Mothproof fabric

A fabric and insect-proof technology, applied in the field of textile fabrics, can solve the problems affecting the service life and aesthetics of fabrics, fabrics with holes or mildew, and fabrics prone to moth-eaten, etc. Good moisture conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

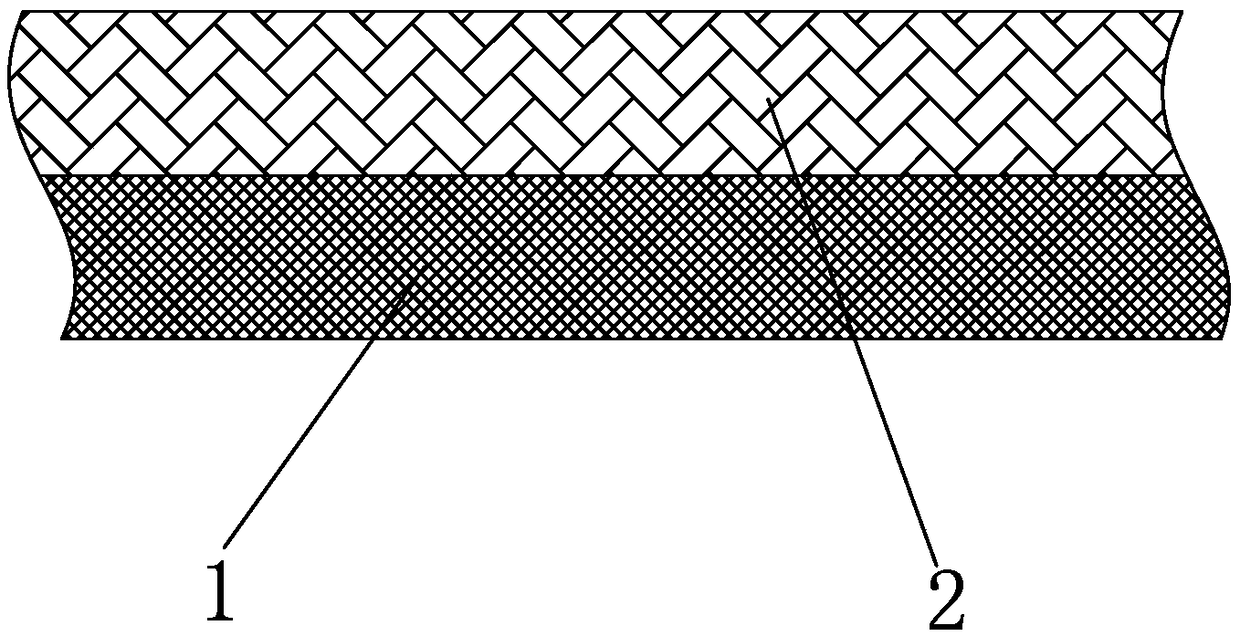

[0015] to combine figure 1 , the invention discloses an insect-proof and moth-proof fabric, which comprises a fabric body as a garment fabric. The fabric body is a double-layer fabric structure, including an inner fabric 1 and an outer fabric 2 . The inner layer fabric 1 and the outer layer fabric 2 are woven separately, and the spandex yarn is woven in series with a tuck structure. The inner layer fabric 1 adopts a 2 / 1 twill weave structure, woven with milk protein yarn as warp yarn and bamboo charcoal fiber yarn as weft yarn, which has a good touch, soft and comfortable. The outer fabric 2 adopts a plain weave structure, is woven with polypropylene fiber yarns as warp yarns, and kapok fiber yarns as weft yarns, which is crisp and wrinkle-resistant, fluffy and warm. The present invention adopts a structure with inner density and outer sparseness, which has good heat retention performance and moisture absorption and perspiration performance. The warp density of the inner lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com