Titanium polyester catalyst for preparing polyester

A titanium-based polyester and catalyst technology, which is applied in the field of titanium-based polyester catalysts, can solve the problems of poor light stability and storage stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

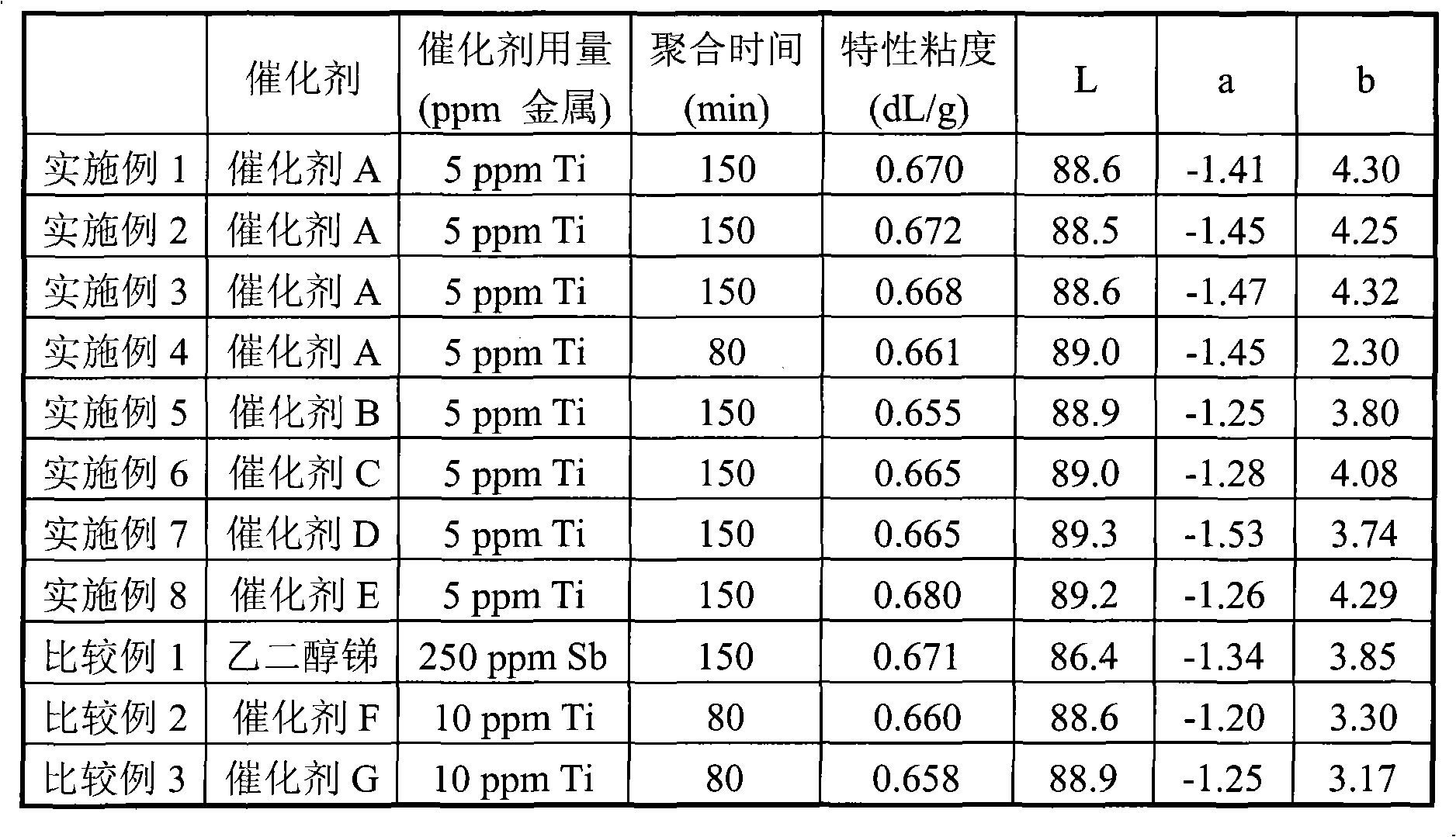

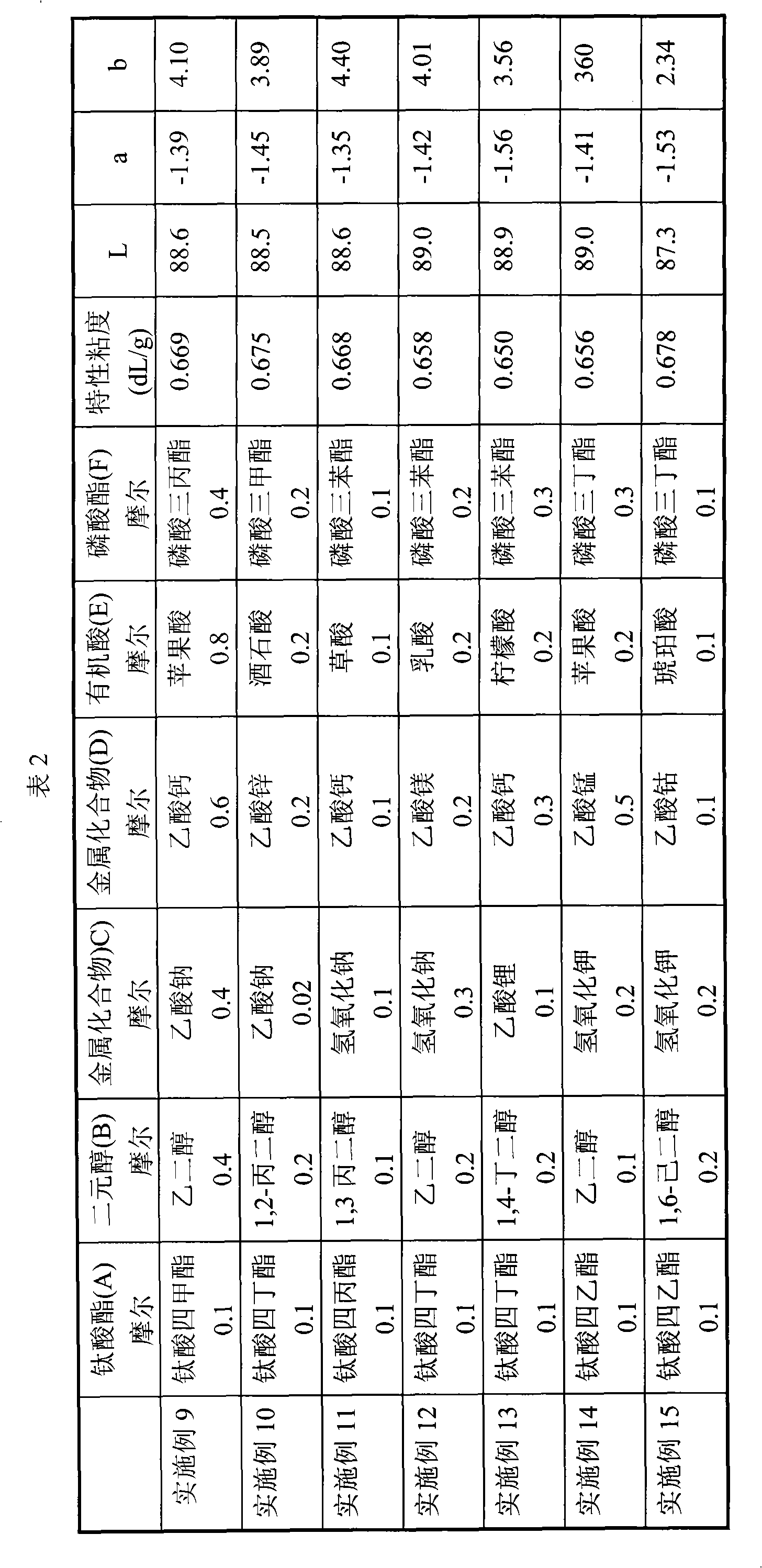

Examples

Embodiment 1

[0033] Preparation of Catalyst A

[0034] Add 12.4 grams (0.2 mol) of ethylene glycol in the reactor that stirrer, condenser and thermometer are equipped with, slowly drop into reactor 28.4 grams (0.1 mol) tetraisopropyl titanate, separate out white precipitate, After reacting at 70°C for 2 hours, the product was centrifuged, and the residue was washed with distilled water three times, and the product was vacuum-dried at 70°C. A white powdery substance was obtained.

[0035] Place the dried white powdery substance in a reactor with a stirrer, a condenser and a thermometer, add 50 grams of ethylene glycol, 32 grams of 25% aqueous sodium hydroxide solution (0.2 moles), magnesium acetate tetrahydrate 21.4 gram (0.1 mole), 21 grams (0.1 mole) of citric acid monohydrate, and 14 grams (0.1 mole) of trimethyl phosphate were reacted for 2 hours at a reaction temperature of 150° C. to obtain a nearly colorless homogeneous liquid, which was catalyst A.

[0036] Preparation of polyester ...

Embodiment 2

[0040] Catalyst A was placed under strong sunlight and irradiated continuously for 3 months. No change in the color and appearance of the catalyst was found. The catalytic performance was tested again. The results are shown in Table 1.

Embodiment 3

[0042] Catalyst A was placed in the room without being protected from light for one and a half years, and no change in the color and appearance of the catalyst was found. The catalytic performance was tested again, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com