Separation method of copper-lead sulfide minerals

A beneficiation method, copper and lead technology, applied in solid separation, flotation and other directions, can solve the problems of unsuitable large-scale promotion, high production cost, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

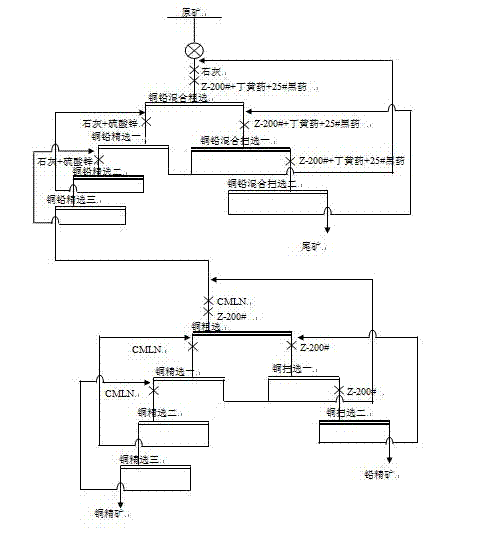

Image

Examples

Embodiment 1

[0021] The raw ore grade of copper-lead sulfide ore is Cu 0.35%, Pb 1.35%, the raw ore is ground to -74μm72%, the slurry is added to the flotation tank for copper-lead mixed flotation operation, and lime 2Kg / ton is added to the copper-lead mixed roughing operation Raw ore, Z-200#30g / ton raw ore, butyl xanthate 80g / ton raw ore, 25# black medicine 40g / ton raw ore, flotation to obtain copper-lead mixed coarse concentrate; copper-lead mixed flotation and sweeping, add Z-200# 15g / ton raw ore, dixanthate 40g / ton raw ore, 25# black medicine 20g / ton raw ore, flotation to obtain copper-lead scavenging concentrate 1; copper-lead mixed flotation and scavenging 2 add Z-200# 7g / ton raw ore, Ding xanthate 20g / ton raw ore, 25# black medicine 10g / ton raw ore, flotation to obtain copper-lead mixed sweep concentrate II.

[0022] Add 300g / ton raw ore of lime and 220g / ton raw ore of zinc sulfate in selection 1 of copper-lead mixed coarse concentrate, add 220g / ton of raw ore of zinc sulfate and 12...

Embodiment 2

[0031] The raw ore grade of copper-lead sulfide ore is Cu0.98%, Pb3.94%, the raw ore is ground to -74μm75%, the slurry is added to the flotation tank for copper-lead mixed flotation operation, and 1.5Kg of lime is added to the copper-lead mixed roughing operation / ton raw ore, Z-200#30g / ton raw ore, butyroxanthate 120g / ton raw ore, 25# black medicine 35g / ton raw ore, flotation to obtain copper-lead mixed coarse concentrate; copper-lead mixed scavenging and adding Z-200 #15g / ton raw ore, butyl xanthate 55g / ton raw ore, 25# black medicine 20g / ton raw ore, flotation to obtain copper-lead scavenging concentrate 1; copper-lead mixed scavenging 2 Add Z-200#10g / ton raw ore, Ding xanthate 35g / ton raw ore, 25# black medicine 10g / ton raw ore, flotation to obtain copper-lead mixed sweeping concentrate II.

[0032] Add 290g / ton raw ore of lime and 180g / ton raw ore of zinc sulfate in the selection 1 of copper-lead mixed coarse concentrate; Mixed concentrates.

[0033] Copper-lead mixed ...

Embodiment 3

[0041]The raw ore grade of copper-lead sulfide ore is Cu0.91%, Pb1.03%, the raw ore is ground to -74μm75%, the slurry is added to the flotation tank for copper-lead mixed flotation operation, and 3.2Kg of lime is added to the copper-lead mixed roughing operation / ton raw ore, Z-200#33g / ton raw ore, butyl xanthate 60g / ton raw ore, 25# black medicine 30g / ton raw ore, flotation to obtain copper-lead mixed coarse concentrate; 200# 10g / ton raw ore, butyl xanthate 20g / ton raw ore, 25# black medicine 10g / ton raw ore, flotation to obtain copper-lead scavenging concentrate 1; copper-lead mixed flotation scavenging 2 is added to Z-200# 7g / ton Raw ore, butyl xanthate 10g / ton raw ore, 25# black medicine 5g / ton raw ore, flotation to obtain copper-lead mixed scavenging concentrate II.

[0042] Copper-lead mixed coarse concentrate selection 1 adds lime 370g / ton raw ore, zinc sulfate 260 / ton, selection 2 adds lime 180g / ton raw ore, zinc sulfate 100g / ton raw ore, selection 3 blank selection to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com