Shock absorber with intelligent automatic pre-pressure adjusting function

An automatic adjustment and preload technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of small damping range of shock absorbers, large load changes, and sacrifice of comfort, etc., to meet the requirements of Comfort requirements and the effect of reducing the modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

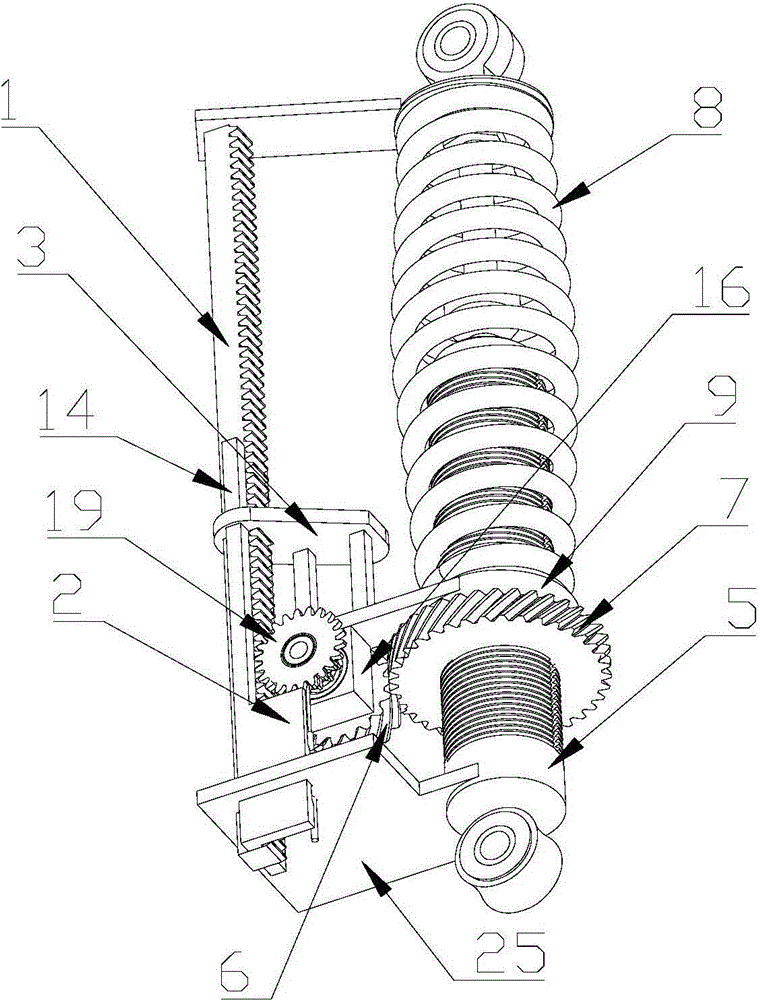

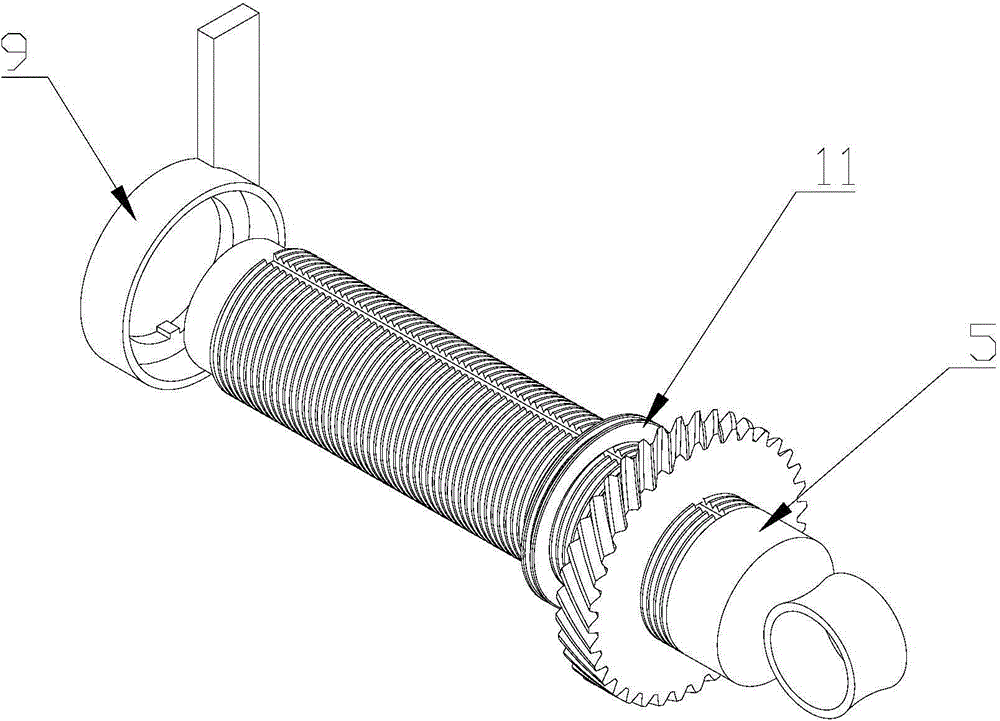

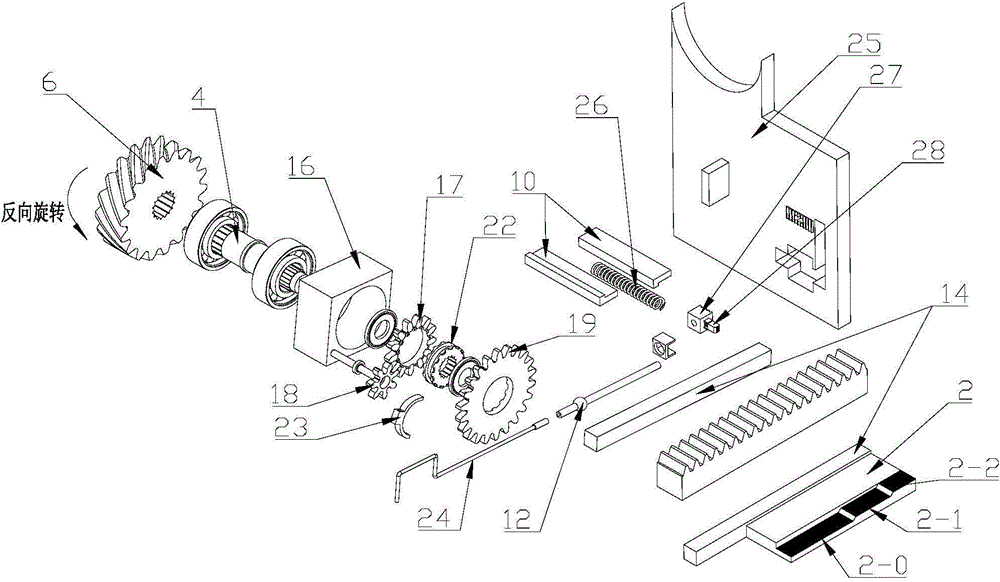

[0024] A shock absorber with the function of intelligently and automatically adjusting the preload, comprising a damping rod composed of a first telescopic part 5 and a second telescopic part, the first telescopic part 5 is a piston cylinder, the second telescopic part is a piston rod, and the damping rod Upper cover damping spring 8, one end of damping spring 8 is space-limited with the limit structure on the first telescopic part 5, and the other end of shock-damping spring 8 is space-limited with the position-limiting structure on the second telescopic part. The limit structure on the telescopic part 5 is the lifting seat 9, which can be lifted up and down with the first telescopic part 5, and the first telescopic part 5 of the damping rod has an adjusting thread and an adjustment screw sleeved on the telescopic part. The adjusting gear 7 fitted with thread, the adjusting gear 7 drives the lifting seat 9 to go up and down, adjusts the pre-pressure of the shock absorbing spri...

Embodiment 2

