Elastic antifouling aqueous fluorocarbon exterior wall paint

A water-based fluorocarbon and water-based fluorocarbon emulsion technology, which is applied in the field of exterior wall latex paint, can solve problems such as inability to scrub clean, wall pollution, and rapid fading of color and gloss of the coating film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

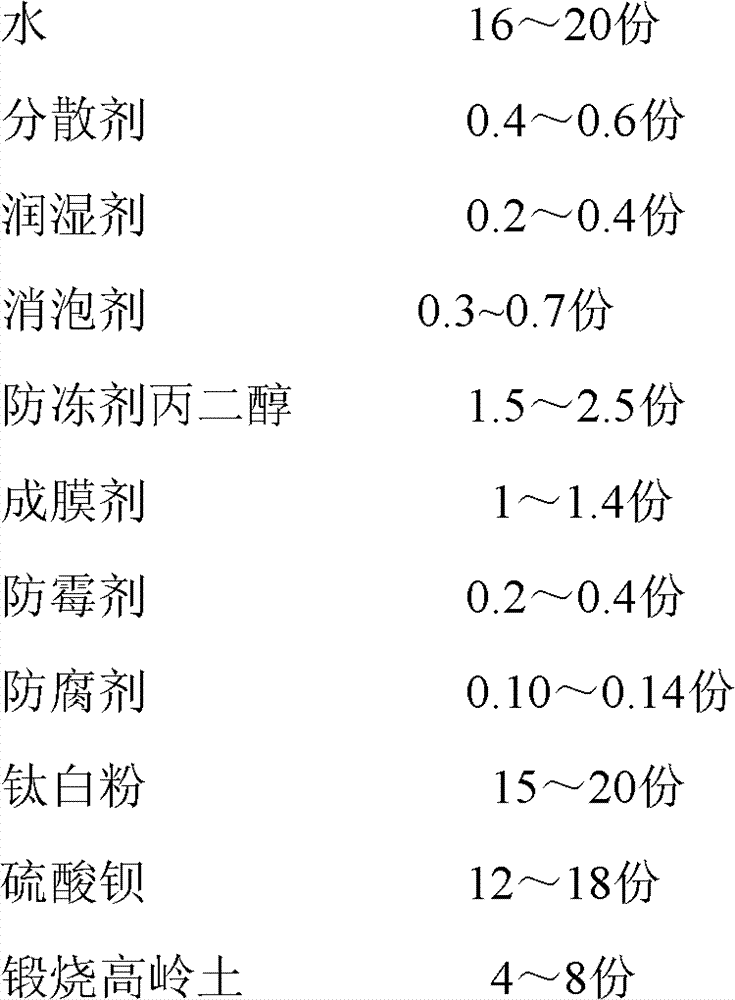

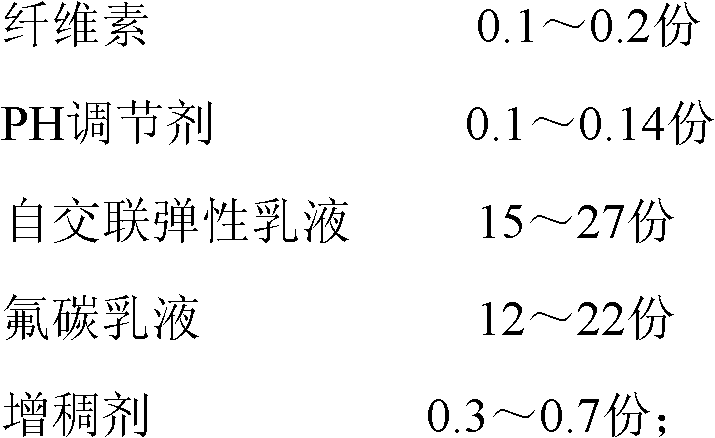

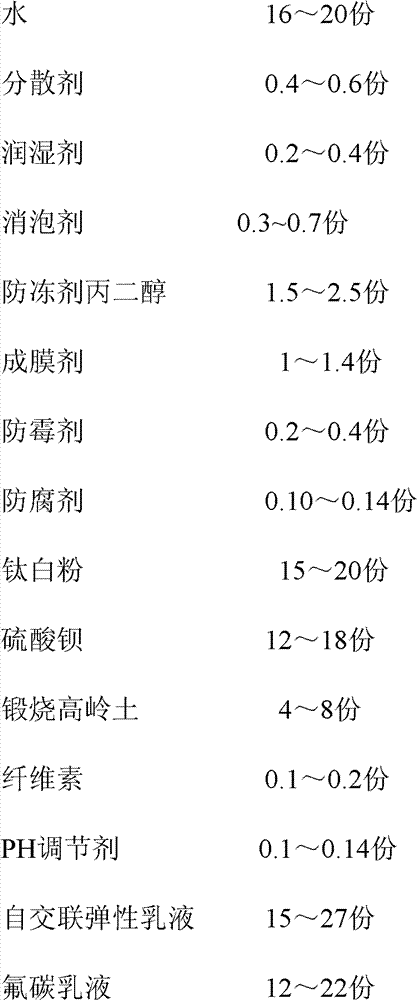

[0028] formula:

[0029] (1) Water 12.0 kg

[0030] (2) Dispersant 0.5 kg US DOWS, 963

[0031] (3) Wetting agent 0.3 kg US DOWS, CF-10

[0032] (4) Defoamer A 0.2 kg Japan NOPOCO, SN-154

[0033] (5) Antifreeze propylene glycol 2.0 kg

[0034] (6) Film-forming agent 1.2 kg American EASTMAN, TEXANOL

[0035] (7) Antifungal agent 0.3 kg US DOWS, 361

[0036] (8) Preservatives 0.12 kg US DOWS, LXE

[0037] (9) Titanium dioxide 18.0 kg, American DUPPONT R-706

[0038] (10) 2000 mesh barium sulfate 15.0 kg Jiangxi Guangyuan Chemical Co., Ltd.

[0039] (11) Calcined kaolin 6.0 kg Shanxi Hengyuan Kaolin Co., Ltd. HS-801A

[0040] (12) Cellulose 0.15 kg Germany CLARIANT, HS30000

[0041] (13) Water 2.5 kg

[0042] (14) PH, regulator 0.12 kg US DOWS, AMP-95

