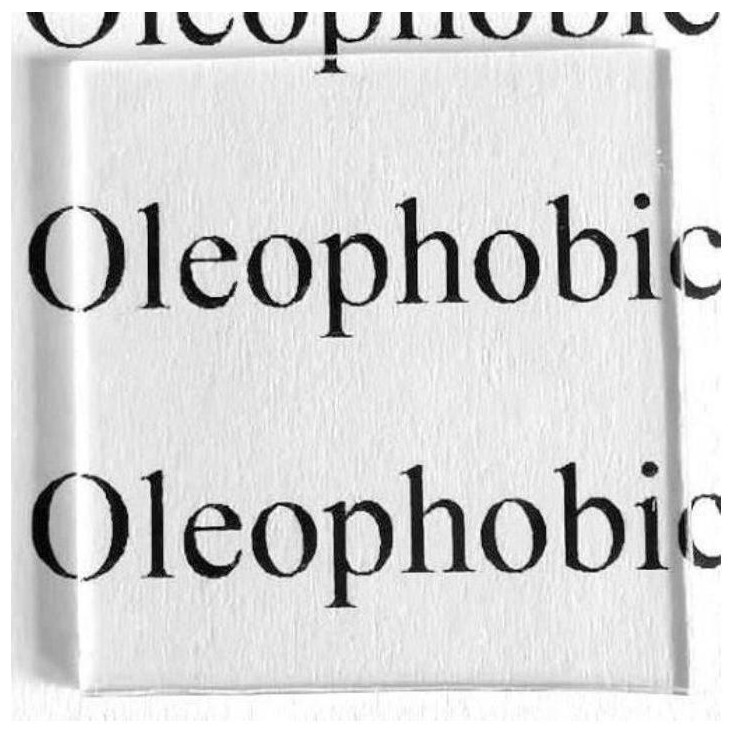

A kind of dynamic oleophobic siloxane self-enrichment epoxy coating and its preparation method and application

A technology of epoxy coating and siloxane, which is applied in the direction of epoxy resin coating, anti-corrosion coating, fire-proof coating, etc., can solve the problems of oleophobic performance failure, damage surface repellency, easy to be damaged, etc., and achieve good antifouling performance , good repellency, good oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

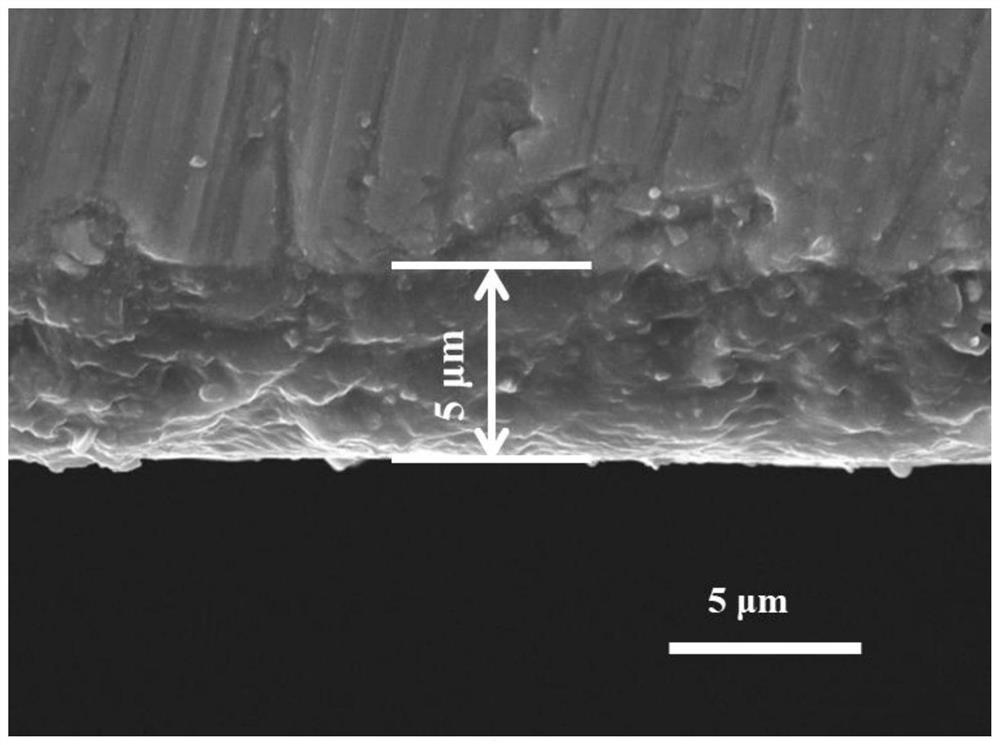

[0037] The present invention provides the preparation method of the siloxane self-concentration epoxy coating according to the above scheme, which includes the following steps: adding polysiloxane, epoxy resin and 3-aminopropyltriethoxysilane into an organic solvent Condensation reflux is performed to obtain a dynamic oleophobic siloxane self-enriching epoxy coating.

