Stiff polypropylene composition with excellent elongation at break

A polypropylene composition and polypropylene technology, applied in the field of new polypropylene compositions, can solve problems affecting the ductility of polypropylene and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

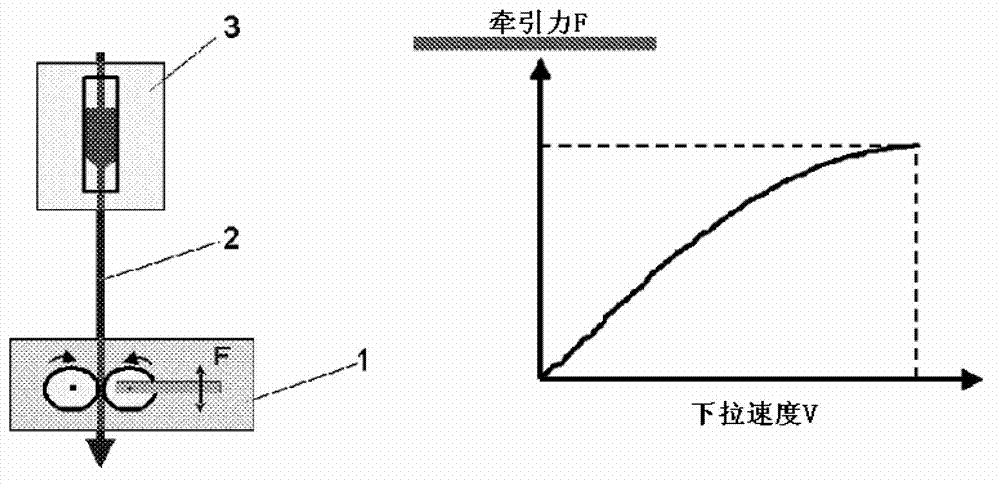

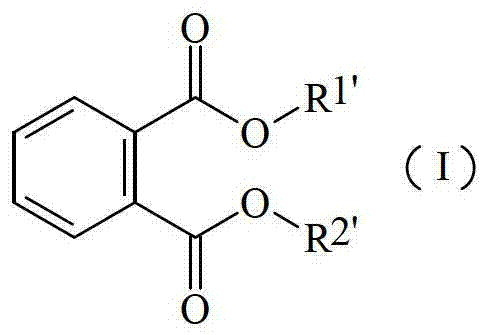

[0279] Preparation of the catalysts described herein can be performed batchwise, semi-continuously, or continuously. In a semi-continuous process or a continuous process, the complex solution of the Group 2 metal and the electron donor is prepared by reacting the compound of the metal with the electron donor in an organic liquid reaction medium, and the complex The compound solution is mixed with at least one transition metal compound, which may be dissolved in the same or a different organic liquid reaction medium. The solution thus obtained is then stirred, possibly in the presence of an emulsion stabilizer, and the stirring emulsion is then fed into a temperature gradient reactor in which the emulsion is subjected to a temperature gradient such that Causes the solidification of the dispersed phase droplets in the emulsion. TMA is preferably included in the complex solution, or TMA is added to the solution before feeding the stirred solution to the temperature gradient reac...

Embodiment

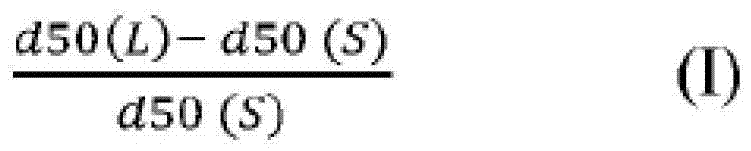

[0313] A. Measurement method

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com