Centrifugal speed regulator device for preventing pulsation

A technology of centrifugal speed governor and hydraulic cylinder, which is applied in transmission devices, transmission parts, fluid transmission devices, etc. It can solve problems such as excessive impact, different quality, and influence on the operation process, so as to reduce excessive impact and make it easy to use effect, the effect of eliminating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

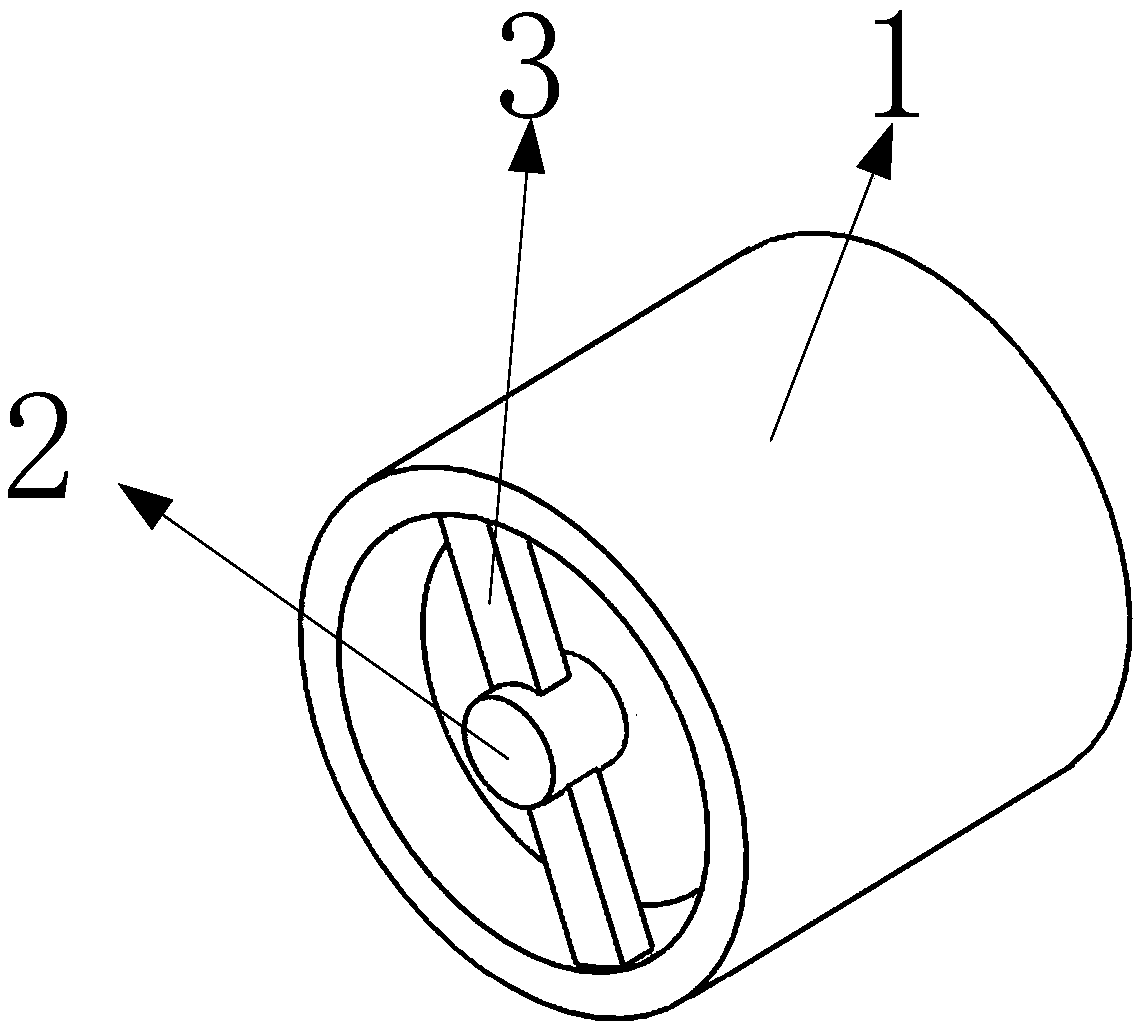

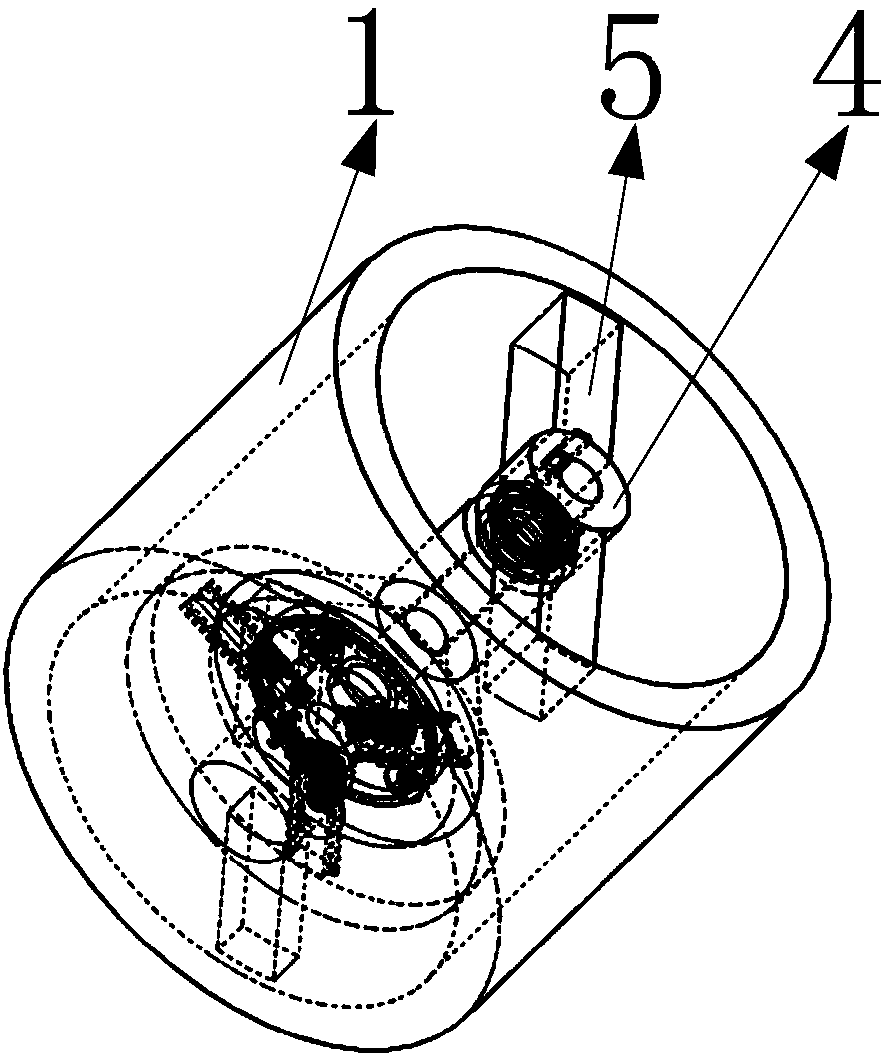

