Waterproof ventilated membrane for car light and manufacturing method thereof

A waterproof and breathable membrane and manufacturing method technology, applied in chemical instruments and methods, vehicle parts, lamination, etc., can solve the problems of inhaling pollutants, losing function, forming negative pressure, etc., and achieving the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

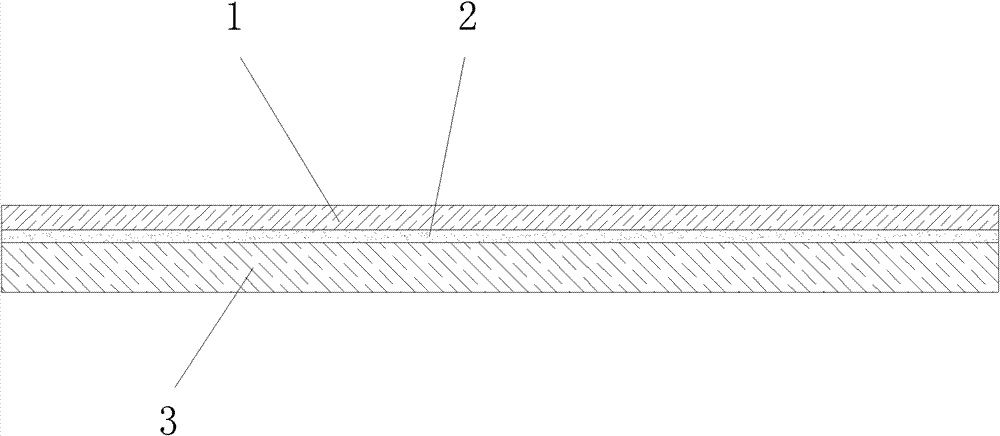

[0020] See figure 1 , the present invention is formed by composite lamination of a three-layer structure, having fabric layer invention 1 invention, waterproof breathable layer invention 3 invention and being arranged between the above fabric layer invention 1 invention and waterproof breathable layer invention 3 invention for connecting the fabric layer Invention 1 Invention and the bonding layer of the waterproof and air-permeable layer Invention 3 Invention 2 Invention, the waterproof and air-permeable layer Invention 3 is an expanded polytetrafluoroethylene film, and the specific manufacturing steps are:

[0021] a. The polytetrafluoroethylene dispersed resin is pressed into a cylindrical blank;

[0022] b. Making the cylinder blank into thin slices by calendering;

[0023] c. After removing the extrusion aid, stretching, and heat setting, the expanded polytetrafluoroethylene film is finally obtained;

[0024] d. Waterproof and oil-proof treatment of non-woven fabric: un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com