Capacitive RF MEMS switch

A capacitive and switching technology, applied in circuits, relays, electrical components, etc., can solve the problems of short switching time, high driving voltage, low energy consumption, etc., and achieve the effect of reducing the elastic coefficient and driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The design will be further described below in conjunction with the accompanying drawings of the description.

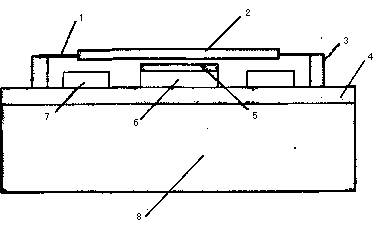

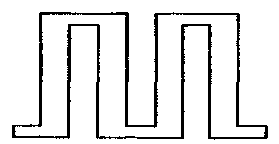

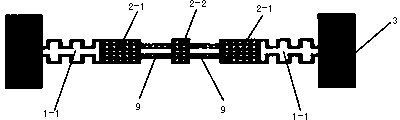

[0013] Such as figure 1 --Shown in 3, a capacitive RF MEMS switch includes a substrate 8, a buffer dielectric layer 4 on the substrate, a ground wire 7, a coplanar waveguide transmission line 6, an anchor point 3, an insulating dielectric layer 5, and an elastic fold The beam 1, the upper electrode 2, the ground wire 7, the coplanar waveguide transmission line 6, and the anchor point 3 are set on the buffer medium layer 4, the insulating medium layer 5 is covered on the coplanar waveguide transmission line 6, and the elastic One end of the folding beam 1 is connected to the anchor point 3, and the other end is connected to the upper electrode 2. There is a gap between the upper electrode 2 and the insulating medium layer 5. It is characterized in that: the bending shape of the elastic folding beam 1 is n-shaped, curved The number is 2, and the number of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com