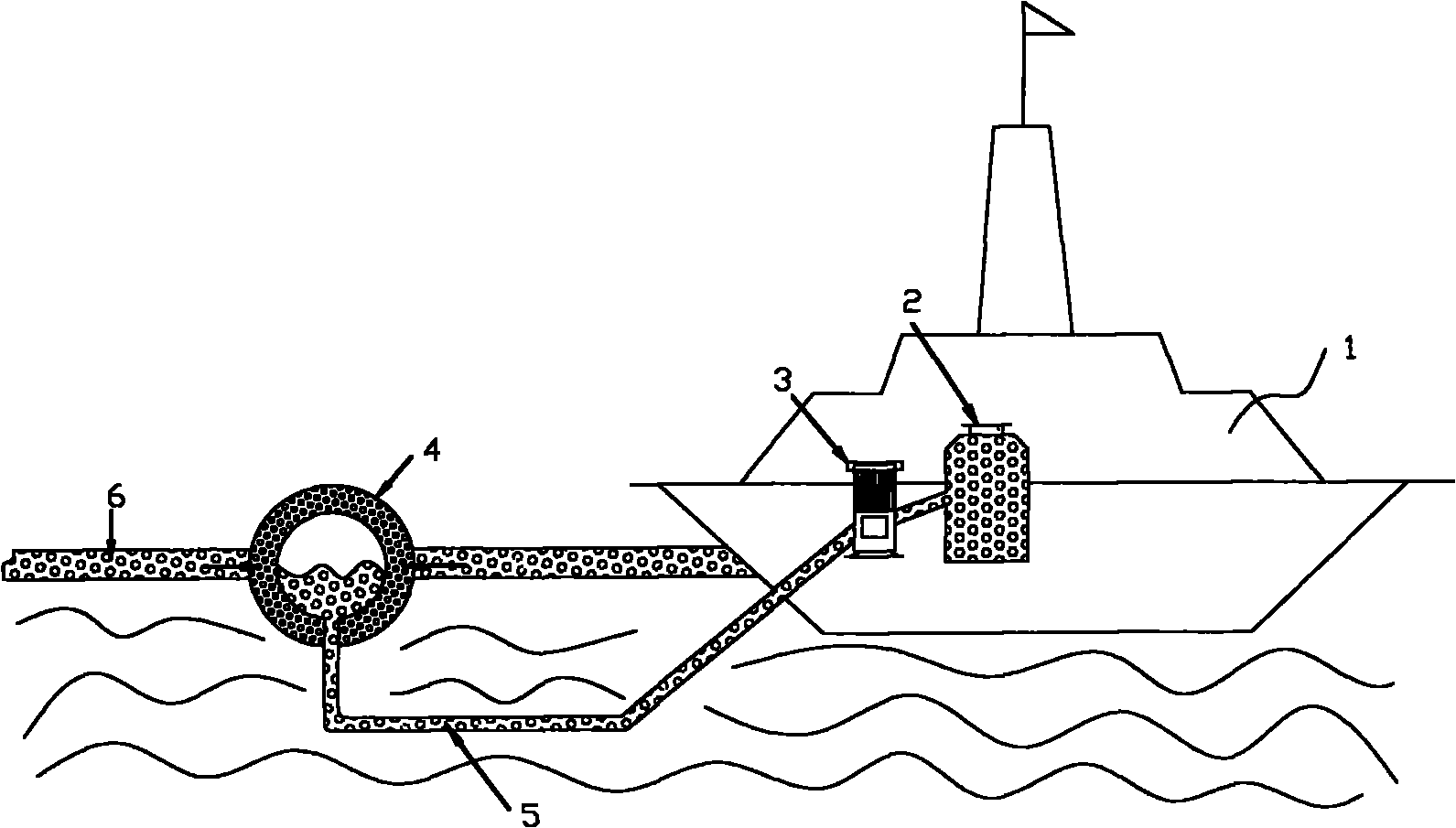

Method for collecting floating oil on water surface

A technology for oil slicks and oil slicks on water surfaces, applied in separation methods, grease/oily substances/suspton removal devices, liquid separation, etc., can solve the problems of low oil slick collection efficiency and unsuitable for large-scale oil slick collection, and achieve The effect of improving oil slick collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] Preparation of dearomatized petroleum ether: 60-100 mesh coarse-porous microsphere silica gel and 70-120 mesh neutral chromatographic alumina (activated at 150-160°C for 4 hours) were loaded by column chromatography before complete cooling into a glass column with an inner diameter of 25 mm and a height of 750 mm. The lower layer of silica gel is 600mm high and covered with 50mm thick alumina. Commercially available petroleum ether (60-90°C fraction) is passed through this column to remove aromatics. Collect petroleum ether in a narrow-mouthed bottle, and use water as a reference at 225 nm on an ultraviolet spectrophotometer to measure the light transmittance of the treated petroleum ether so that it should not be less than 80%.

