ml obtain stable pre-emulsion through high-pressure homogenizer emulsification in reaction vessel, Dissolve 0.700g of sodium persulfate in 20ml of deionized water, add 2 / 5 of the total volume of the pre-emulsion into a reactor equipped with a stirrer, thermometer, and condenser, stir and heat, raise the temperature to 40-80°C, add 2 / 5 of the total volume of the initiator, after half an hour of reaction, add the remaining pre-emulsifier and initiator dropwise, and continue the reaction for 5 hours after the addition is complete in 1 h...

Embodiment 2

[0031] Embodiment 2: the preparation of fluorocarbon graphene acrylic acid emulsion or solution

[0032]①Take 20.00g of monomer perfluoroalkyl octyl acrylate, 4g of y-(methacryloyloxy)propyltriethoxysilane, 308g of butyl acrylate, 9g of stearyl acrylate, 3g of methylol acrylamide, Emulsifier sodium dodecyl sulfonate 1g, fatty alcohol polyoxyethylene ether (OS-15) 3g, deionized water 24ml in the reaction vessel through high-pressure homogenizer emulsification to obtain a stable pre-emulsion, take sodium persulfate 0.690 Dissolve g in 8ml deionized water, add 2 / 5 of the pre-emulsion into a reactor equipped with a stirrer, a thermometer, and a condenser, stir and heat, raise the temperature to 40-80°C, add 2 / 5 of the initiator, and react for 1 hour Then add the remaining pre-emulsifier and initiator dropwise, continue the reaction for 4 hours after the dropwise addition is complete in 0.5 hours, cool down, add ammonia water to adjust the pH value to 6.0-8.0, and obtain a fluoroca...

Embodiment 3

[0037] Embodiment 3: the preparation of fluorocarbon graphene acrylic acid emulsion or solution

[0038] ①Take 25.00g of monomer perfluoroalkylnonyl acrylate, 6g of y-(methacryloyloxy)propyltriethoxysilane, 8g of acrylic acid, 6g of stearyl acrylate, 1.12g of methylol acrylamide, Branched-chain fatty alcohol polyoxyethylene ether (1312) 3g, emulsifier sodium dodecylsulfonate 1g, deionized water 50ml obtain stable pre-emulsion through high-pressure homogenizer emulsification in reaction vessel, take potassium persulfate 0.660 g was dissolved in 17ml of deionized water, and 2 / 5 of the pre-emulsion was added to a reactor equipped with a stirrer, a thermometer, and a condenser, stirred and heated, and the temperature was raised to 40-80°C, and 2 / 5 of the initiator was added, and the reaction was carried out for 40 minutes Then add the remaining pre-emulsifier and initiator dropwise, continue the reaction for 6 hours after the dropwise addition is complete in 1.5 hours, cool down, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com