Numerical control proportioning hydraulic directional control valve

A hydraulic reversing valve and proportional technology, applied in the field of hydraulic reversing valve, can solve the problem of not having the functions of precise flow control and pressure control, and achieve the effect of reducing cost and failure rate, simple system and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

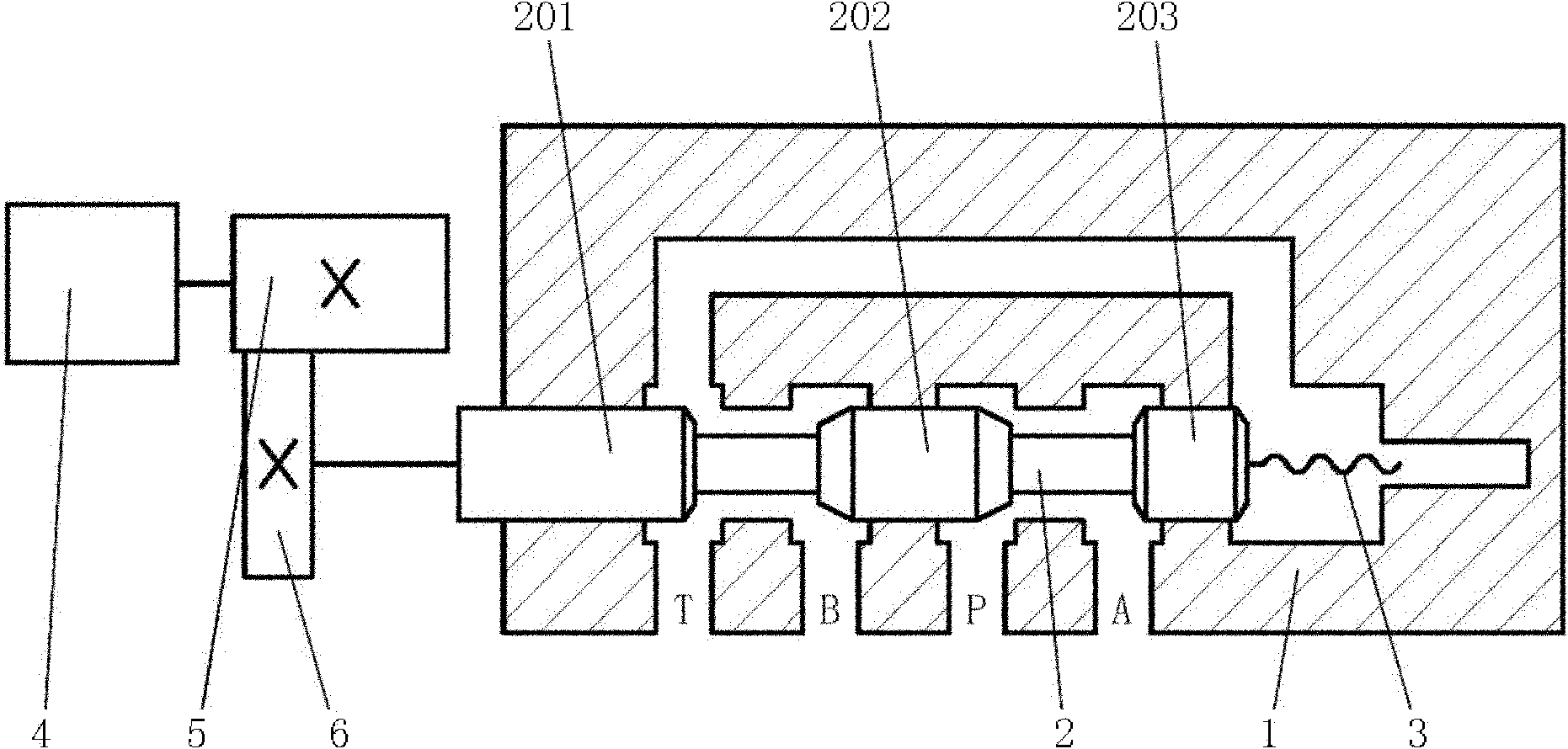

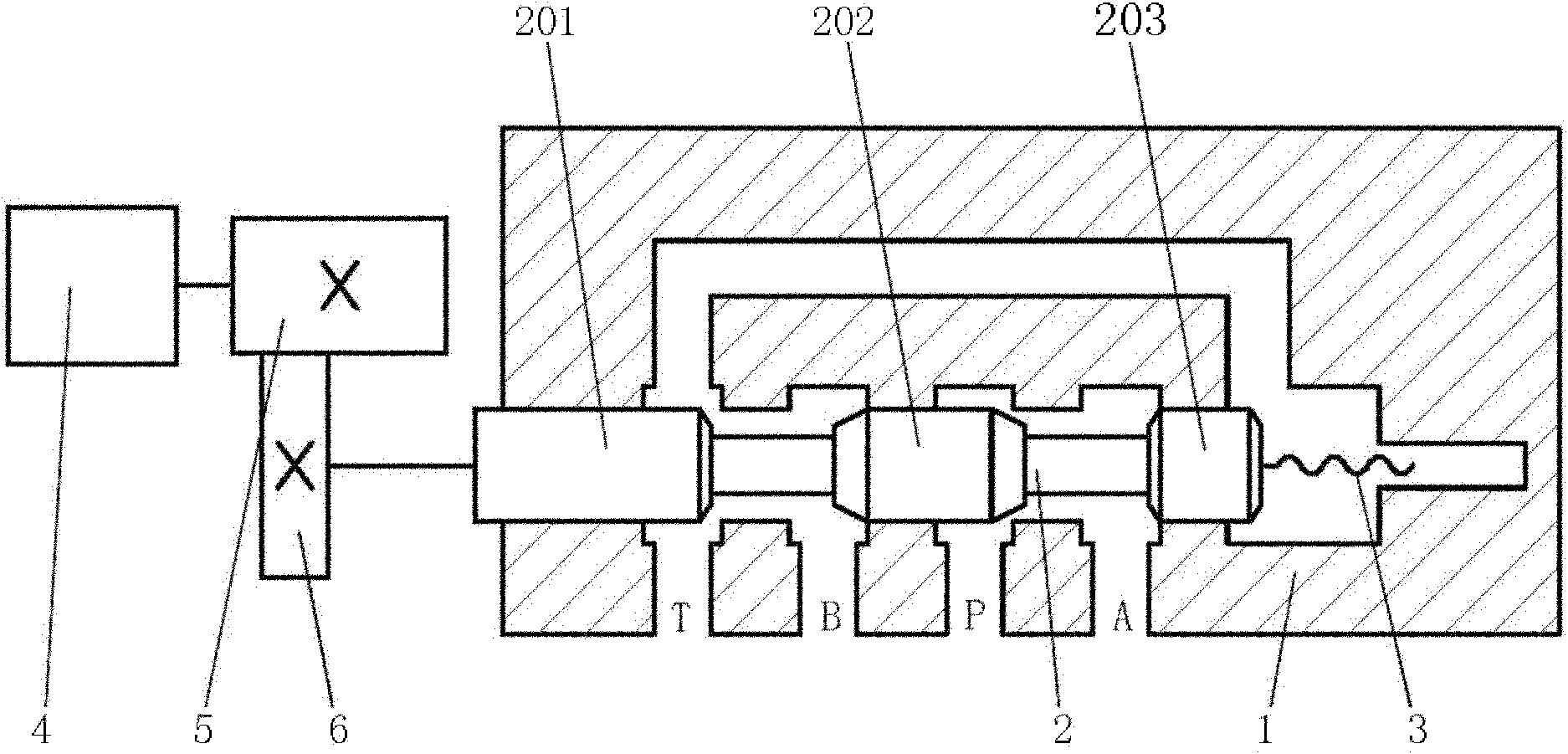

