Honeycomb sandwich composite material with high-speed impact resistance and wave-absorbing stealth functions and preparation method of honeycomb sandwich composite material

A high-speed impact, composite material technology, used in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of difficult to control the thickness of the coating, limited impact resistance, and difficulty in ensuring uniformity. The effect of improving electromagnetic wave absorption performance, improving impact resistance performance, and strong electromagnetic wave loss ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

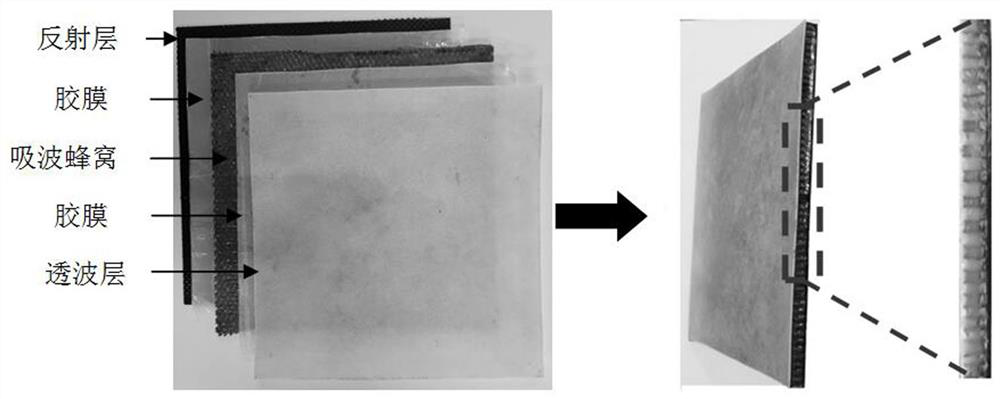

[0049] The present invention further provides a preparation method of a honeycomb sandwich composite material with both high-speed impact resistance and wave-absorbing stealth functions, comprising the following steps:

[0050] (1) mixing shear thickening glue and wave absorbing functional particles to obtain wave absorbing functional particles / shear thickening glue;

[0051] (2) Put pure shear-thickening glue or wave-absorbing functional particles / shear-thickening glue into the mould respectively, and press into the required shape and thickness;

[0052] (3) Put the pure shear thickening glue with the desired shape and thickness obtained in step (2) into the mold, then put it into the honeycomb, and press the pure shear thickening glue into the honeycomb under a certain pressure to obtain Honeycomb filled with a certain high degree of pure shear thickening glue;

[0053] (4) Put the wave-absorbing functional particles / shear-thickening glue with the desired shape and thicknes...

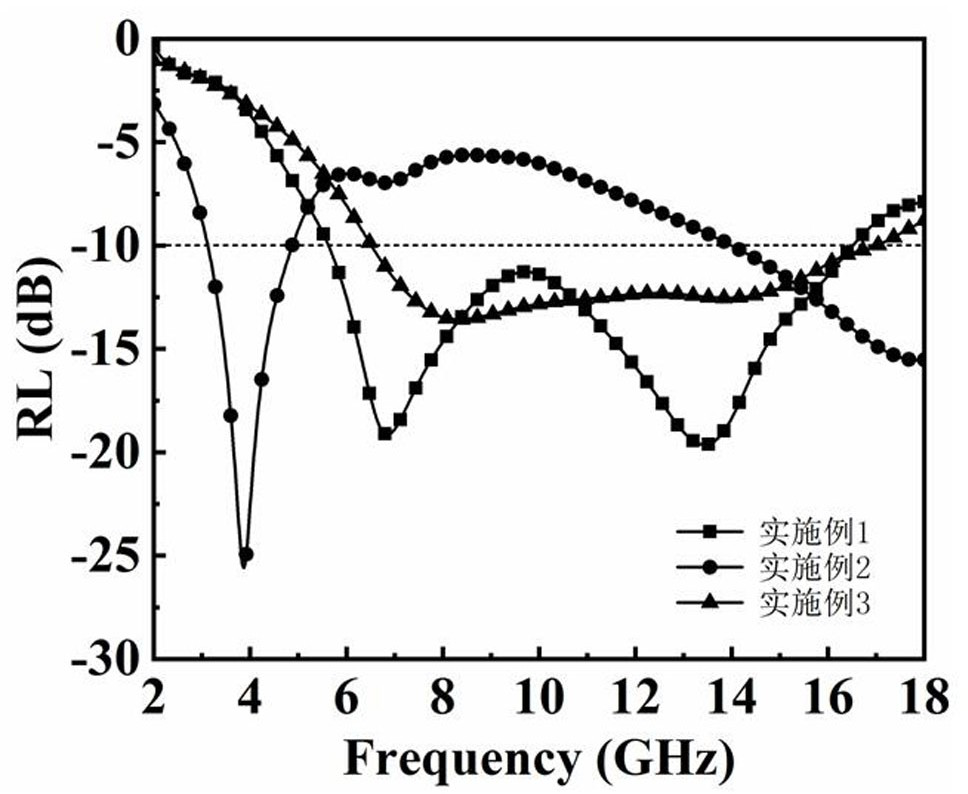

Embodiment 1

[0069] (6) Weigh the pure shear thickening glue and put it into the mold, press it into a square of 180×180mm under the pressure of 1MPa, and then put the 180×180×5mm honeycomb into the mold, under the pressure of 1MPa, put the pure The shear thickening glue is pressed into the honeycomb, so that the thickness of the pure shear thickening glue in the honeycomb is 3.5mm.

[0070] (7) Weigh the flaky carbonyl iron / shear-thickening glue and put it into a mold, press it into a square of 180×180mm under a pressure of 1MPa, and then press the side obtained in step (6) into a pure shear-thickener The honeycomb of the thick glue is put into the mold and the side that is not pressed into the shear thickening glue is brought into contact with the flaky carbonyl iron / shear thickening glue. into the honeycomb, so that the thickness of the sheet carbonyl iron / shear thickening glue in the honeycomb is 1.5mm to obtain a wave absorbing layer.

[0071] (8) Place the wave-transmitting layer, w...

Embodiment 2

[0073] (6) Weigh the pure shear thickening glue and put it into the mold, press it into a square of 180×180mm under the pressure of 1MPa, and then put the 180×180×5mm honeycomb into the mold, under the pressure of 1MPa, put the pure The shear thickening glue is pressed into the honeycomb, so that the thickness of the pure shear thickening glue in the honeycomb is 2mm.

[0074] (7) Weigh the flaky carbonyl iron / shear-thickening glue and put it into a mold, press it into a square of 180×180mm under a pressure of 1MPa, and then press the side obtained in step (6) into a pure shear-thickener The honeycomb of the thick glue is put into the mold and the side that is not pressed into the shear thickening glue is brought into contact with the flaky carbonyl iron / shear thickening glue. into the honeycomb, so that the thickness of the sheet carbonyl iron / shear thickening glue in the honeycomb is 3 mm to obtain a wave absorbing layer.

[0075] (8) Place the wave-transmitting layer, wave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com