Safety valve

A safety valve and valve sleeve technology, which is used in mining equipment, earth-moving drilling, pillars/supports, etc., can solve the problems of slow dynamic response, damage and influence of pillars and top beam components, and achieve the reduction of elastic coefficient and dynamic response. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

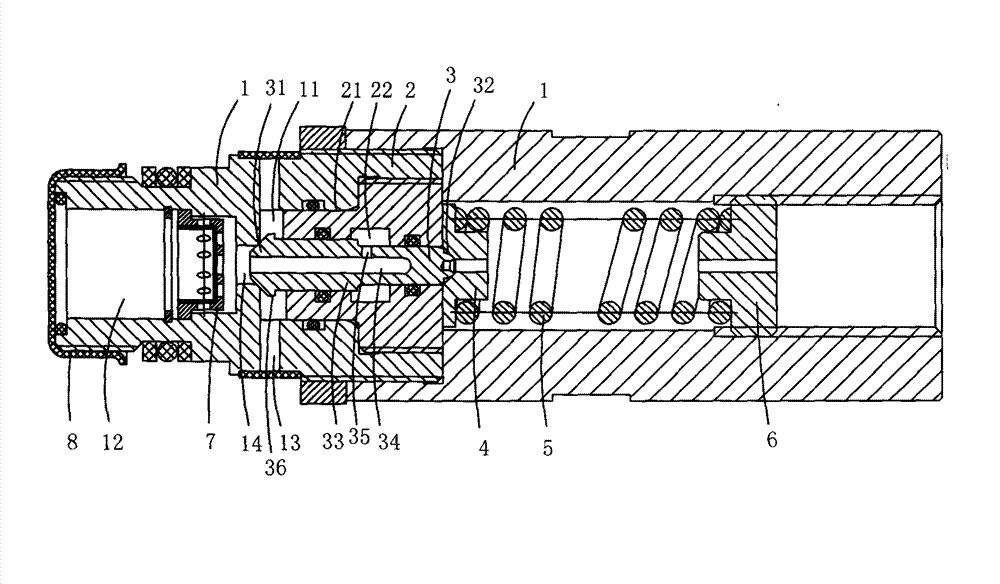

[0014] figure 1 It is a structural schematic diagram of the present invention, showing a specific embodiment of the present invention.

[0015] This embodiment is a safety valve, see figure 1 As shown, it includes a valve body 1 with a valve chamber 11, and a valve sleeve 2, a valve core 3, a spring seat 4, a spring 5 and a pressure regulating screw 6 arranged in the valve chamber 11; the valve body 1 is also provided with The liquid inlet channel 12, the liquid outlet channel 13, and the valve hole 14 for connecting the liquid inlet channel 12 and the liquid outlet channel 13; the center of the valve sleeve 2 is provided with a sliding hole 21 and a pressure valve located in the middle of the sliding hole 21 Cavity 22; one end of the valve core 3 is provided with a sealing portion 31 for blocking the valve hole 14, the other end is provided with a pressing portion 32 for pressing against the spring seat 4, and the middle end is provided for pressing on the valve hole 14. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com