Controlled releasing microcapsule for scale prevention, wax prevention or viscosity reduction of oil well

A slow-release microcapsule and anti-wax technology, which is applied in wellbore/well components, drilling compositions, earth-moving drilling, etc., can solve the problem of high crude oil extraction cost, high labor intensity, large investment in dosing equipment, etc. problems, to achieve the effect of maintaining the overall shape, reducing labor intensity, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

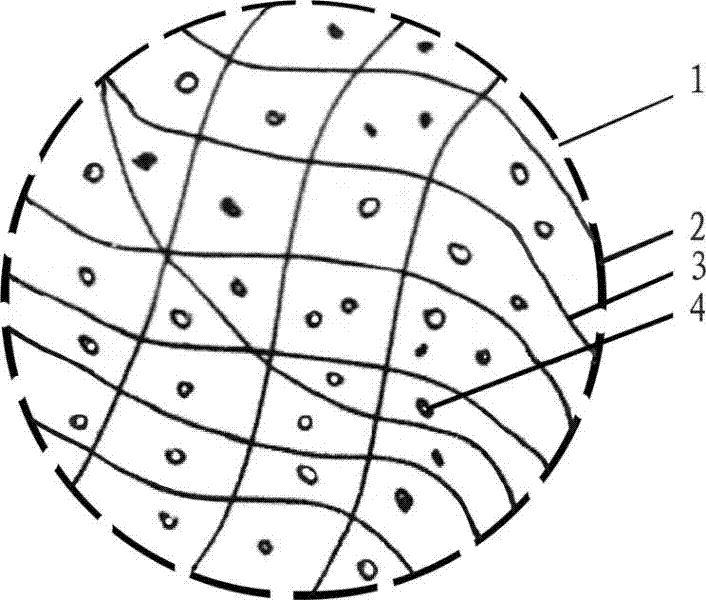

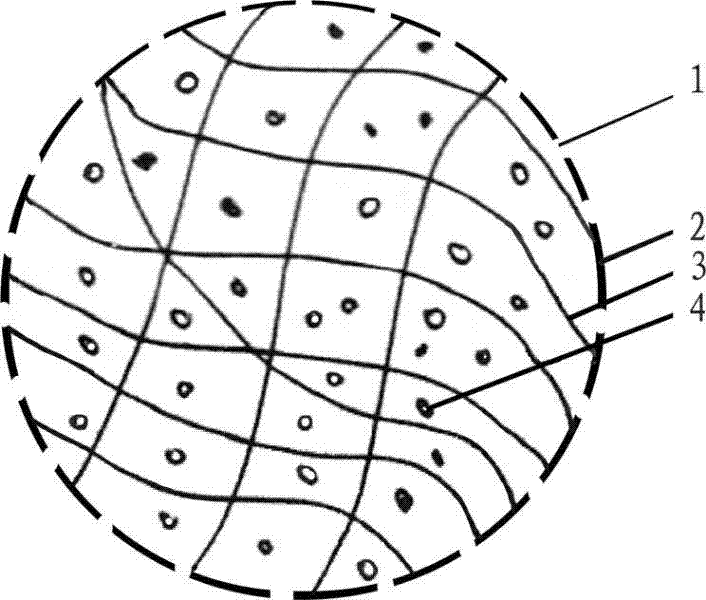

[0032] Such as figure 1 as shown, figure 1 It is a structural representation of the present invention. The invention is a slow-release microcapsule used for oil well scale prevention, wax prevention or viscosity reduction.

[0033] The sustained-release microcapsule is supported by an inorganic skeleton 3 inside, so that the density of the drug component 4 is greater than 1.0 g / cm3. It can not only maintain the overall shape of the capsule, but also not hinder the release of the pharmaceutical ingredients. The inorganic framework 3 proppant can use most of the inorganic materials that can meet the strength required by the present invention and can play the role of wax prevention, dispersion and corrosion inhibition. The inorganic skeleton components can be composed of zinc chloride, sodium silicate, sodium carbonate, sodium molybdate, sodium tripolyphosphate, sodium hexametaphosphate, etc.

[0034] The volume and shape of the present invention are solid cylindrical particl...

Embodiment 2

[0063] A slow-release microcapsule used for oil well anti-scaling, anti-wax or viscosity reduction is filled with a cross-mixed structure composed of an inorganic skeleton 3 and a pharmaceutical component 4 in a polymer composite film 2 with a surface mesh 1 things.

[0064] The volume and shape of the present invention are solid cylindrical particles with a diameter of 7mm and a height of 13mm. The addition of the inorganic skeleton 3 can maintain the shape, so that the density of the pharmaceutical component 4 is 1.3g / cm3.

[0065] A slow-release microcapsule for oil well anti-scaling, anti-wax or viscosity reduction is used as a slow-release microcapsule for oil well anti-wax.

[0066] The slow-release anti-wax microcapsule inorganic framework 3 proppant is composed of the following raw materials in parts by weight: zinc sulfate: sodium silicate: sodium carbonate = 2:3:5;

[0067] The macromolecule wrapping film compounded on the outer layer of the sustained-release microc...

Embodiment 3

[0071] A slow-release microcapsule used for oil well anti-scaling, anti-wax or viscosity reduction is filled with a cross-mixed structure composed of an inorganic skeleton 3 and a pharmaceutical component 4 in a polymer composite film 2 with a surface mesh 1 things.

[0072] The volume and shape of the present invention are solid cylindrical particles with a diameter of 8 mm and a height of 12 mm. The addition of the inorganic skeleton 3 can maintain the shape, so that the density of the pharmaceutical component 4 is 1.4 g / cm3.

[0073] A slow-release microcapsule for oil well anti-scaling, anti-wax or viscosity-reducing is used as a slow-release microcapsule for oil well anti-wax and anti-scaling purposes.

[0074] The slow-release anti-wax and anti-scaling microcapsule inorganic framework 3 proppant is composed of the following raw materials in parts by weight: zinc sulfate: sodium silicate: sodium carbonate = 2:3:5;

[0075] The polymer wrapping film compounded on the oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com