Card-poking mechanism with pressuring function and card sender using the same

A card issuing machine and functional technology, applied in the direction of instruments, ticketing equipment, etc., can solve the problems of increasing the power of the reel, easy plastic deformation of the tension spring, and increasing the wear of the reel, so as to reduce the wear of the reel, reduce the power of the reel, and extend the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

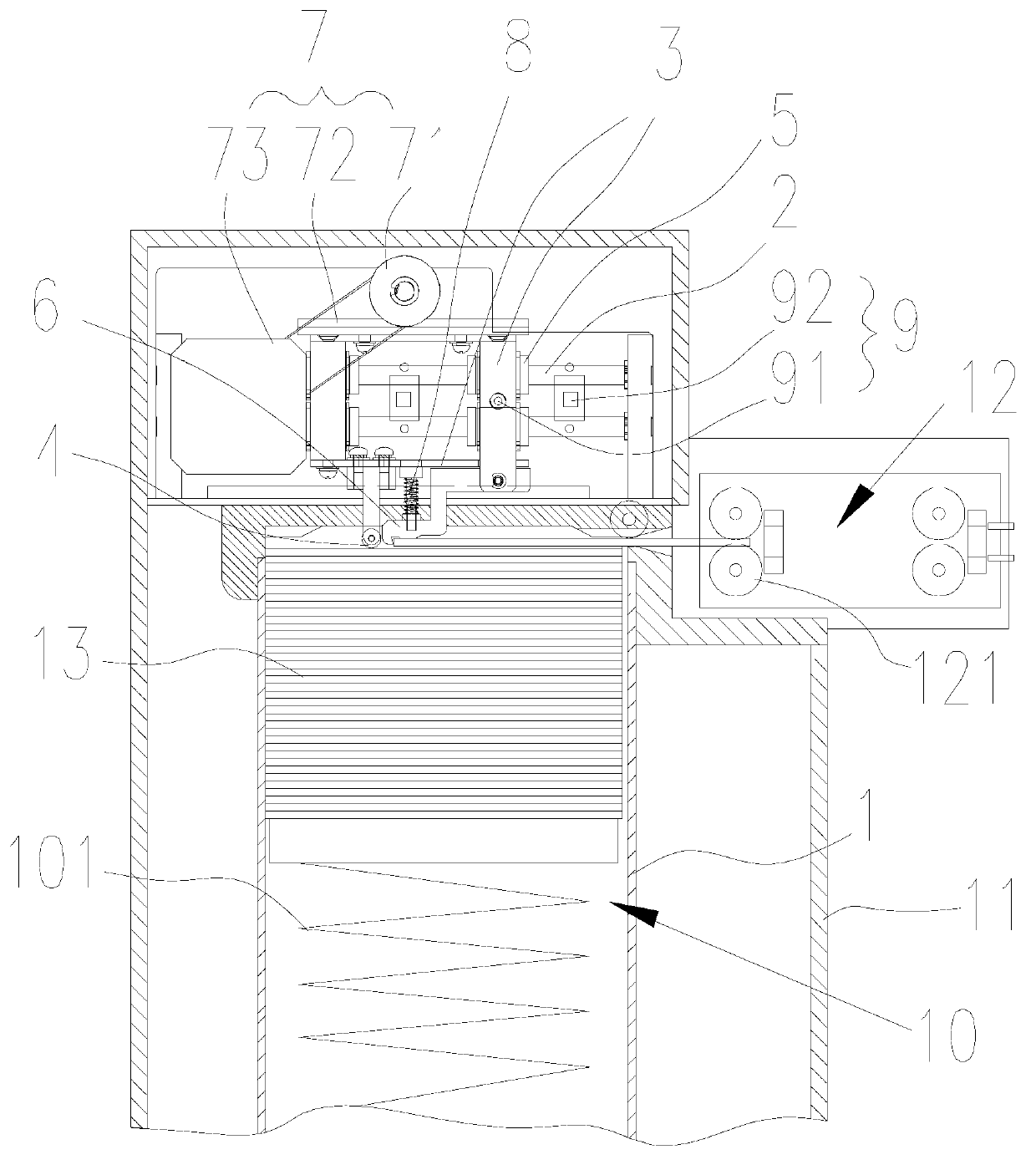

[0025] Such as figure 1 The shown card dialing mechanism with the function of applying pressure includes a guide rail 2, a slider 3, a linear reciprocating mechanism 7 and a detection device for detecting the moving position of the slider 3, all of which are installed on the card issuing machine chassis 9.

