Transparent phenol-free pasty heat stabilizer and preparing method thereof

A heat stabilizer, phenol paste technology, applied in the field of transparent phenol-free environmentally friendly paste heat stabilizer and its preparation, can solve the problems of limited application, phenol residue, etc., and achieve the effect of enhanced anti-oxidation performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

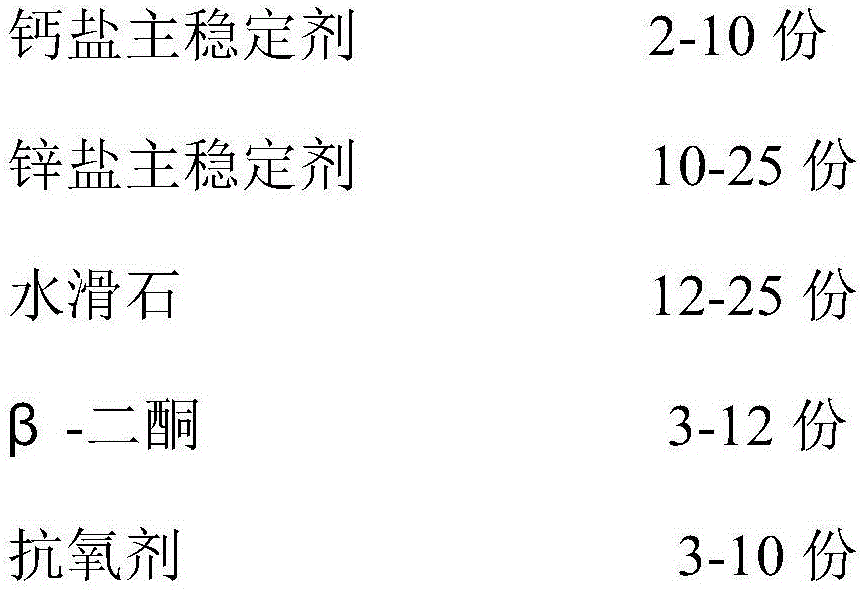

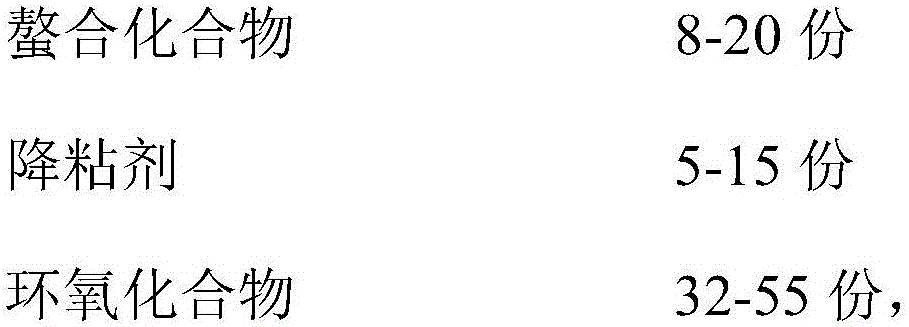

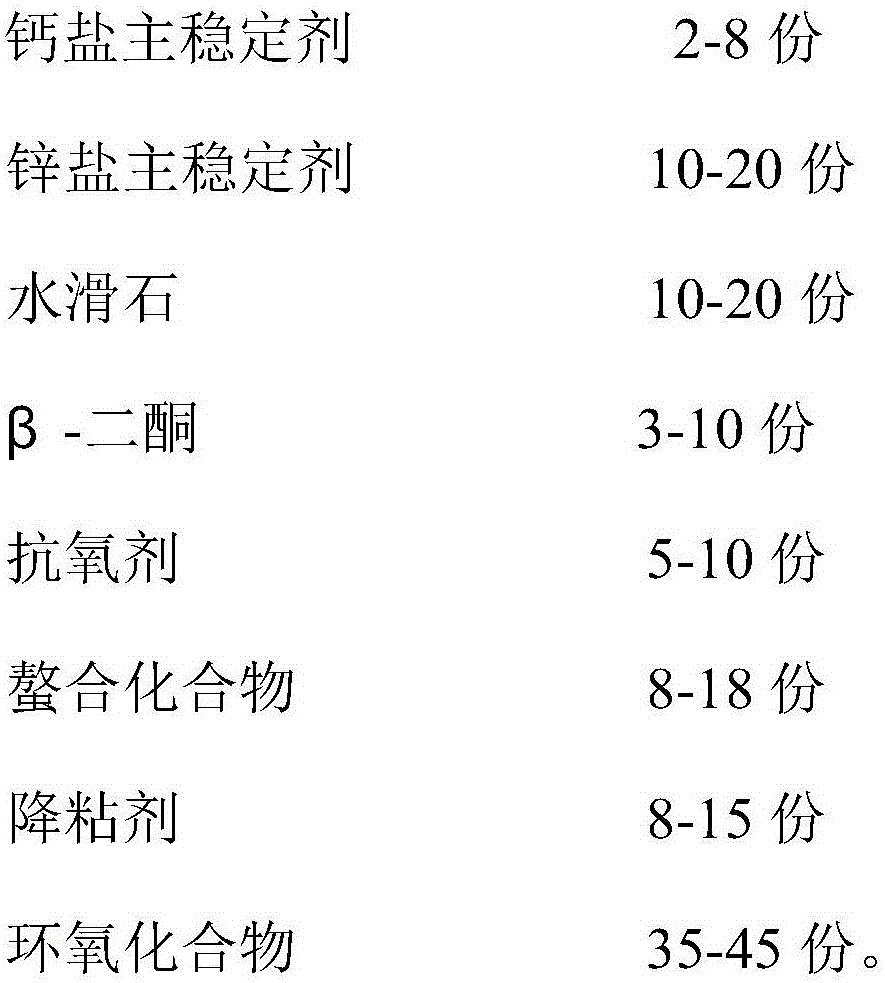

Method used

Image

Examples

Embodiment 1

[0049] Weigh 4kg distearyl pentaerythritol diphosphite, 8kg diisodecyl pentaerythritol diphosphite, 7kg2,2,4-trimethyl-1,3-pentanediol diisobutyrate, 40kg ring Oxygenated soybean oil is put into the explosion-proof high-speed mixing reactor in turn, the mixing speed is set at 600r / min, and mixed for 7min at 58°C; then 2kg of calcium stearate, 12kg of zinc stearate, and 18kg of magnesium aluminum At the same time, increase the mixing speed to 800r / min, and mix for 15min at 58°C; finally put 5kg of dibenzoylmethane, 4kg of β-(3,5-di-tert-butyl-4-hydroxy Phenyl) n-octadecanyl propionate, mixed at the same speed and temperature for 30 minutes, left to defoam at 58°C for 15 minutes, cooled the material to 35°C, and the transparent phenol-free paste of the present invention can be obtained Paste heat stabilizer.

Embodiment 2

