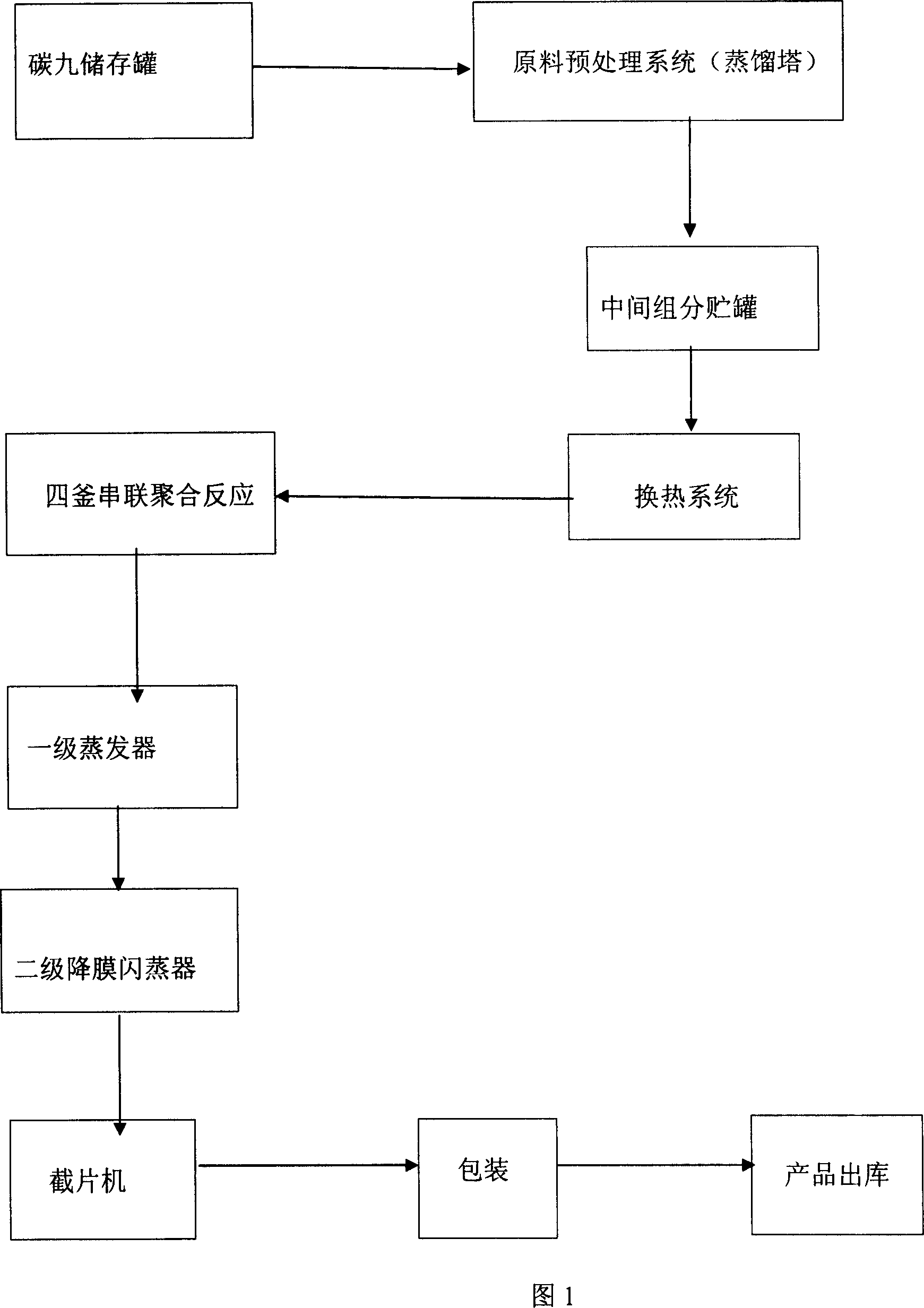

Technique for producing petroleum resin of carbon - 9 through continuous hot polymerization in cascade connected multiple kettles

A carbon-9 petroleum resin and multi-tank series-connected technology is applied in the field of multi-tank series continuous thermal polymerization to produce carbon-9 petroleum resin technology, which can solve the problems of low output, single variety, unstable quality, etc. The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] (1) Turn on the pump to feed the material, use the circulation valve to adjust the feed rate to gradually increase at about 1500L / h, start to feed the distillation tower, and determine the opening of the heat transfer oil valve of the preheater and reboiler according to the temperature in the tower The temperature of the feed section is controlled at about 135°C.

[0014] At the beginning, there is no liquid level at the bottom of the tower (high vacuum, high feed temperature, and light components of the material flow out quickly), pay attention to the liquid level of the buffer tank of the side line product and the reflux tank at the top of the fractionation tower, and start to implement total reflux operation. After that, slowly transfer to the control of normal operating parameters.

[0015] When the temperature at the bottom of the tower shows the liquid level, control the temperature at the bottom of the tower at 170°C to 180°C, control the temperature at the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com