[0026] The linear reciprocating mechanism 7 of the present embodiment includes a gear 71, a rack 72 and a motor 73, the rack 72 is installed on the slider 3, the gear 71 is meshed with the rack 72, and the output shaft of the motor 73 is connected to the gear 71 through a pulley , the rotation of the motor 73 drives the gear 71 to rotate, and drives the slider 3 to perform horizontal linear reciprocating motion on the guide rail 2 .

[0027] The bottom of the slider 3 is provided with a pinch wheel 4 for pressing the next card in the card storage box 1 of the card issuer and a hook 6 for moving the first card in the card box 1 of the card issuer. The pinch wheel 4 can It...

Embodiment 2

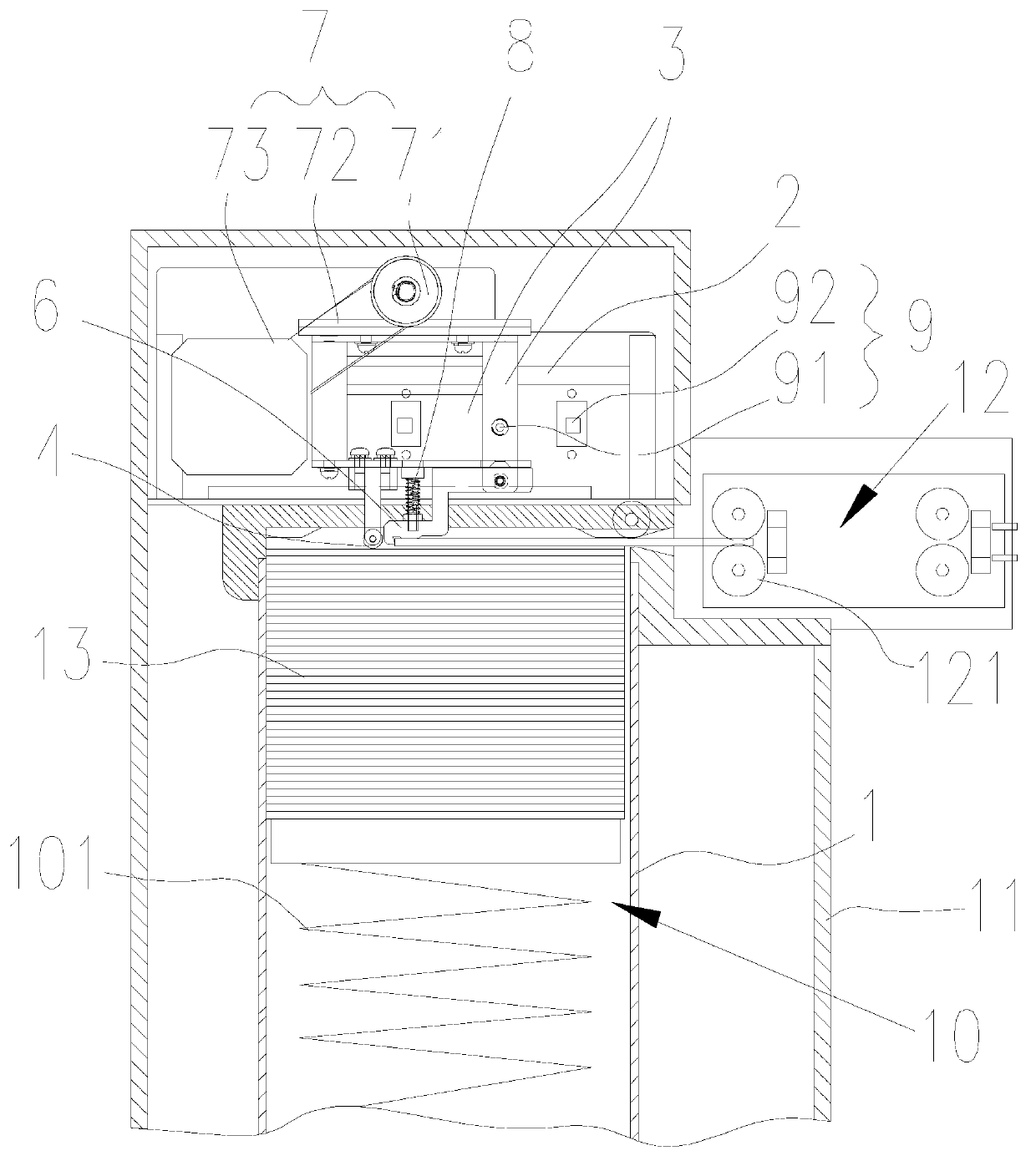

[0034] Such as figure 2 Shown is the second embodiment of the present invention, the difference between the second embodiment and the first embodiment is that the linear bearing 5 is omitted. The guide rail 2 is a linear guide rail, and a groove of the guide rail 2 is provided on the slider 3 to be slidably connected with the linear guide rail, which simplifies the structure and can also realize the linear reciprocating motion of the slider 3 .

