Preparation method of oil-water separation omentum with underwater ultra oleophobicity

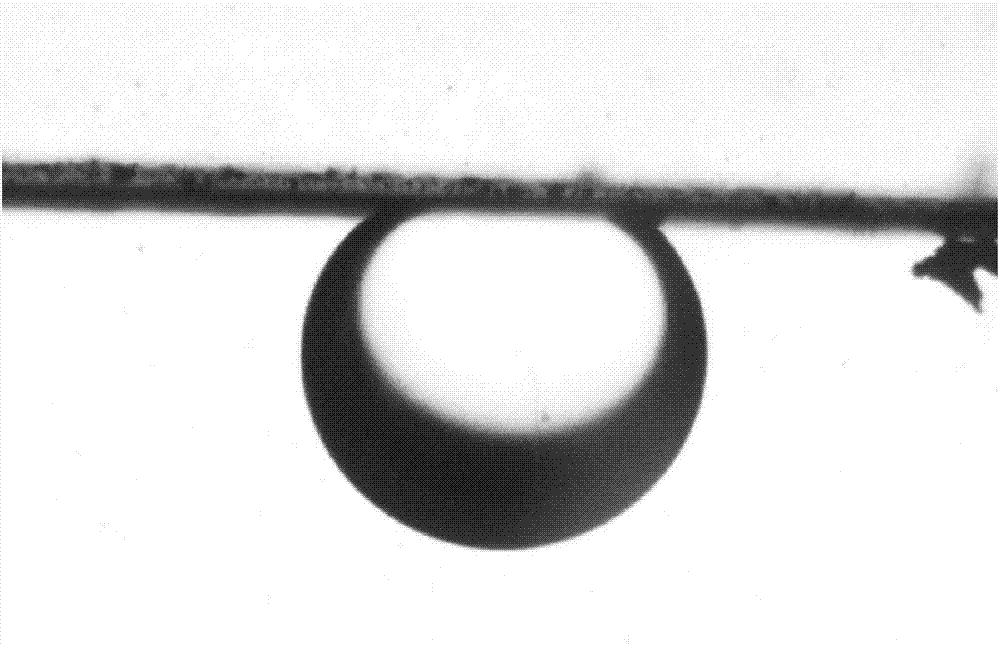

An oil-water separation omentum membrane, underwater superoleophobic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc. Repeated use and other problems, to achieve the effect of fast oil-water separation, enhanced hydrophilicity, simple equipment and manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) immerse a 1000-mesh (15-micron aperture) stainless steel mesh (20 cm × 20 cm) in acetone, isopropanol and deionized water for 10 minutes, and then dry it at room temperature;