[0043] (15) Water 1.5 kg

[0044] (16) Self-crosslinking elastic emulsion 21.5 kg US DOWS, 2468

[0045] (17) Fluorocarbon emulsion 17.0 kg Changxing, Taiwan, 4312

[0046] (18) Thickener A 0.3 kg US DOWS, RM-8W

...

Embodiment 2

[0063] formula:

[0064] (1) Water 14.0 kg

[0065] (2) Dispersant 0.4 kg US DOWS

[0066] (3) Wetting agent 0.2 kg US DOWS

[0067] (4) Defoamer A 0.3 kg Japan NOPOCO

[0068] (5) Antifreeze propylene glycol 2.16 kg

[0069] (6) Film-forming agent 1.4 kg American EASTMAN, TEXANOL

[0070] (7) Antifungal agent 0.4 kg US DOWS, 361

[0071] (8) Preservatives 0.1 kg US DOWS, LXE

[0072] (9) Titanium dioxide 15.0 kg, American DUPPONT

[0073] (10) 2000 mesh barium sulfate 12.0 kg Jiangxi Guangyuan Chemical Co., Ltd.

[0074] (11) Calcined kaolin 8 kg Shanxi Hengyuan Kaolin Co., Ltd. HS-801A

[0075] (12) Cellulose 0.2 kg Germany CLARIANT, HS30000

[0076] (13) Water 3 kg

[0077] (14) PH, regulator 0.14 kg US DOWS, AMP-95

[0078] (15) Water 2 kg

[0079] (16) Self-crosslinking elastic emulsion 18 kg US DOWS, 2468

[0080] (17) Fluorocarbon emulsion 22 kg Changxing, Taiwan, 4312

[0081] (18) Thickener A 0.4 kg American DOWS, RM-8W

[0082] (19) Thickener B 0.1 kg US...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com