[0051] Weigh 2,2,4-trimethyl-1,3-pentanediol diisobutyric acid of 6kg bis(octadecylaminophosphite) pentaerythritol ester, 8kg diisodecyl pentaerythritol ester of diphosphite, 8kg Ester, 37kg unsaturated fatty acid epoxy ester, put into the explosion-proof high-speed mixing reactor in turn, the mixing speed is set to 600r / min, mix 8min under the condition of 58 ℃; then put 10kg calcium stearate, 12kg zinc laurate in order , 20kg magnesium-aluminum-zinc ternary hydrotalcite, and the mixing speed is increased to 800r / min, and mixed for 20min at 58°C; finally, 4kg stearoylbenzoylmethane and 3kg tetrakis[β-(3 , 5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, mixed at the same speed and temperature for 35 minutes, left to defoam at 58°C for 10 minutes, and cooled to 35°C to obtain The transparent phenol-free paste heat stabilizer of the present invention.

Embodiment 3

[0053] Weigh 5kg di(hexadecanyl alcohol) pentaerythritol diphosphite, 8kg diisodecyl pentaerythritol diphosphite, 11kg diethylene glycol dibenzoate, 32kg epoxy butyl oleate, put into explosion-proof high-speed mixing In the reaction kettle, the mixing speed was set at 600r / min, and mixed for 8min at 58°C; then 4kg calcium stearate, 9kg zinc stearate, 4kg zinc laurate, 20kg magnesium-aluminum binary hydrotalcite were added in order, and at the same time Increase the mixing speed to 800r / min, and mix for 20min at 58°C; finally put 3kg of isovalerylbenzoylmethane, 2kg of stearoylbenzoylmethane, 4kg of β-(3,5-di-tert- Butyl-4-hydroxyphenyl) n-octadecyl propionate, mixed for 30 minutes under the same rotational speed and temperature conditions, left to defoam at 58°C for 10 minutes, and cooled the material to 35°C to obtain the present invention The transparent phenol-free paste heat stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com