[0038] Compared with Embodiment 1, the first driven gear 17 and the third driven gear 19 have a one-way clutch mechanism inside, so that the first driven gear 17 and the third driven gear 19 only move up and down on the main rack 1. Reverse rotational movements can be output to the reversing gears 22, respectively. The three step surfaces on the gear plate 2 are set from high to low, and the height of the upshift position 2-0 is the highest, so as to ensure that the correct shift lever 24 is correctly shifted.

Embodiment 3

[0040] Such as figure 1 , 2 , 3, 4, and 5, compared with Embodiment 1, the contact surface between the toggle switch 27 and the fixed seat 25 has a rough surface that can provide a certain friction force to overcome the reset force of the switch spring 26. In the toggle switch The head of 27 is provided with retractable pointer 28, is provided with the pointer spring that is used for telescopic reset between pointer 28 and shift switch 27, has drag shift shift switch 27 to compress on the contact surface of pointer 28 and gear plate 2 Or break away from the rough surface of the fixing seat 25, the elastic force of the switch spring is greater than the elastic force of the pointer spring.

[0041] This scheme can reduce the shifting frequency of the shift paddle 24 .

[0042] When the shock absorber rises, the main rack 1 drives the gear plate 2 to rise together, and the gear plate 2 will squeeze the shift switch 27 when it moves upward, causing the shift switch 27 to move le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com