Embodiment 3

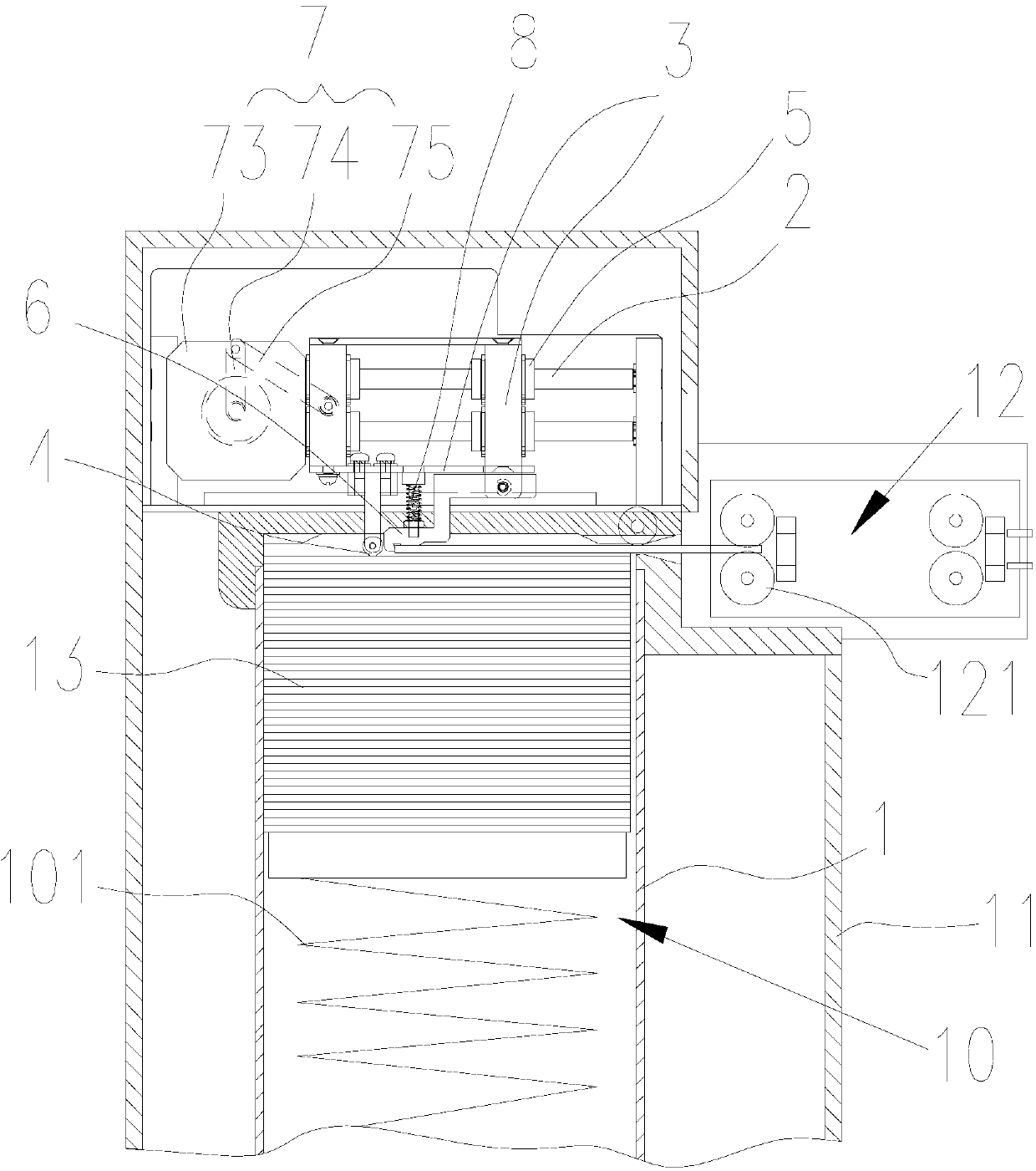

[0036] Such as image 3 Shown is the third embodiment of the present invention. The difference between the third embodiment and the first embodiment is that the detection device 9 is omitted, and the movement position of the slider 3 is limited by controlling the start and stop of the motor 73 .

[0037]Linear reciprocating mechanism 7 comprises crank 74, connecting rod 75 and motor 73, and connecting rod 75 is hinged with slide block 3, and crank 74 is installed on the output shaft of motor 73 and forms crank-rocker mechanism with connecting rod 75, and motor 73 drives crank 74 rotates to drive the connecting rod 75 to swing, and then drives the slider 3 to reciprocate linearly on the guide rail 2 through the linear bearing 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com