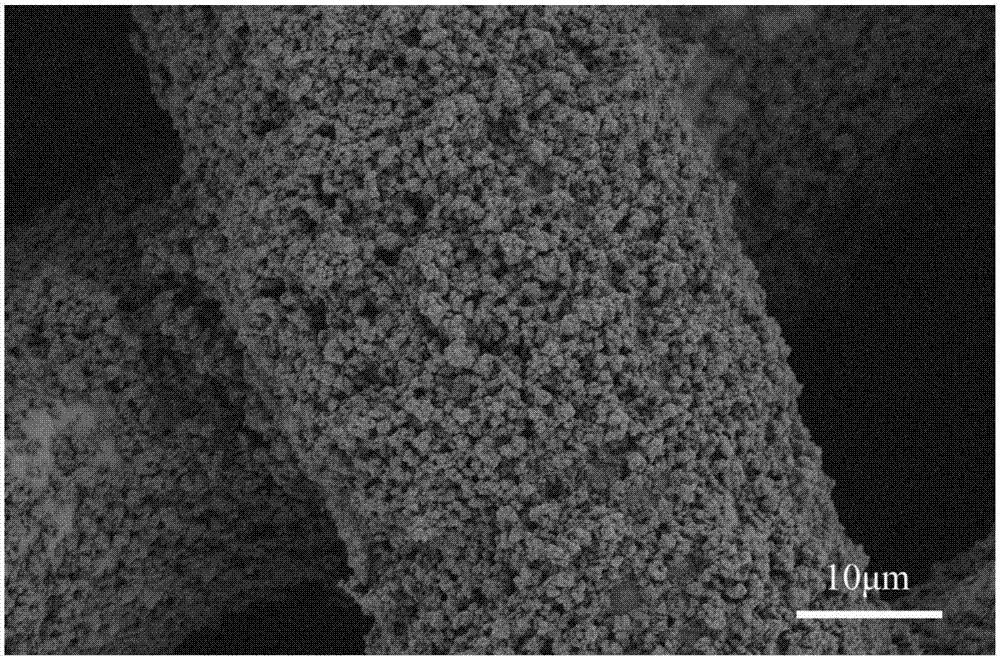

[0033] (2) At room temperature, add 25ml of water, 6.5g of acrylamide, 1g of titanium dioxide (28 nanometers in particle size), 0.35g of N, N'-methylenebisacrylamide, 0.15g of polyacrylamide and 0.18 g of 2,2-diethoxyacetophenone, magnetically stirred and mixed uniformly to obtain a mixed solution;

[0034] (3) uniformly coating the mixed solution obtained in step (2) on the surface of the stainless steel mesh after step (1) is dried;

[0035] (4) With a wavelength of 365nm and an optical energy density of 1350mJ / cm 2 , the irradiation distance is 20cm ultraviolet light source irradiation step (3) the stainless steel net coated with the mixed solution for 95 minutes, so that the acrylamide monomer and N, N'-methylenebisacrylamide cross-linking agent in the initiator 2, 2 -Cross-linked polym...

Embodiment 2

[0039] (1) immerse a 800-mesh (19 micron aperture) copper grid (20 cm × 20 cm) in acetone, isopropanol and deionized water for 10 minutes, and then dry it at room temperature;

[0040] (2) At room temperature, add 25ml of water, 5.7g of acrylic acid, 1g of zinc oxide (25nm in particle size), 0.5g of silicon dioxide (38nm in particle size), N,N'-methylene 0.15g of bisacrylamide, 0.17g of polyvinyl alcohol and 0.15g of 2,2-diethoxyacetophenone were mixed evenly by magnetic stirring to obtain a mixed solution;

[0041] (3) uniformly coating the mixed solution obtained in step (2) on the surface of the copper mesh after step (1) dries;

[0042] (4) With a wavelength of 365nm and an optical energy density of 1300mJ / cm 2 , the irradiation distance is 5cm UV light source irradiation step (3) Copper mesh coated with the mixed solution for 85 minutes, so that the acrylic acid monomer and N, N'-methylenebisacrylamide crosslinking agent in the initiator 2, 2- Under the action of dietho...

Embodiment 3

[0046] (1) A 400-mesh nylon mesh (20 cm x 20 cm) was immersed in acetone, isopropanol and deionized water for 10 minutes, and then dried at room temperature;

[0047] (2) At room temperature, add 25ml of water, 15g of N-ethylacrylamide, 1g of zinc oxide (58nm in particle size), 0.5g of calcium carbonate (29nm in particle size), and 0.5g of silicon dioxide in a 50ml Erlenmeyer flask at room temperature (particle size 68 nanometers), N, N'-methylenebisacrylamide 0.25g, polyvinylpyrrolidone 0.16g and 2,2-diethoxyacetophenone 0.3g, magnetically stirred and mixed uniformly to obtain a mixed solution;

[0048] (3) uniformly coating the mixed solution obtained in step (2) on the surface of the nylon mesh after step (1) is dried;

[0049] (4) With a wavelength of 365nm and an optical energy density of 1200mJ / cm 2 , the irradiation distance is 15cm ultraviolet light source irradiation step (3) the nylon net coated with the mixed solution for 100 minutes, so that the N-ethylacrylamide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com