Anti-sticking coating

A technology of anti-stick coating and surface layer, which is applied in the direction of coating, metal material coating technology, layered products, etc., can solve the problem of inability to use repeatedly and for a long time, affect the apparent quality of products, and increase the complexity of processing, etc. problem, to achieve the effect of large wetting angle, high temperature hardness, and reduced affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

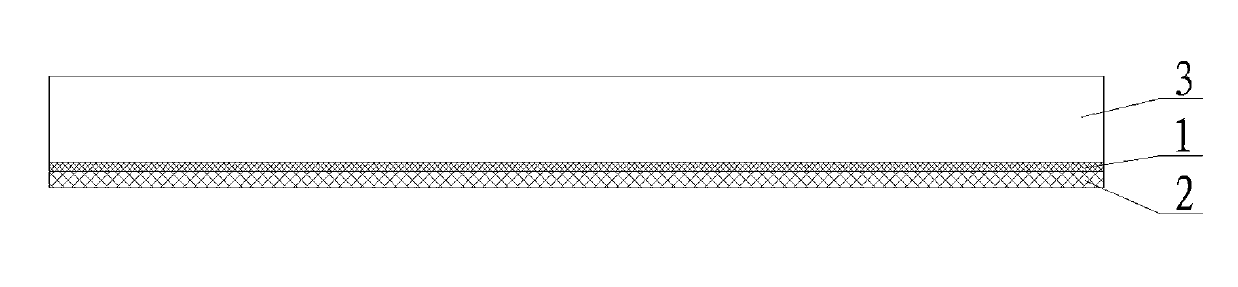

Image

Examples

Embodiment 1

[0033] Using plasma spraying equipment, the anti-sticking coating is sprayed on a roller with a diameter of 300 mm and a length of 1500 mm. Spray the NiAl primer first, the parameters are:

[0034] Hydrogen: 8(l / min)

[0035] Argon: 40(l / min)

[0036] Current: 630(A)

[0037] Spraying speed: 10(mm / s)

[0038] Cooling gas pressure: 0.4(MPa)

[0039] Bottom thickness: 0.2 (mm)

[0040] After spraying the bottom layer, and then spray the surface layer material, the powder content of the surface layer is: iron (2%), nickel (55%), chromium (5%), boron (3%), silicon (5%), manganese (0.1%) ) +30% tungsten carbide particles. The spray parameters are:

[0041] Hydrogen: 8(l / min)

[0042] Argon: 40(l / min)

[0043] Current: 630(A)

[0044] Spraying speed: 10(mm / s)

[0045] Cooling gas pressure: 0.4(MPa)

[0046] Surface layer thickness: 0.5 (mm)

[0047] Final surface roughness: Ra0.8-1.0um.

[0048] The roll with anti-stick coating is used in the production line of automot...

Embodiment 2

[0050] The anti-stick coating was sprayed on a roll with a diameter of 360 mm and a length of 1700 mm using arc spraying equipment. First spray NiCr primer, the parameters are:

[0051] Spray gun: gas wire spray gun

[0052] Oxygen: 0.8m3 / h

[0053] Acetylene: 0.5m3 / h

[0054] Compressed air: 5Kg / cm3

[0055] Spray distance: 90-110mm

[0056] Spraying the surface layer, the powder content of the surface layer is: iron (5%), nickel (60.8%), chromium (14%), boron (3%), silicon (2.9%), manganese (0.3%) + 15% carbonization Chrome particles. The spray parameters are:

[0057] Spray gun: arc spray gun

[0058] Oxygen: 0.8m3 / h

[0059] Acetylene: 0.5m3 / h

[0060] Compressed air: 5Kg / cm3

[0061] Spray distance: 90-110mm

[0062] After spraying, the coating has good performance and can meet the requirements of use, and its service life is about 5 times longer than that of Teflon-treated crankshafts.

Embodiment 3

[0064] Using plasma spraying equipment, the anti-sticking coating is sprayed on a roller with a diameter of 240 mm and a length of 1200 mm. Spray the NiCrAl primer first, the parameters are:

[0065] Hydrogen: 9(l / min)

[0066] Argon: 45(l / min)

[0067] Current: 650(A)

[0068] Spraying speed: 10(mm / s)

[0069] Cooling gas pressure: 0.6(MPa)

[0070] Bottom layer thickness: 0.18 (mm)

[0071] After spraying the bottom layer, and then spray the surface layer material, the powder content of the surface layer is: iron (10%), nickel (54%), chromium (15%), boron (7%), silicon (3.9%), manganese (0.1%) ) +10% chromium carbide particles. The spray parameters are:

[0072] Hydrogen: 10(l / min)

[0073] Argon: 46(l / min)

[0074] Current: 650(A)

[0075] Spraying speed: 10(mm / s)

[0076] Cooling gas pressure: 0.6(MPa)

[0077] Surface layer thickness: 0.6 (mm)

[0078] Final surface roughness: Ra0.8um.

[0079] After spraying, the roller surface coating is ground and polishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com