Transparent wear-resistant super-hydrophobic coating material, preparation method and coating process thereof

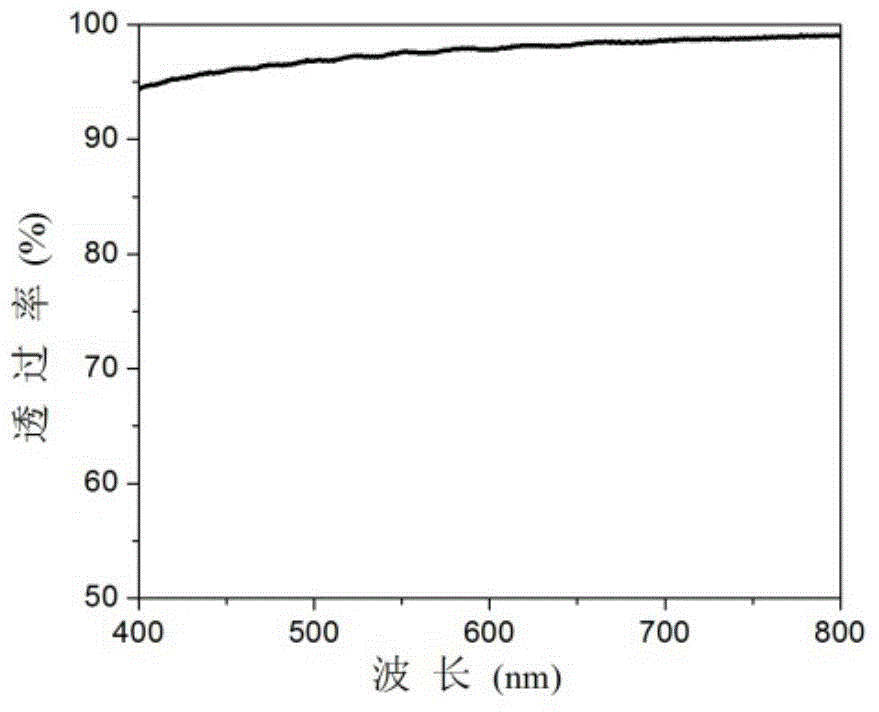

A technology of super-hydrophobic coating and coating process, which is applied in the direction of polyester coating, epoxy resin coating, polyurea/polyurethane coating, etc., and can solve the problems of large-scale preparation and commercial application of transparent super-hydrophobic surface, and achieve Effects of enhancing wear resistance, improving durability, and enhancing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

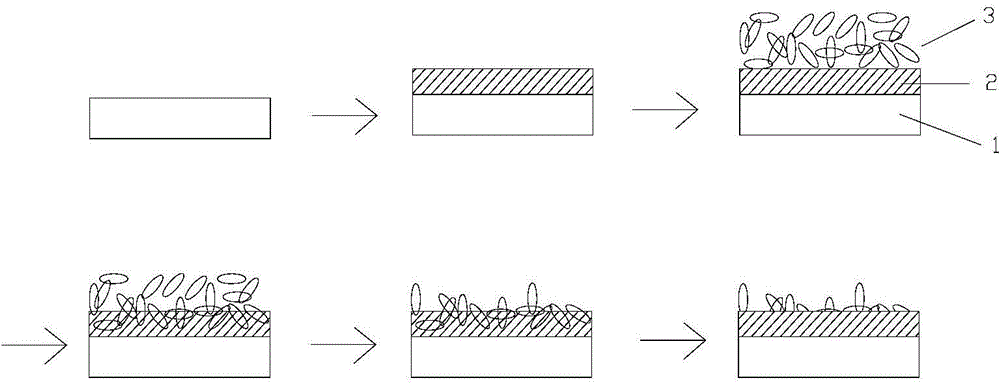

Method used

Image

Examples

Embodiment 1

[0033] Paint preparation:

[0034] Add 0.5g Degussa Aerosil-R972 hydrophobic fumed silica (particle size: 20-100nm) to 500mL ethanol solution, stir evenly, put it into an ultrasonic cleaner (power 600W) and ultrasonically treat it for 10min to obtain nanomaterial dispersion liquid;

[0035] Under mechanical stirring (rotating speed 300 rpm), 50g elastic polyurethane colloidal particles Mix with a mixed solution of 300mL acetone and 200mL xylene and stir for 30min to obtain a binder material dispersion.