[0072] standard curve drawing

[0073] Add 0, 2.00, 4.00, 8.00, 12.00, 20.00 and 25.00mL of standard oil solution to seven 50mL volumetric flasks, and dilute to the mark with petroleum ether (60-90°C). On an ultraviolet spectrophotometer, at...

preparation Embodiment 1

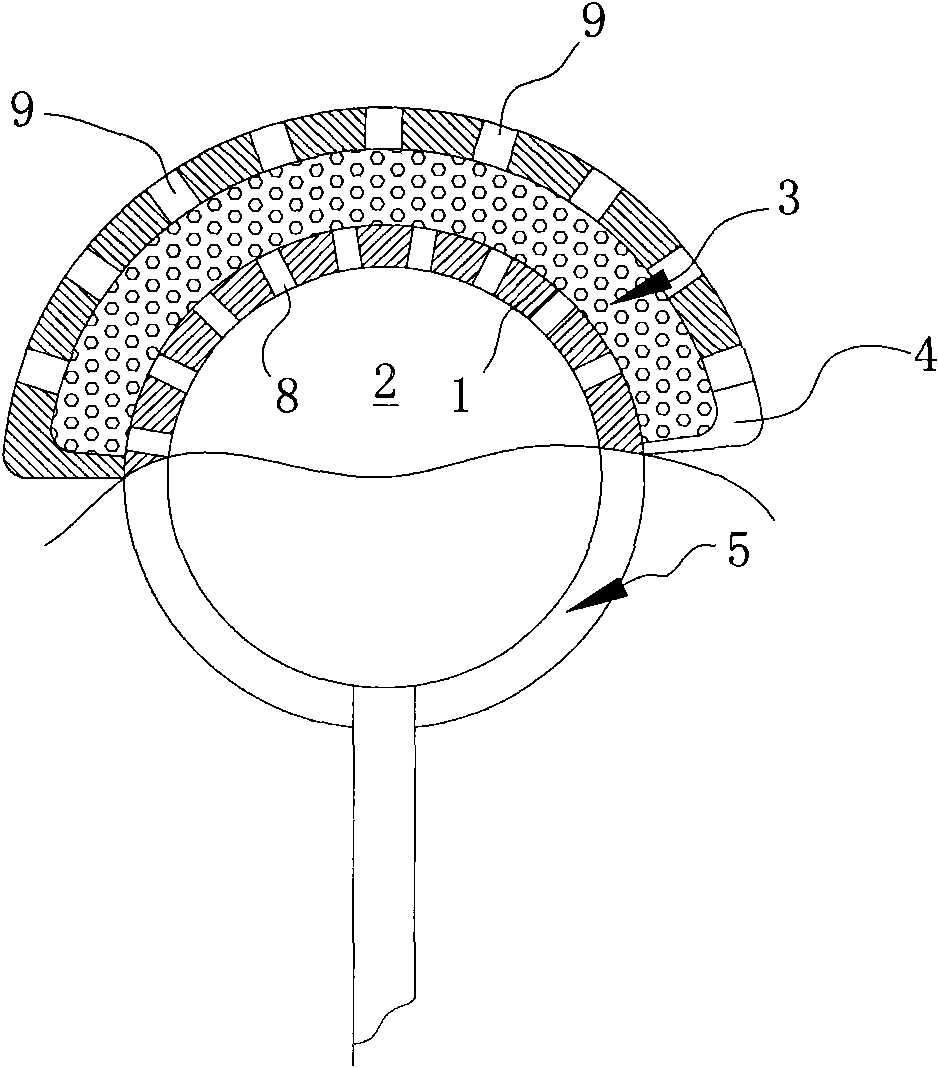

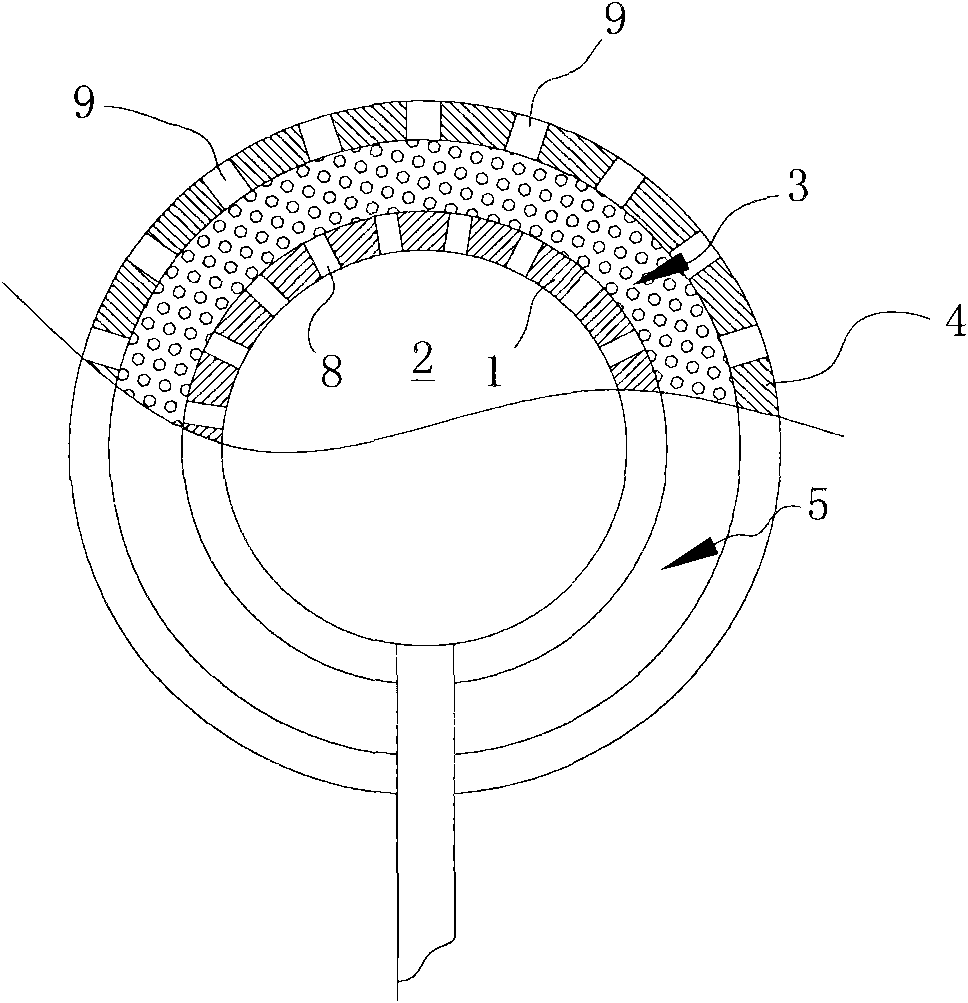

[0079] This example is used to illustrate the preparation of the coated silica sand coated with an oleophilic and hydrophobic film on the surface provided by the present invention.

[0080] Heat 3kg of quartz sand particles (density 1.65g / cm3) with an average particle diameter of 0.4mm to 250°C and put them in a sand mixer for stirring. After that, cool down to 200°C and add polyamide resin modified epoxy resin 0.15kg, fully stirred, so that the resin is evenly distributed on the outer surface of the quartz sand particles, then add aliphatic amine curing agent (the weight ratio of curing agent to resin is 2:100) to solidify, and finally cool to room temperature, crush to obtain a coating Silica sand (coating thickness 1-2 microns). The sphericity of the obtained coated silica sand is 0.72, and the particle diameter distribution is 320-450 microns.

preparation Embodiment 2

[0082] This example is used to illustrate the preparation of the coated silica sand coated with an oleophilic and hydrophobic film on the surface provided by the present invention.

[0083] Prepare coated particles according to the same method as Preparation Example 1, the difference is that a phthalate plasticizer is added before adding the curing agent, and its weight ratio to the resin is 10: 100, and fully stirred to obtain The cladding layer thickness of the coated silica sand is 2-3 microns, the sphericity is 0.75, and the particle diameter distribution is 350-430 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com