Preparation method of 1,3-dioleoyl-2-palmitoyl triglyceride

A technology of palmitic acid triglyceride and palmitic glyceride, which is applied in 1 field, can solve the problems of long production cycle, large amount of enzyme used, and low energy consumption, and achieve short reaction time, small amount of enzyme used, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

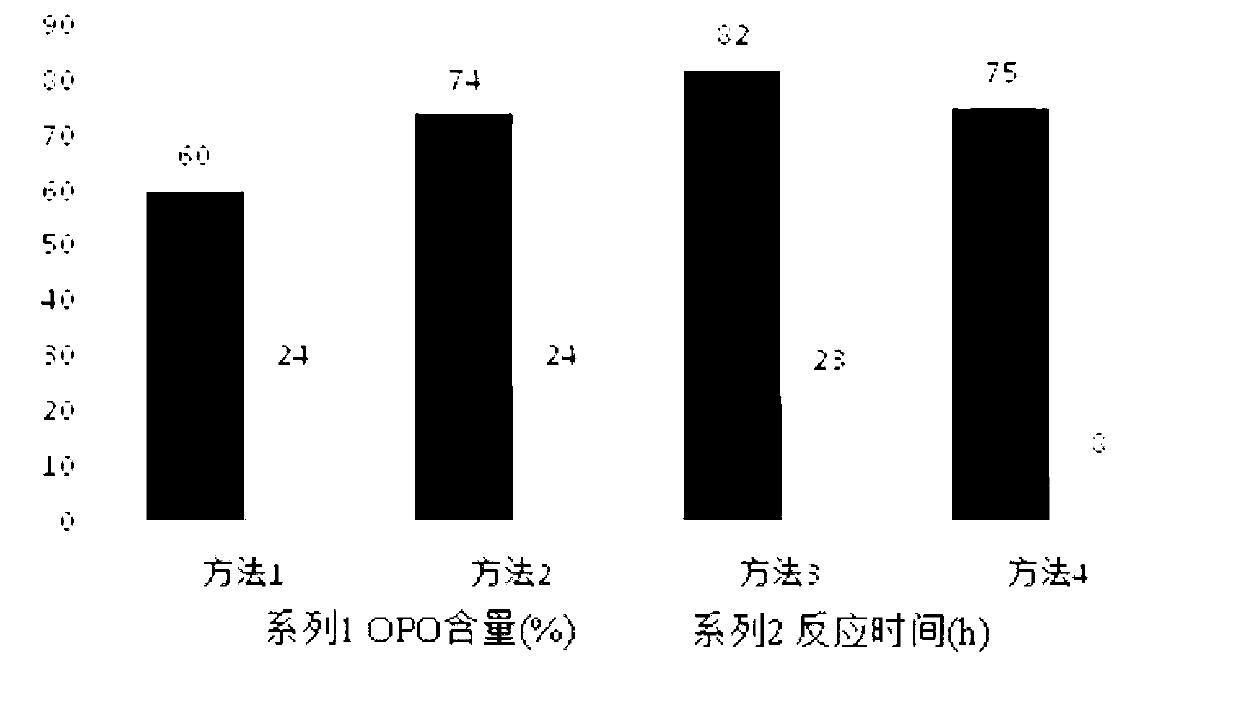

Examples

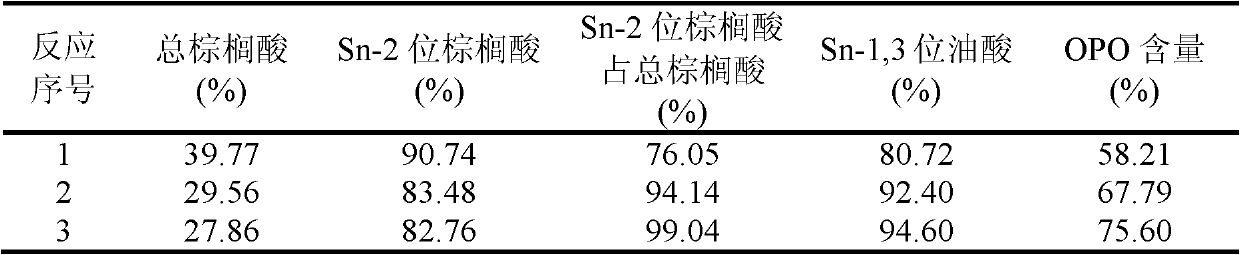

Embodiment 1

[0047] Embodiment 1 prepares OPO

[0048] (1) Mix 0.1mol of the reaction substrate glycerol and 0.6mol of palmitic acid, add catalyst NaOH (accounting for 0.5% of the total weight of the reaction substrate), and place it in a four-necked round-bottomed flask; place the round-bottomed flask on a constant temperature heating mantle Add a stirring paddle, the stirring speed is 150 rpm, the reaction temperature is 200°C, and the reaction is for 2 hours. During the reaction, nitrogen gas is continuously fed as a protective gas; after the reaction is completed, the free fatty acid in the reaction product is removed with KOH-water alcohol solution;

[0049] Detected by gas phase (FID detector, high-temperature capillary column), the content of tripalmitin in the reaction product is 92.2%, and the content of dipalmitin is 6.6%.

[0050] (2) Take 0.005mol of the reaction product prepared in step (1) (containing 92.2% tripalmitin), 0.03mol of oleic acid (85.8% of oleic acid content) and...

Embodiment 2

[0053] Embodiment 2 prepares OPO

[0054] (1) 1mol of the reaction substrate glycerol and 5mol of palmitic acid are mixed, and the catalyst p-toluenesulfonic acid (accounting for 0.5% of the total weight of the reaction substrate) is added, and placed in a four-necked round-bottomed flask; the round-bottomed flask is placed in a constant temperature heating In the sleeve, add a stirring paddle, the stirring speed is 160 rpm, the reaction temperature is 240°C, and the reaction is for 1 hour. During the reaction, nitrogen gas is continuously fed as a protective gas; after the reaction is completed, the tripalmitin in the product is purified by molecular distillation. ;

[0055] Detected by HPLC (ELSD detector, strong polar ion exchange column), the content of tripalmitin in the product is 98.7%.

[0056] (2) Take 0.05mol of the reaction product prepared in step (1) (containing 98.7% tripalmitin), 0.3mol of oleic acid (95.6% of oleic acid content) and immobilized 1,3-specific li...

Embodiment 3

[0059] Embodiment 3 prepares OPO

[0060] (1) Mix 0.1 mol of the reaction substrate glycerin, 0.8 mol of palmitic acid, Novozym 435 (Novozymes, Denmark) (accounting for 12% of the total weight of the reaction substrate), add in 1L of n-hexane, and react at a temperature of 50°C. 8h; after the reaction is completed, remove free fatty acid with KOH-hydroalcoholic solution;

[0061] Detected by GC (FID detector, high temperature capillary column), the content of tripalmitin in the product is 89.4%.

[0062] (2) get 0.005mol step (1) to prepare the reaction product (containing 89.4% tripalmitin glyceride), 0.03mol oleic acid (oleic acid content 95.6%) and Lpase DF (Japan Amano company) (accounting for reaction substrate 10% of the total weight), reacted in an enzyme reactor at 40° C. for 5 h; centrifuged the reaction mixture, took the supernatant to remove free fatty acids, and added it back to the reactor together with the bottom enzyme. Now measure palmitic acid content 43.2% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com