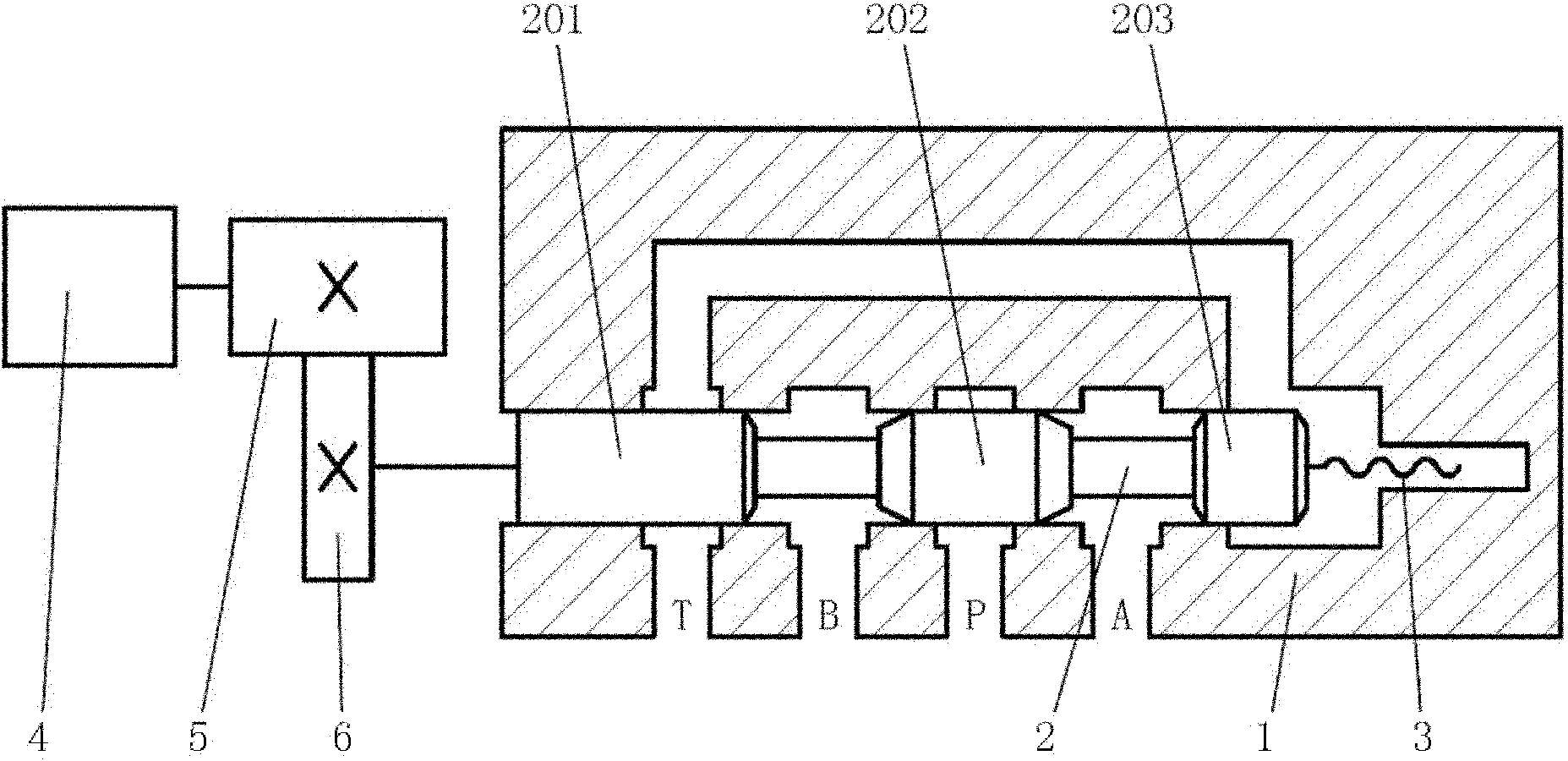

[0025] Refer to attached figure 1 to attach Figure 7 A numerically controlled proportional hydraulic reversing valve includes a valve body 1, a valve core 2, a numerically controlled motor 4 and a transmission mechanism, wherein the numerically controlled motor 4 adopts a stepping motor or a servo motor; the valve body 1 is provided with an oil inlet passage P, The first working oil passage A, the second working oil passage B, the oil return passage T, the oil inlet passage P on the valve body 1, the first working oil passage A, the second working oil passage B, the oil return passage T and the valve The valve cavity of the body 1 is connected; the valve core 2 is provided with a matching shaft 201, a matching shaft 202, and a matching shaft 3 203, wherein the longitudinal section at the two ends of the matching shaft 202 is trapezoidal, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com