Vertical and rotating combined pressure type multi-anvil press

A compound pressurization and vertical pressurization technology, applied in the field of high-pressure physics, can solve the problems that high-pressure devices do not have the function of rotating pressurization, and achieve the effects of less investment, fast pressure transmission and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

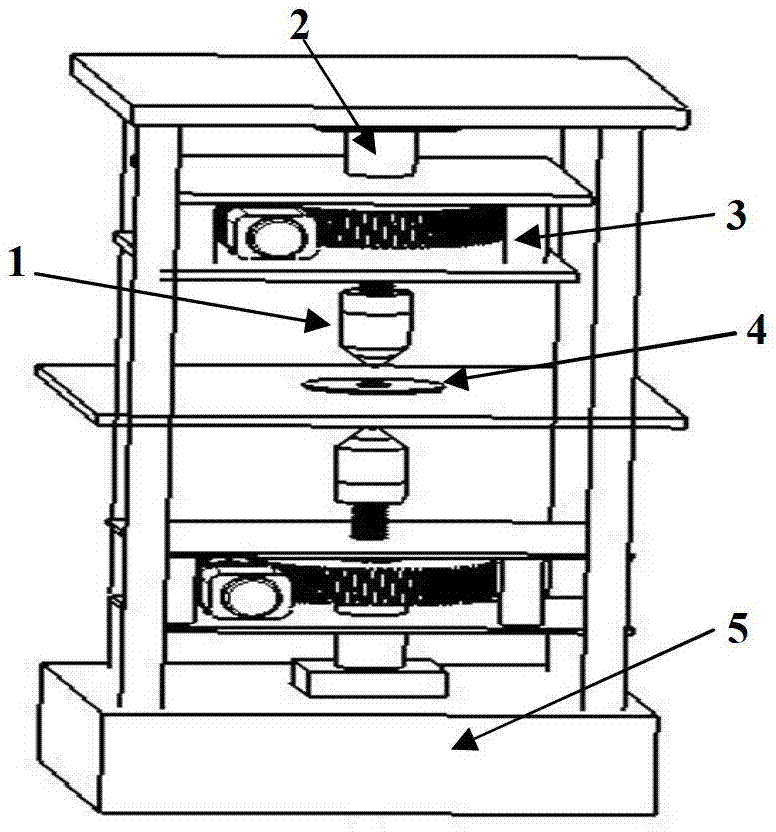

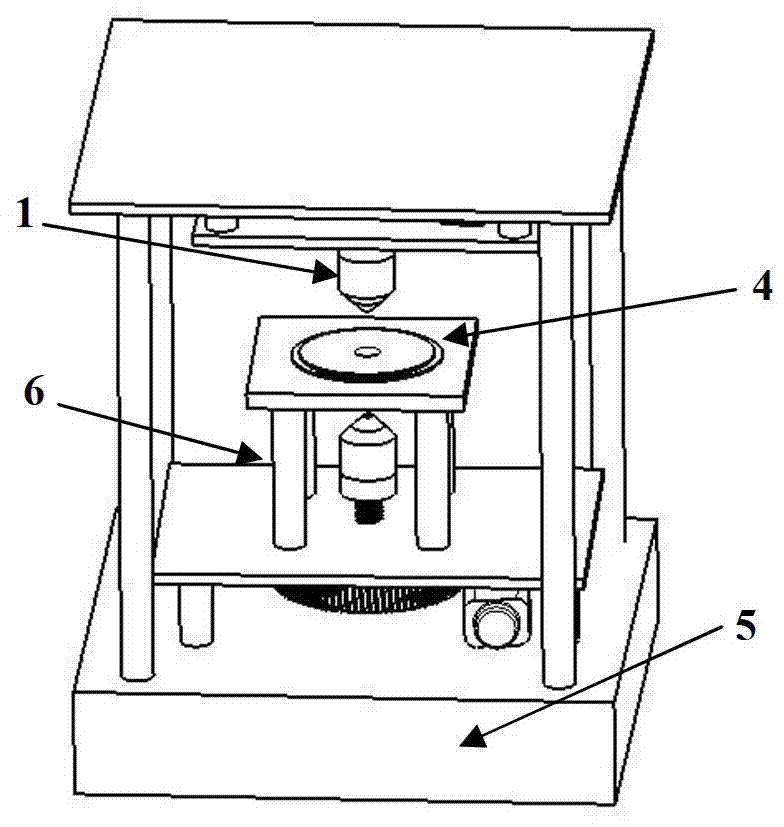

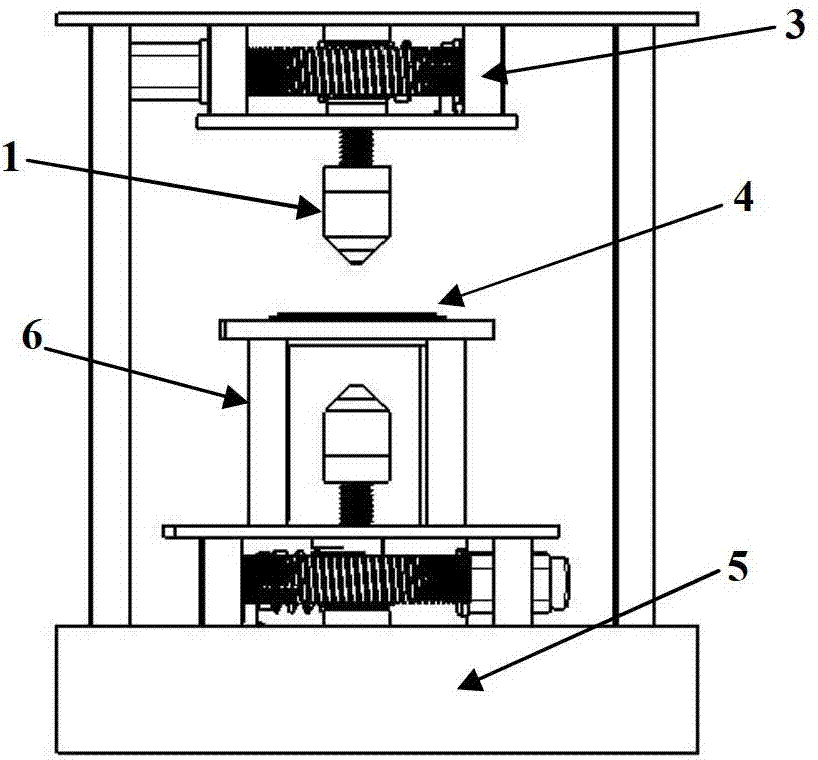

[0036] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0037] Traditional high-pressure devices do not have the function of rotary pressurization, and cannot realize the synthesis of materials under high shear force, which makes it difficult to artificially synthesize pink diamonds (diamonds), which are of great ornamental and research value; in addition, rotary pressurization The lack of functionality limits the discovery of new materials and phenomena. In order to solve the problem that the existing high-pressure device does not have the function of rotating pressurization and realize the synthesis of materials under the action of high shear force, it complements the advantages of traditional high-pressure devices to a certain extent and meets the requirements of high-pressure physics, geophysics, materials science and high-pressure biology. To meet the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com