Manufacturing method of multifunctional outdoor protective fabric

A manufacturing method and multi-functional technology, applied in the direction of textiles, papermaking, textiles, fabrics, etc., can solve the problems of not being able to achieve waterproof, oil-repellent, infrared-proof, etc., and achieve good flame-retardant performance, comfortable use, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

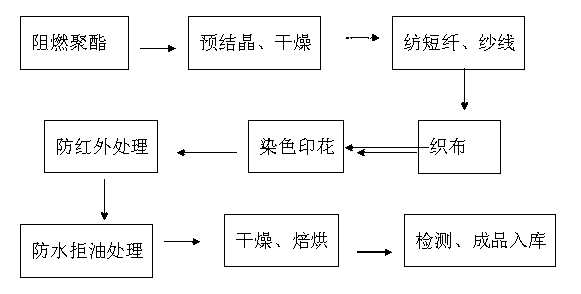

[0010] Embodiment 1: with reference to attached figure 1 . A manufacturing method (parts by mass) of a multi-functional outdoor protective fabric: (1) Select a phosphorus-based reactive permanent flame-retardant polyester with a P content greater than 8000PPM, pre-crystallize it in vacuum at 80-140°C, and dry it for 8-12 hours to reach the characteristic Viscosity ≥ 0.8dl / g, fine denier staple fiber 1 dtex X38mm, staple fiber strength ≥ 5.0CN / dtex; the staple fiber is spun into 21S spun yarn, and the warp and weft strands are used for weaving after plying; The weaving method is to weave gray cloth with a warp and weft density of 60X30; (3) finish the gray cloth after printing and dyeing, and the preparation of the finishing agent: 8-10% waterproof and oil repellent silicone fluororesin, 2-3% far-infrared nano Ceramic powder and an appropriate amount of cross-linking agent epichlorohydrin rubber (ECO) are made into an aqueous solution; (4) Post-treatment process: Put the print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Longitudinal breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com