Automatic control method for achieving optimal initial-pressure operation of heat-supply units

A heating unit, the best technology, applied in the direction of household heating, heating mode, heating system, etc., can solve the problems of difficult quantitative analysis, affecting the accuracy of test results, low precision, etc., to achieve low investment cost and considerable economy and environmental benefits, the effect of widespread promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments.

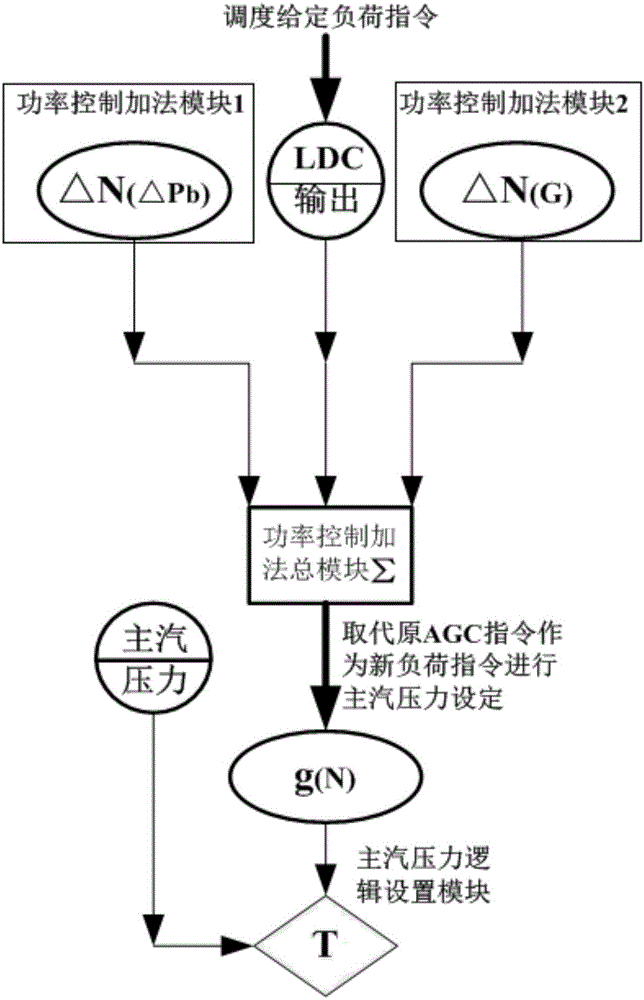

[0022] Such as figure 2 As shown, the present invention adds power control addition modules 1 and 2 to the original coordinated control system, and sets them in the main steam pressure setting value logic page. The output values of power control addition modules 1 and 2 are related to the LDC load command given value After the addition operation, it is used as a new load command to participate in the initial pressure control.

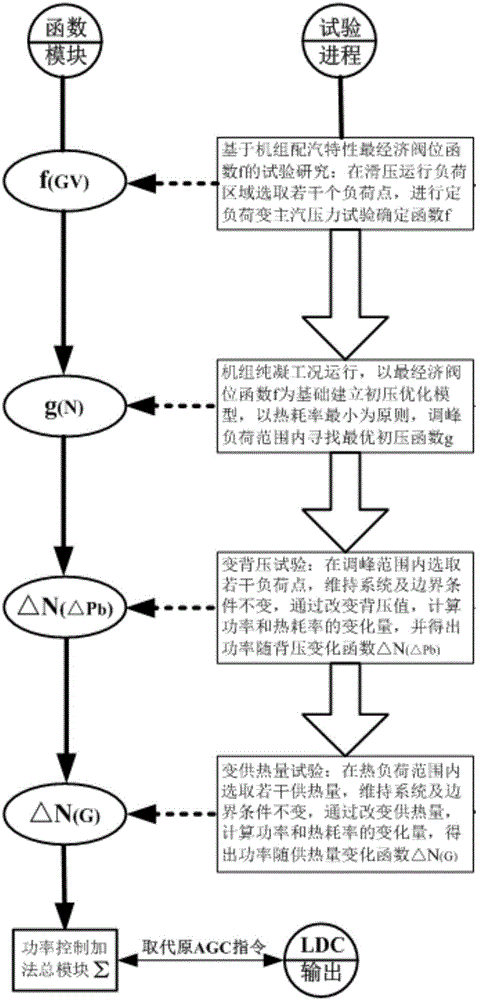

[0023] According to the requirements of ASME test standards, the condensate flow measured by the qualified ASME long-diameter flow nozzle is used as the main flow calculation basis, and the following test is carried out on the heating unit (300MW subcritical) of a certain factory. The detailed test process is as follows: figure 1 shown.

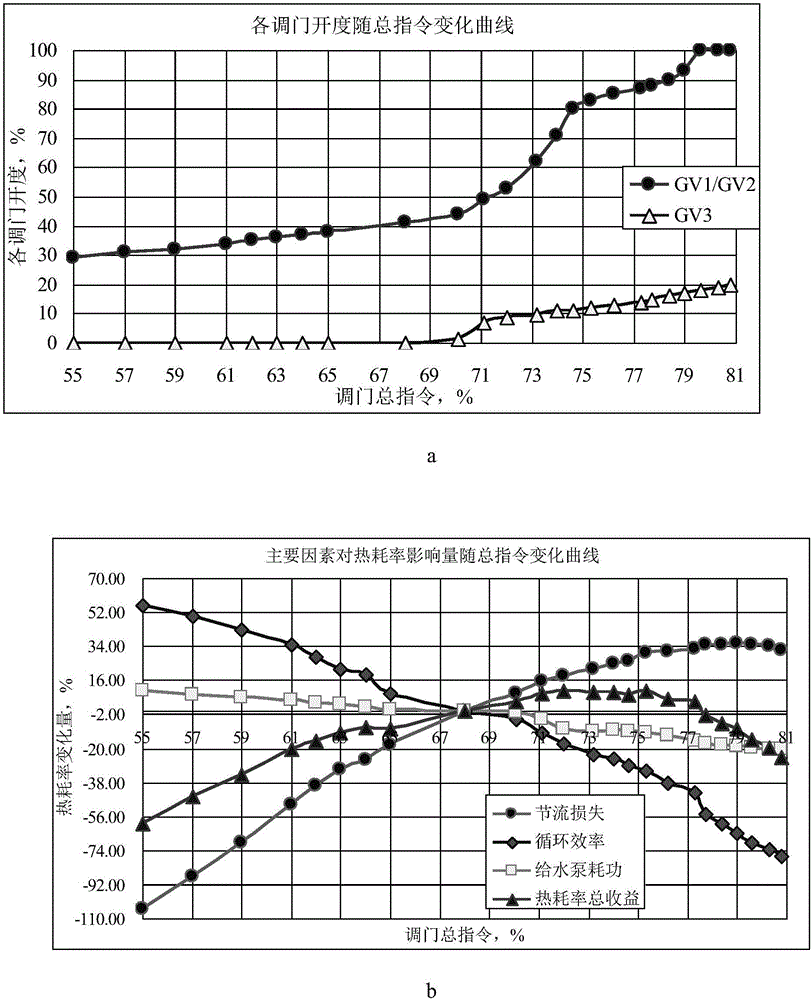

[0024] The specific test standards are: ASME PTC6.0-2004; main flow: ASME nozzles measure condensate flow;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com