Method for separating glycol from butanediol

A separation method and technology for butanediol, applied in the field of separation of ethylene glycol and butanediol, can solve the problems of high energy consumption, complex process and high separation energy consumption, and achieve low energy consumption, simple process and simple separation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

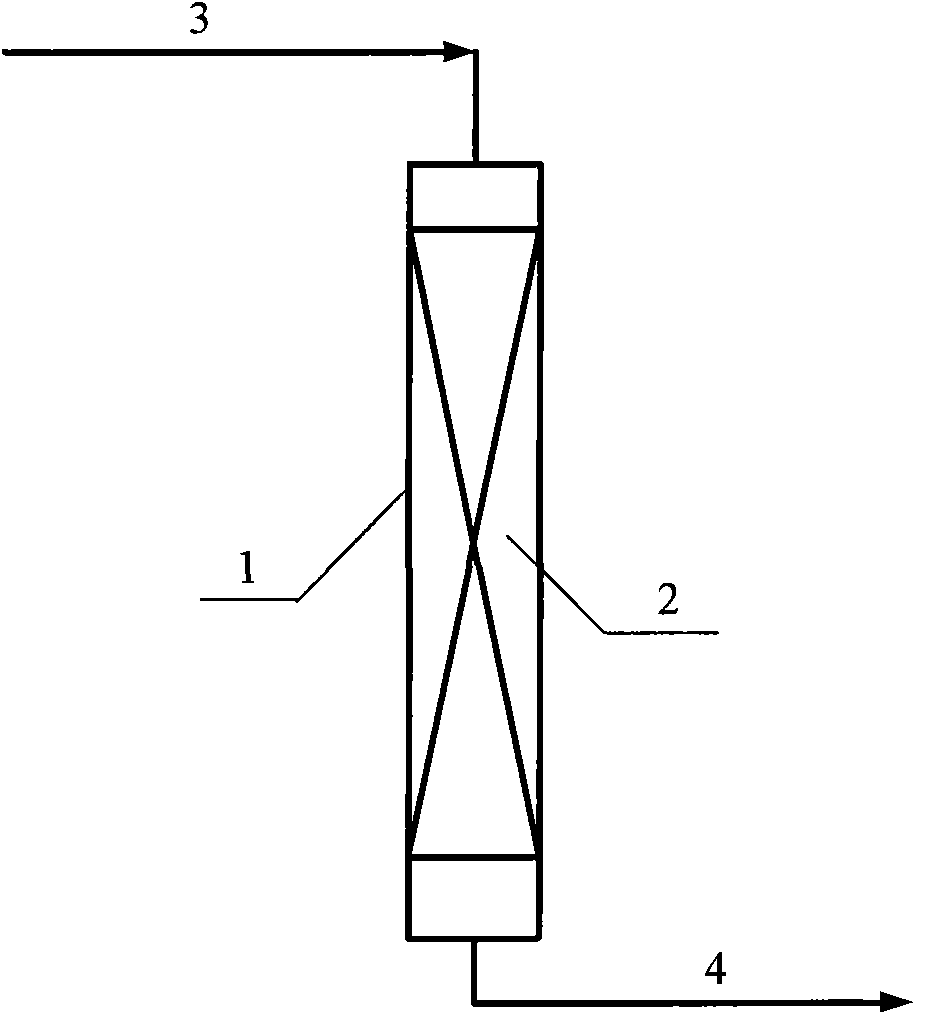

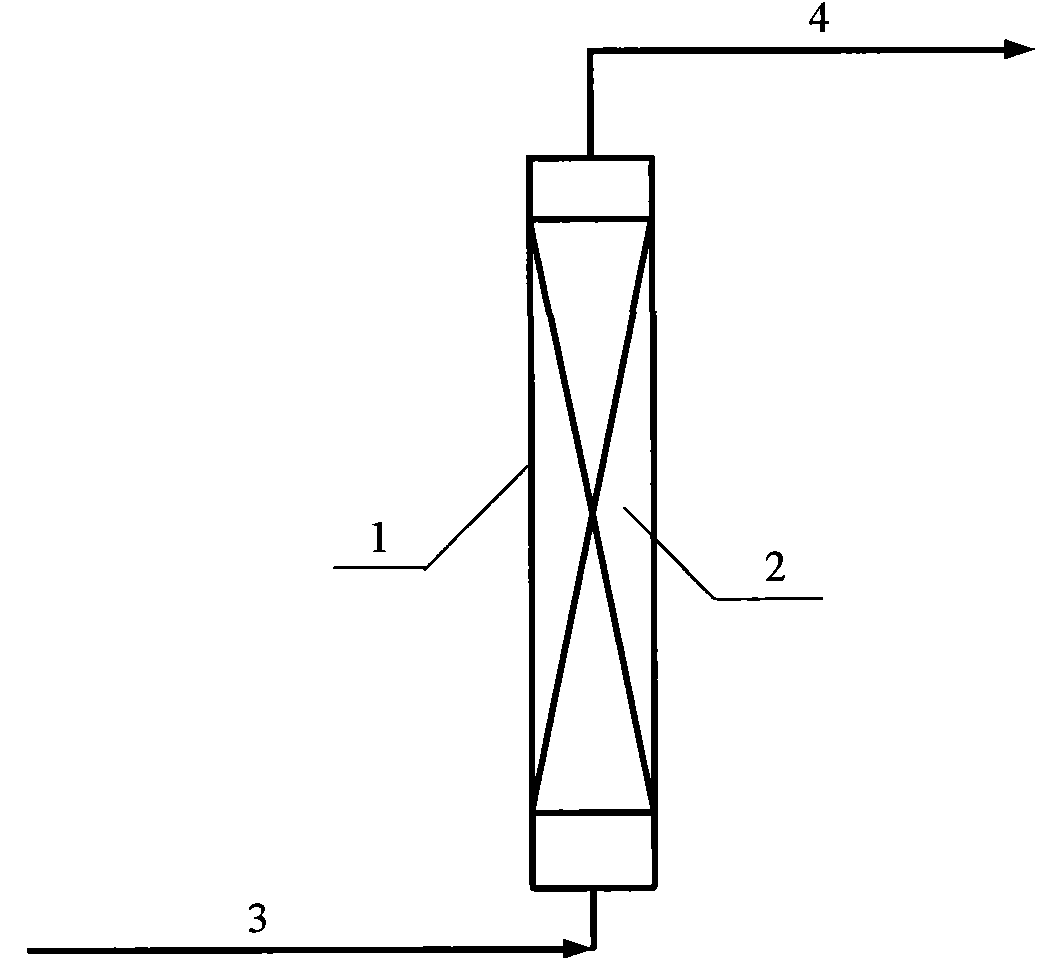

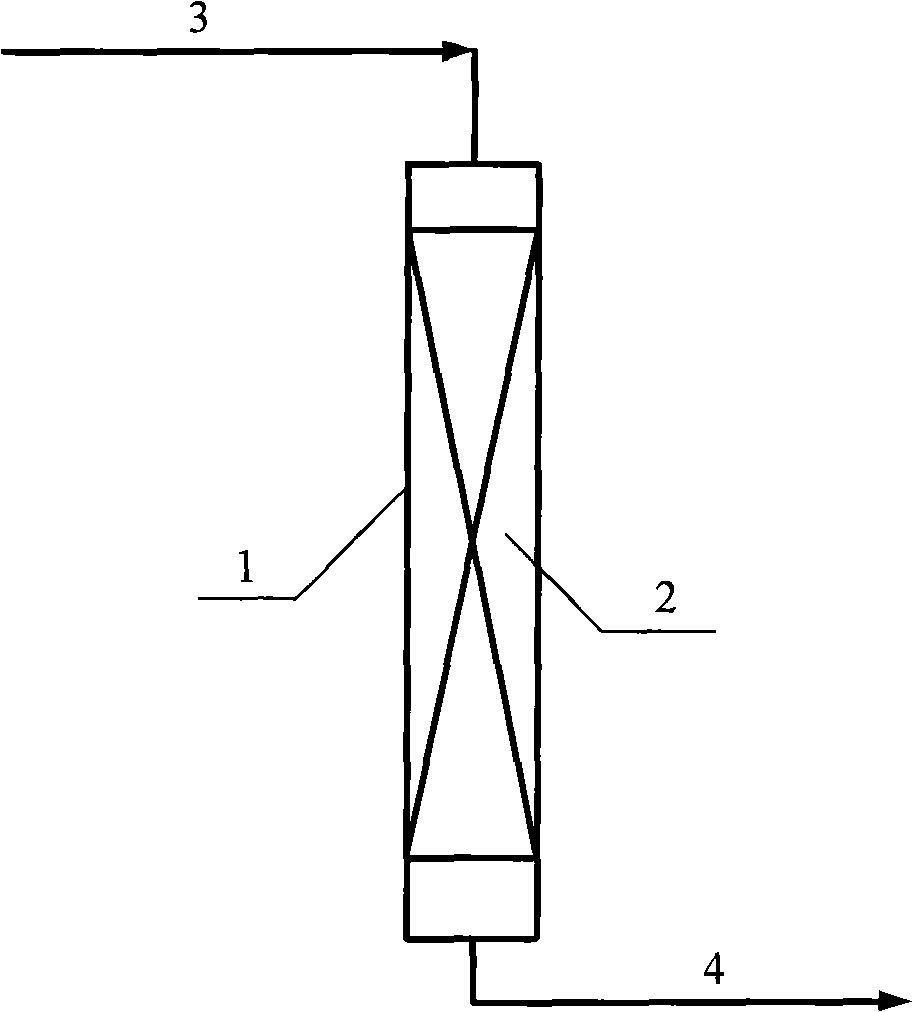

[0017] according to figure 1 Shown flow process, the ethylene glycol solution containing 1,2-butanediol (the mass content of 1,2-butanediol is 1.00%) is that 15 millimeters, height are 150 millimeters with the flow rate of 5 g / min The top of the adsorption column enters, and the adsorption column is filled with Suqing brand DA201-C resin, the operating pressure is normal pressure, the temperature is 40 ° C, and the mass fraction of ethylene glycol obtained at the bottom of the column is 99.99%.

Embodiment 2

[0019] according to figure 1 Shown flow process, the ethylene glycol solution containing 1,2-butanediol (the mass content of 1,2-butanediol is 0.10%) is 15 millimeters from inside diameter, height is 100 millimeters with the flow rate of 5 g / min The top of the adsorption column enters, and the adsorption column is filled with Suqing brand DA201-A resin, the operating pressure is 1MPa, the temperature is 20°C, and the mass fraction of ethylene glycol obtained at the bottom of the column is 100.00%.

Embodiment 3

[0021] according to figure 1 Shown flow process, the ethylene glycol solution containing 1,2-butanediol (the mass content of 1,2-butanediol is 3.00%) is 15 millimeters from inner diameter, height is 200 millimeters with the flow rate of 5 g / min The top of the adsorption column enters, and the adsorption column is filled with Suqing brand DA201-D resin, the operating pressure is 0.5MPa, the temperature is 80°C, and the mass fraction of ethylene glycol obtained at the bottom of the column is 99.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com