Garment with anti-fouling and anti-wrinkle fabric

A technology for garments and fabrics, which is applied to the field of garments with anti-fouling and wrinkle-resistant fabrics, can solve the problems of inconvenient replacement, sloppy clothes, discounts on external impressions, etc., and achieves excellent oil-fouling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

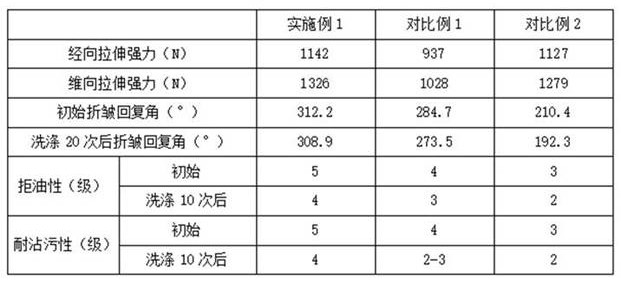

Examples

Embodiment 1

[0043] A garment with anti-fouling and wrinkle-resistant fabric, and a preparation method thereof, comprising the following steps:

[0044] (1) Preparation of modified polyamide fibers:

[0045] S1, prepare the copolymerization mixture:

[0046] Mix 4-vinylbenzeneboronic acid in a mixture of N,N-dimethylformamide and deionized water, then add trifluoroethyl methacrylate, mix and stir evenly, and place it under nitrogen as a protective gas In the reaction vessel of , stir and mix evenly, add azobisisobutyronitrile as an initiator, heat up to 75 ° C, and stir for 12 h. After the reaction, remove the solvent to obtain a copolymerization mixture; wherein, 4-vinylbenzeneboronic acid, methyl The mass ratio of trifluoroethyl acrylate, N,N-dimethylformamide and deionized water is 1.2:0.76:12:1.3, and the mass ratio of azobisisobutyronitrile to 4-vinylbenzeneboronic acid is 1.8 :100;

[0047] S2, preparation of modified polyamide fibers:

[0048] The polyamide powder and the copolyme...

Embodiment 2

[0055] A garment with anti-fouling and wrinkle-resistant fabric, and a preparation method thereof, comprising the following steps:

[0056] (1) Preparation of modified polyamide fibers:

[0057] S1, prepare the copolymerization mixture:

[0058] Mix 4-vinylbenzeneboronic acid in a mixture of N,N-dimethylformamide and deionized water, then add trifluoroethyl methacrylate, mix and stir evenly, and place it under nitrogen as a protective gas In the reaction vessel of , stir and mix evenly, add azobisisobutyronitrile as an initiator, raise the temperature to 70 °C, and stir for 10 h. After the reaction, remove the solvent to obtain a copolymerization mixture; The mass ratio of trifluoroethyl acrylate, N,N-dimethylformamide and deionized water is 1.2:0.68:10:1.1, and the mass ratio of azobisisobutyronitrile to 4-vinylbenzeneboronic acid is 1.2 :100;

[0059] S2, preparation of modified polyamide fibers:

[0060] The polyamide powder and the copolymerized mixture are mixed into ...

Embodiment 3

[0067] A garment with anti-fouling and wrinkle-resistant fabric, and a preparation method thereof, comprising the following steps:

[0068] (1) Preparation of modified polyamide fibers:

[0069] S1, prepare the copolymerization mixture:

[0070] Mix 4-vinylbenzeneboronic acid in a mixture of N,N-dimethylformamide and deionized water, then add trifluoroethyl methacrylate, mix and stir evenly, and place it under nitrogen as a protective gas In the reaction vessel of , stir and mix evenly, add azobisisobutyronitrile as an initiator, heat up to 80 ° C, and stir for 15 h. After the reaction, remove the solvent to obtain a copolymerization mixture; wherein, 4-vinylbenzeneboronic acid, methyl The mass ratio of trifluoroethyl acrylate, N,N-dimethylformamide and deionized water is 1.2:0.85:15:1.4, and the mass ratio of azobisisobutyronitrile to 4-vinylbenzeneboronic acid is 2.4 :100;

[0071] S2, preparation of modified polyamide fibers:

[0072] The polyamide powder and the copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com