[0036] The transparent wear-resistant super-hydrophobic coating includes a nanometer material dispersion and a bonding material dispersion.

[0037] Coating process:

[0038] Clean the glass plate with pure water, spray the prepared bonding material dispersion on the glass plate (15*15cm 2 , thickness 15mm), the thickness is controlled at 0.5 μm, and then it is placed in a fume hood to dry for 30 minutes. After the drying is completed, the distance from the glass plate is...

Embodiment 2

[0041] Paint preparation:

[0042] Add 50g of Jibisheng HL-150 hydrophobic fumed silica (particle size: 20-100nm) to 500mL of isopropanol solution, stir evenly, put it into an ultrasonic cleaner (power 600W) for 90 minutes of ultrasonic treatment, and obtain nanomaterials Dispersions;

[0043] Under mechanical stirring (rotating speed 300 rpm), 50g elastic polyurethane After stirring with 500 mL of acetone solution for 30 min, 5 g of polypropylene (with a particle size of 100 μm) was added thereto, and the stirring was continued for 0.5 h to obtain a binder material dispersion.

[0044] The transparent wear-resistant super-hydrophobic coating includes a nanometer material dispersion and a bonding material dispersion.

[0045] Coating process:

[0046] Clean the glass plate with pure water, spray the prepared bonding material dispersion on the glass plate (15*15cm 2 , thickness 15mm), the thickness is controlled at 5 μm, and then it is placed in a fume hood to dry for 60 min...

Embodiment 3

[0049] Paint preparation:

[0050] Add 20g of hydrophobic nano-silica aerosol powder (particle size: 20-100nm) to 500mL ethanol solution, stir evenly, put it into an ultrasonic cleaner (power 600W) for ultrasonic treatment for 60min, then add 5g of chain nano-silica aerosol powder Silicon, put it into an ultrasonic cleaner (power 600W) and ultrasonically treat it for 1h to obtain a nanomaterial dispersion;

[0051] Under mechanical stirring (300 rpm) and a constant temperature water bath at 50°C, stir 25g of French Arkema 28-800EVA and 500mL of xylene solution for 90min to obtain a binder material dispersion.

[0052] The transparent wear-resistant super-hydrophobic coating includes a nanometer material dispersion and a bonding material dispersion.

[0053] Coating process:

[0054] Clean the cement board with lye, brush the prepared bonding material dispersion on the cement board (24*12cm 2 , thickness 25mm), the thickness is controlled at 10 μm, and then it is placed in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

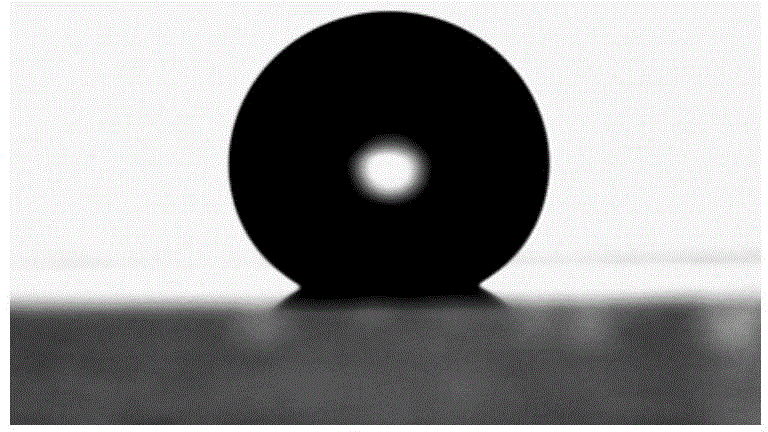

| Static contact angle | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com