Flame-retardant polyester and process for producing the same

A flame-retardant polyester technology, applied in the field of flame-retardant polyester, can solve the problems of increased yellow coloration of polymers, unusable high whiteness, and poor productivity, achieving good hue, high industrial value, and mechanical Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

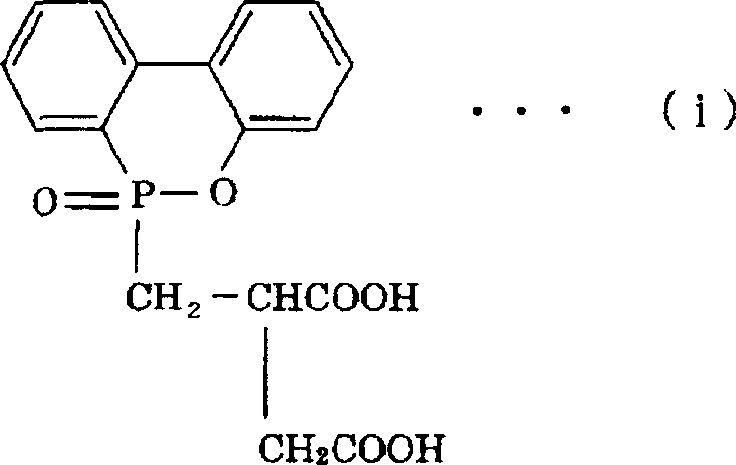

[0108] A stainless steel autoclave equipped with a stirrer, a distillation tower, and a pressure regulator (all the equipment used in the following experiments) was charged with 825 parts of terephthalic acid, 4 parts of trimellitic acid, and 1006 parts of phosphorus compound (i) (As a 50% ethylene glycol solution) and 297 parts of ethylene glycol, then add 0.324 parts of germanium dioxide and 2.1 parts of triethylamine, at 245℃, gauge pressure 2.5kg / cm 2 The esterification reaction was carried out for 2 hours while successively removing the water produced by the esterification. Next, the temperature of the system was increased to 280°C over 1 hour, and during this time, the pressure of the system was gradually reduced to reach 0.1 mmHg, and the polycondensation reaction was carried out for 105 minutes under these conditions. The phosphorus content of the obtained polymer was 30000 ppm, which showed good flame retardancy. In addition, even with high concentrations of phosphorus, t...

Embodiment 2

[0110] A stainless steel autoclave equipped with a stirrer, a distillation tower, and a pressure regulator (all the equipment used in the following experiments) was charged with 825 parts of terephthalic acid, 4 parts of trimellitic acid, and 1006 parts of phosphorus compound (i) (As a 50% ethylene glycol solution) and 297 parts of ethylene glycol, then add 0.324 parts of germanium dioxide and 2.1 parts of triethylamine, at 245℃, gauge pressure 2.5kg / cm 2The esterification reaction was carried out for 2 hours while successively removing the water produced by the esterification. Next, the temperature of the system was increased to 280°C over 1 hour, and during this time, the pressure of the system was gradually reduced to reach 0.1 mmHg, and the polycondensation reaction was carried out for 105 minutes under these conditions. The phosphorus content of the obtained polymer was 30000 ppm, which showed good flame retardancy. In addition, even with high concentrations of phosphorus, th...

Embodiment 3

[0112] 821 parts of terephthalic acid, 7 parts of trimellitic acid, 1005 parts of phosphorus compound (i) (as a 50% ethylene glycol solution), and 296 parts of ethylene glycol are charged, and 0.324 parts of germanium dioxide and three are added. 2.1 parts of ethylamine, at 245℃, gauge pressure 2.5kg / cm 2 The esterification reaction was carried out for 2 hours while successively removing the water produced by the esterification. Next, the temperature of the system was increased to 280°C over 1 hour, and during this time the pressure of the system was gradually reduced to 0.1 mmHg, and the polycondensation reaction was carried out for 105 minutes under these conditions. The phosphorus content of the obtained polymer was 30000 ppm, which showed good flame retardancy. In addition, even with high concentration of phosphorus, the intrinsic viscosity is as high as 0.89dl / g. That is, it means that the polymerization speed is fast. The melt viscosity of the polymer is 16780 dPa·s, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com