[0038] In the present invention, the temperature of the condensation reflux is preferably 80-110°C, more preferably 85-105°C, and further preferably 90-100°C; the condensation and reflux time is preferably 1-2h, more preferably 1.5 h. The condensation reflux in the present invention is preferably carried out under stirring conditions. The present invention has no special requirements for the stirring conditions, and the stirring conditions well known in the art can be used.

[0039] During the condensation reflux process of the present invention, the epoxy resin undergoes ring opening and crosslinking reaction...

Embodiment 1

[0054] Treatment of glass surface: take a piece of 25mm×25mm glass substrate, ultrasonically clean it in absolute ethanol for 30min, dry it with nitrogen, and finally treat the dried glass piece with a plasma cleaning machine for 4min.

[0055] Preparation of dynamic oleophobic silicone self-concentrating epoxy coating: amino silicone oil: epoxy resin (specifically, bisphenol A type epoxy resin): 3-aminopropyl triethoxysilane: butyl acetate = 0.01 : 1:0.02:2 mass ratio, stir with a magnetic stirrer, condensate and reflux at 90 °C for 1 h, and obtain a dynamic oleophobic siloxane self-concentration epoxy coating.

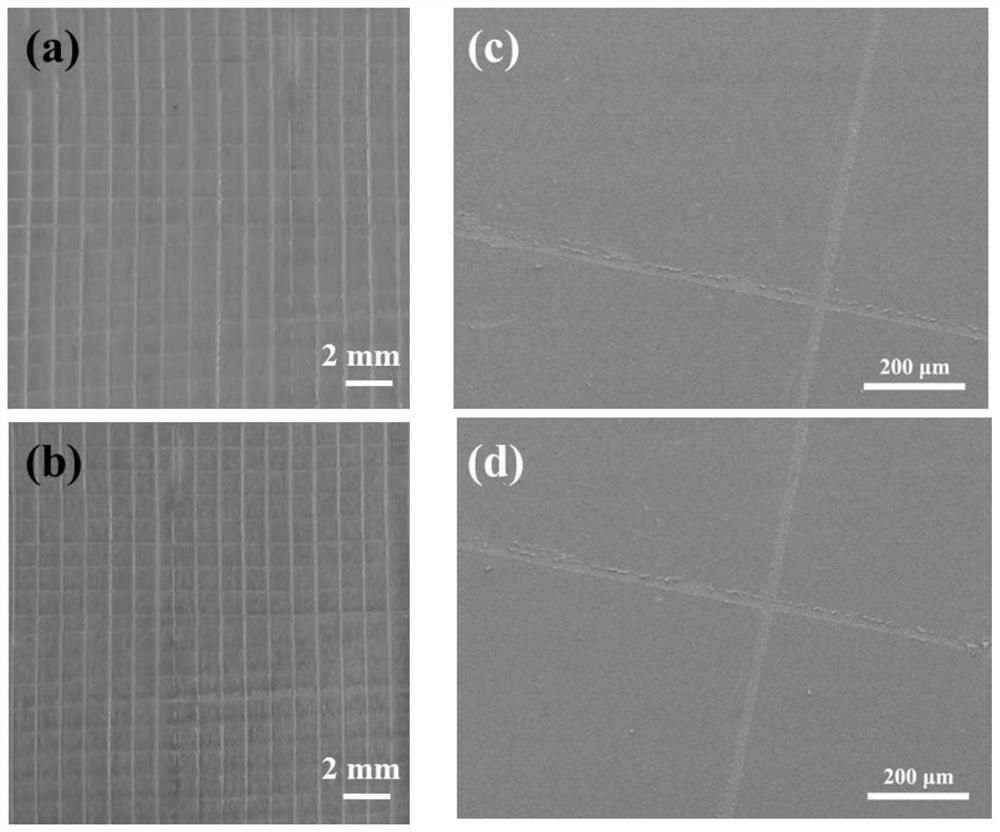

[0056] Preparation of dynamic oleophobic coating: adding a curing agent (polyetheramine D230, the mass ratio of D230 to epoxy resin is 1:2) into the dynamic oleophobic siloxane self-concentrating epoxy coating, and applying by brushing The treated glass surface is coated with a layer of siloxane self-concentration epoxy coating, and then heated at 120 °C for 30 min t...

Embodiment 2~6

[0058] The only difference from Example 1 is that the glass is replaced with a matrix of other materials, and the specific matrix and contact angle hysteresis are shown in Table 1.

[0059] Table 1 The substrates used in Examples 1-6 and the CAH values of the obtained dynamic oleophobic coatings

[0060]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com