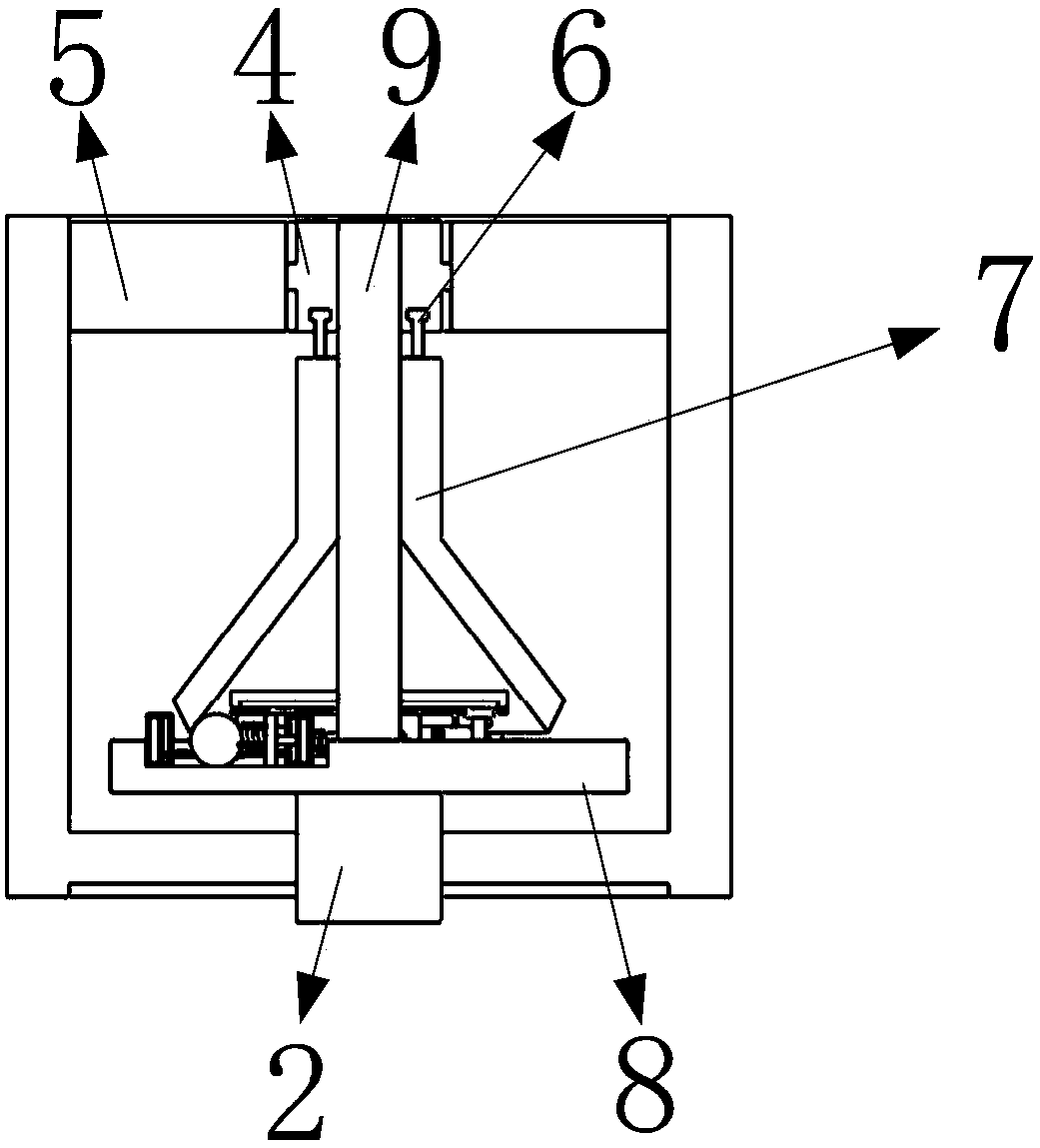

[0032] Such as figure 1 , 2 As shown, it includes a circular fixed shell 1, an input shaft 2, a first fixed column 3, a control rod 4, a second fixed column 5, a T-ring 6, a conical shell 7, a disc 8, a connecting shaft 9, a fixed Disk 10, first hydraulic cylinder 11, second hydraulic cylinder 12, third hydraulic cylinder 13, ring gear 14, guide block 15, rectangular groove 16, first ball 17, second ball 18, third ball 19, gear 20. The first fixed spring 21, the second fixed spring 22, the fixed block 23, the rack 24, the fixed plate 25, the fixed shaft 26, the fourth hydraulic cylinder 27, such as Figure 5 As shown, one end of the two first fixed columns 3 is fixedly installed on the inner circle surface of one end of the circular fixed shell 1; notches are arranged on the end faces of one end of the two second fixed columns 5; two second fixed columns 5 The end of the column 5 without a notch is fixedly installed on the inner circular surface of the circular fixed shell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com