High-temperature-resistant non-adhesive conveying belt and preparation method thereof

A conveyor belt, high temperature resistant technology, applied in the field of high temperature resistant non-adhesive conveyor belt and its preparation, can solve the problems of poor compatibility, material adhesion, affecting the bonding strength of the covering rubber layer and the skeleton layer, etc., to achieve high adhesion Strong, good oil-repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

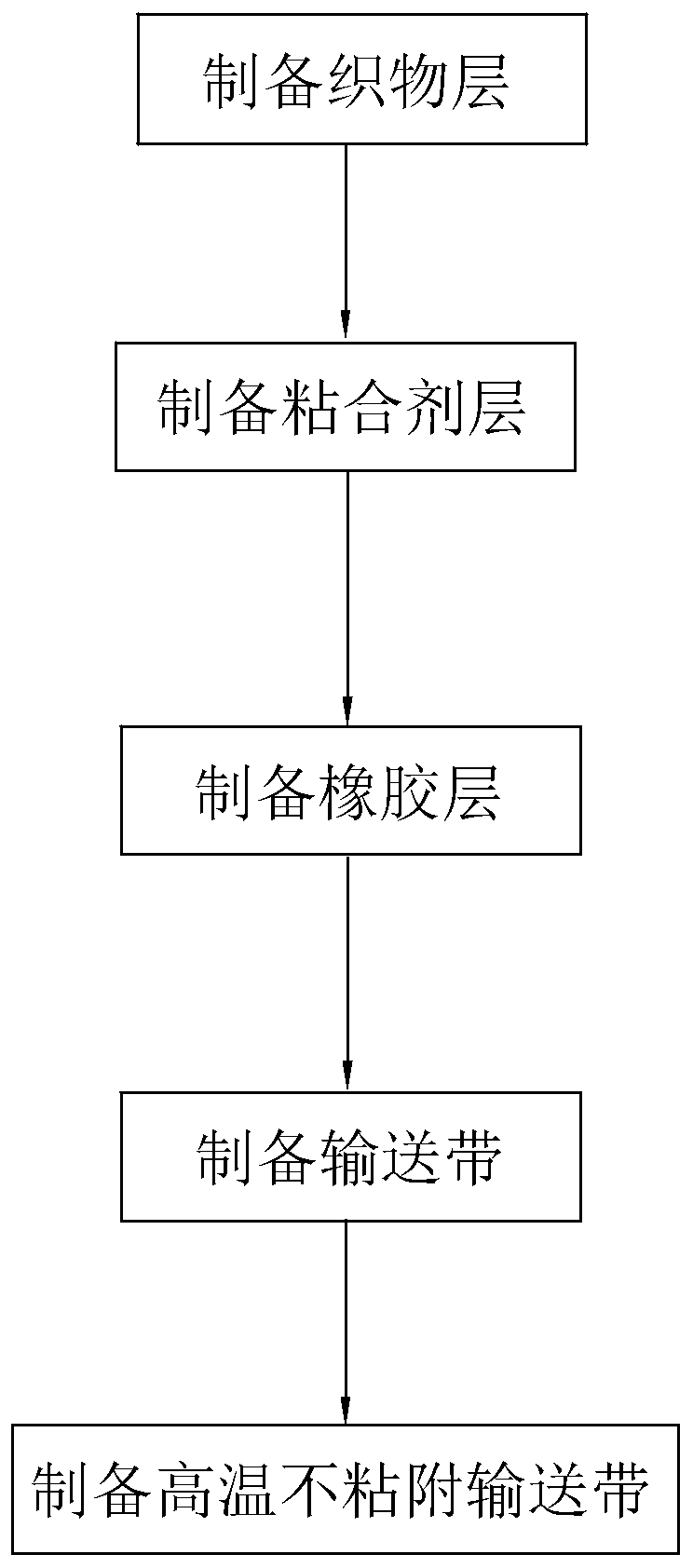

[0043] Embodiment 1: A high temperature resistant non-adhesive conveyor belt, comprising a fabric layer, an adhesive layer on both sides of the fabric layer, a rubber layer fixed on the adhesive layer, and a coating coated on the surface of the rubber layer. Wherein the material of fabric layer adopts polyester fiber, the material of adhesive layer adopts PU agent, each component and its weight parts in rubber layer are as shown in table 1. The high temperature resistant non-adhesive conveyor belt is prepared through the following steps:

[0044] S1, drying the polyester fibers at a drying temperature of 170°C, a vehicle speed of 15m / min, and a tension of 280kg to obtain a fabric layer for later use;

[0045] S2, apply PU glue evenly on the front and back of the fabric layer, the coating amount is 200g / m 2 , the vehicle speed is 15m / min, the temperature is 150°C, and the tension is 290kg, so that an adhesive layer is formed on both sides of the fabric layer;

[0046]S3, mix ...

Embodiment 2-6

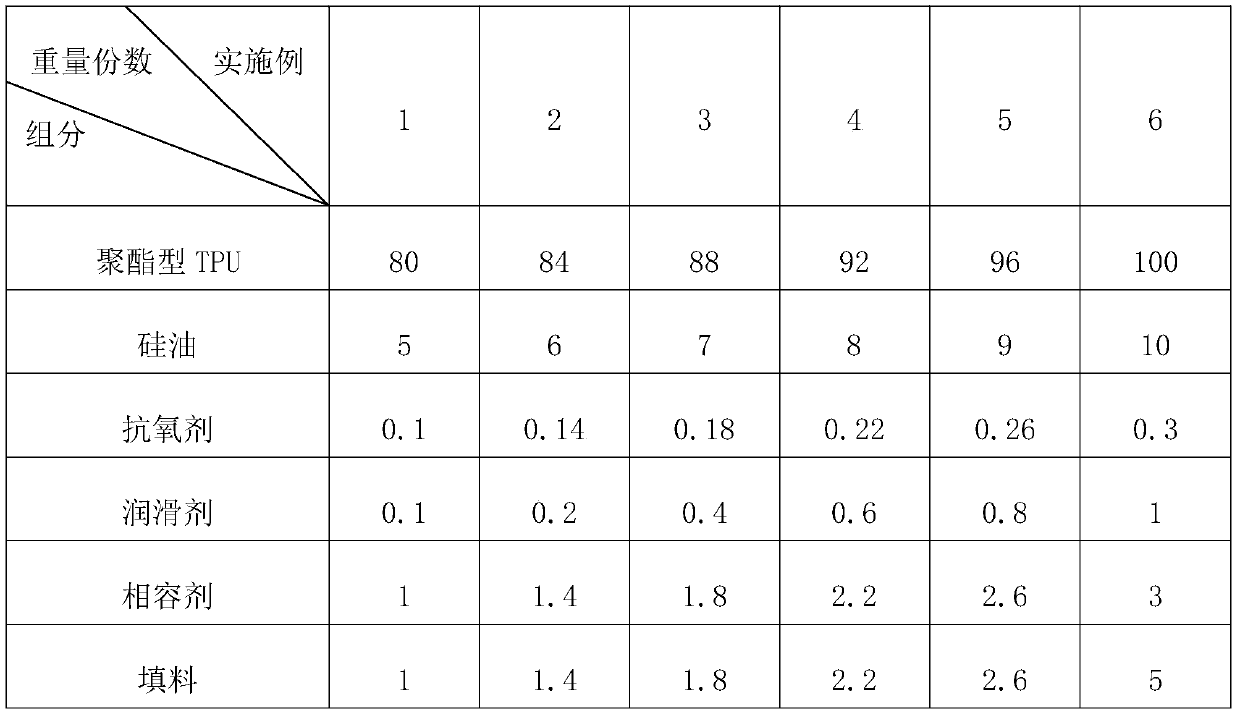

[0052] Embodiment 2-6: A high temperature resistant non-adhesive conveyor belt. The difference from Embodiment 1 is that the components in the rubber layer and their corresponding parts by weight are shown in Table 1.

[0053] Each component of rubber layer and parts by weight thereof in table 1 embodiment 1-6

[0054]

Embodiment 7

[0055] Embodiment 7: A high-temperature-resistant non-adhesive conveyor belt, the difference from Embodiment 1 is that the antioxidant uses 0.1 part of antioxidant GHT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com