Method for preparing biocarbon solid acid catalyst and biodiesel

A solid acid catalyst, biodiesel technology, applied in physical/chemical process catalysts, chemical instruments and methods, biofuels, etc., can solve the problems of increased production cost, complex preparation process, fast catalyst deactivation, etc. The preparation process is simple and the effect of simplifying the pretreatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

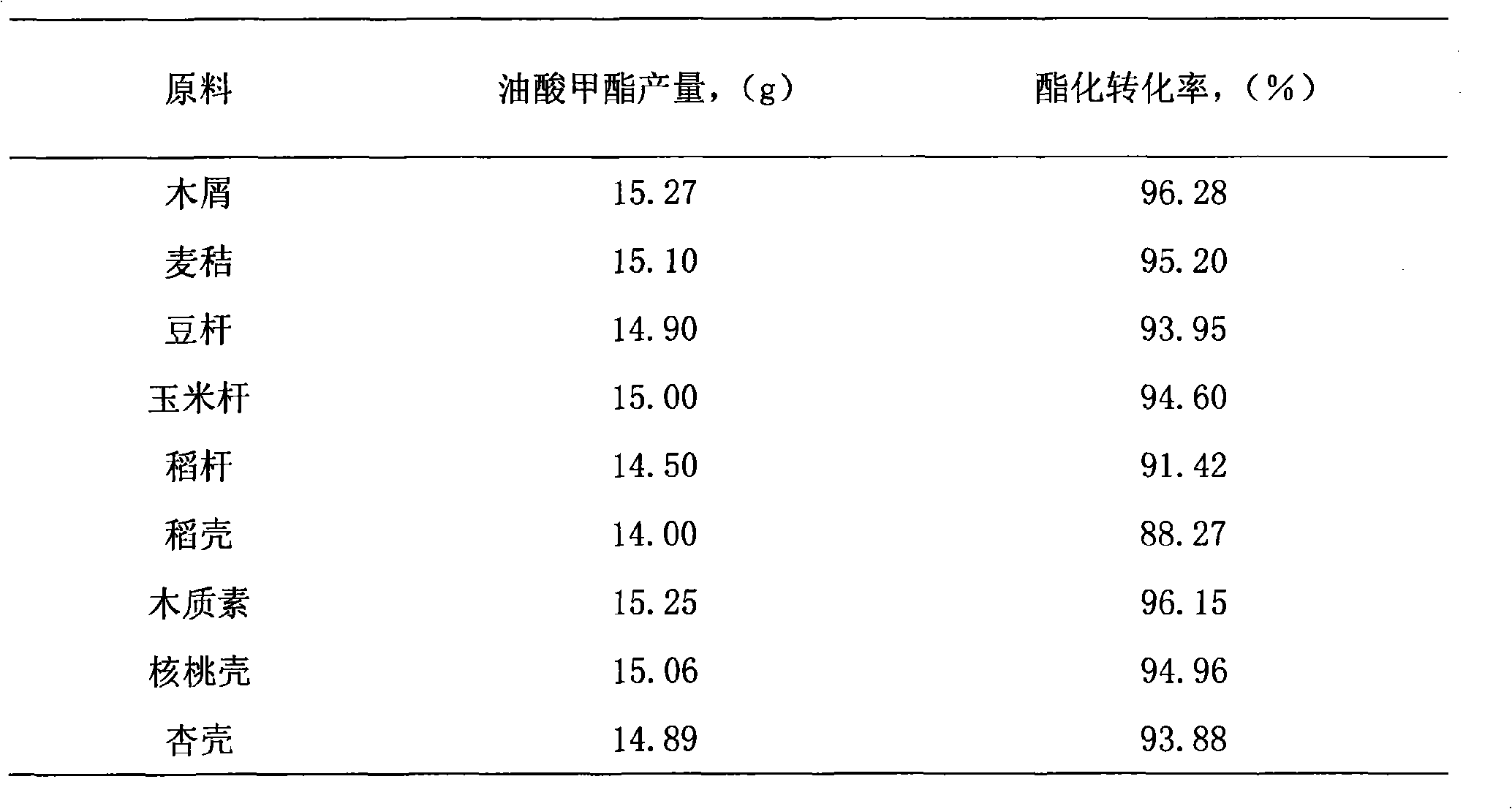

[0021] Take 30g of wood chips, wheat straw, bean stalks, corn stalks, rice stalks, lignin, rice husks, walnut shells, and apricot husks and put them into a carbonization furnace respectively, feed nitrogen gas and carbonize at 380°C for 4 hours to obtain dark brown solids, and then Oxidize at 300°C for 0.5h, take 5g of dark brown solid and sulfonate concentrated sulfuric acid at a constant temperature of 140°C for 2 hours, after the reaction, cool the solid naturally and add it to 250ml of distilled water for filtration, and then wash it with 100°C distilled water to medium The bio-based carbonaceous solid acid catalyst can be obtained after drying.

[0022] Catalytic effect: put 14g of methanol, 15.86g of oleic acid and 1g of carbonaceous catalyst in the continuous distillation-water separation esterification device to carry out esterification reaction at 90°C (reboiler temperature is 85°C), after 2 hours of reaction Obtain methyl oleate yield and esterification conversion ra...

Embodiment 2

[0026] Take 30g of chips and put them into a carbonization furnace, feed nitrogen gas and carbonize at 400°C for 4 hours to obtain a dark brown solid, then oxidize at 300°C for 0.5h, take 5g of dark brown solid and concentrated sulfuric acid for sulfonation at a constant temperature of 130°C for 5 hours After the reaction, the solid was naturally cooled and added to 250 ml of distilled water to filter, then washed with 100°C distilled water until neutral, and dried to obtain a bio-based carbon solid acid catalyst.

[0027] Catalytic effect: put 14g of methanol, 15.86g of oleic acid and 1g of carbonaceous catalyst in the continuous distillation-water separation esterification device to carry out esterification reaction at 90°C (reboiler temperature is 85°C), after 2 hours of reaction 15.21 g of methyl oleate was obtained, and the esterification rate was 95.90%.

Embodiment 3

[0029] Take 30g of sawdust and put it into a carbonization furnace, feed nitrogen gas and carbonize at 350°C for 15 hours to obtain a dark brown solid, then oxidize it at 250°C for 1 hour, take 5g of dark brown solid and concentrated sulfuric acid for sulfonation at a constant temperature of 150°C for 2 hours, After the reaction, the solid was naturally cooled and added to 250 ml of distilled water for filtration, then washed with 100°C distilled water until neutral, and dried to obtain a bio-based carbon solid acid catalyst.

[0030] Catalytic effect: put 14g of methanol, 15.86g of oleic acid and 1g of carbonaceous catalyst in the continuous distillation-water separation esterification device to carry out esterification reaction at 90°C (reboiler temperature is 85°C), after 2 hours of reaction 15.34 g of methyl oleate was obtained, and the esterification rate was 96.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com