Extrusion shearing mould and forming method capable of achieving magnesium alloy grain refinement

A technology of grain refinement and magnesium alloy, which is applied in the field of extrusion shearing die and forming, can solve the problems of high extrusion force of equipment, die structure and strength, etc., and achieve simple forming method, simple structure, and improved mechanical strength. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

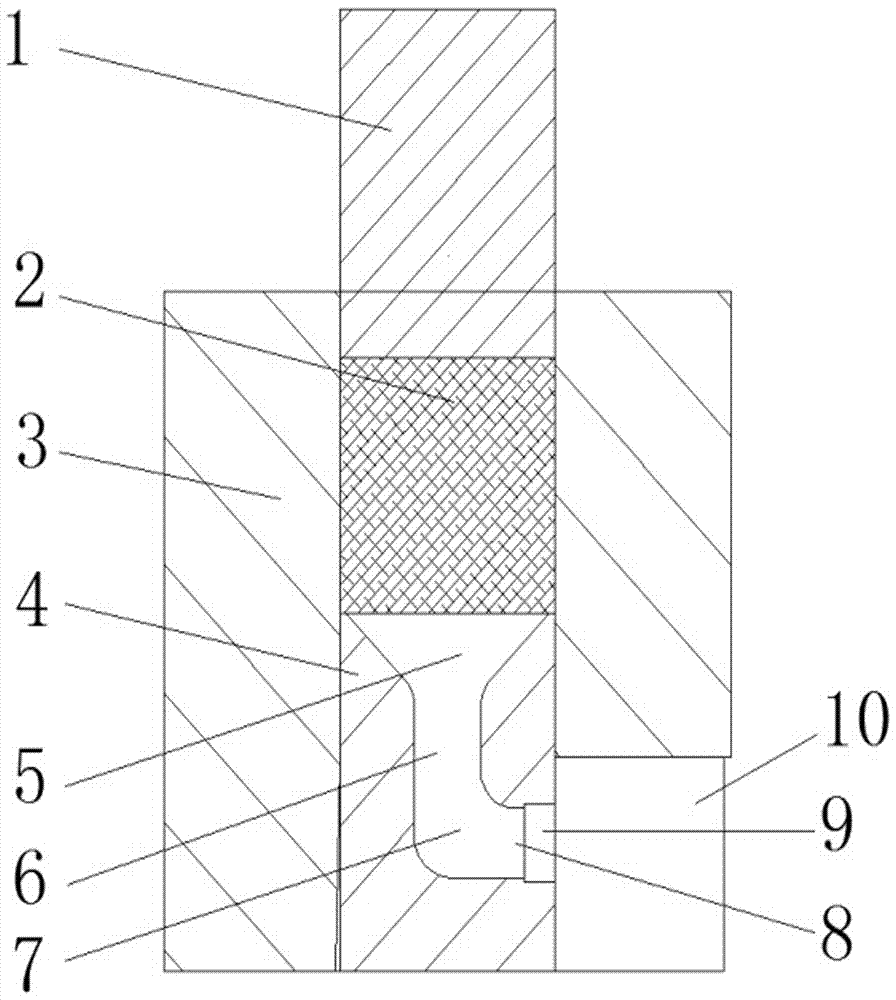

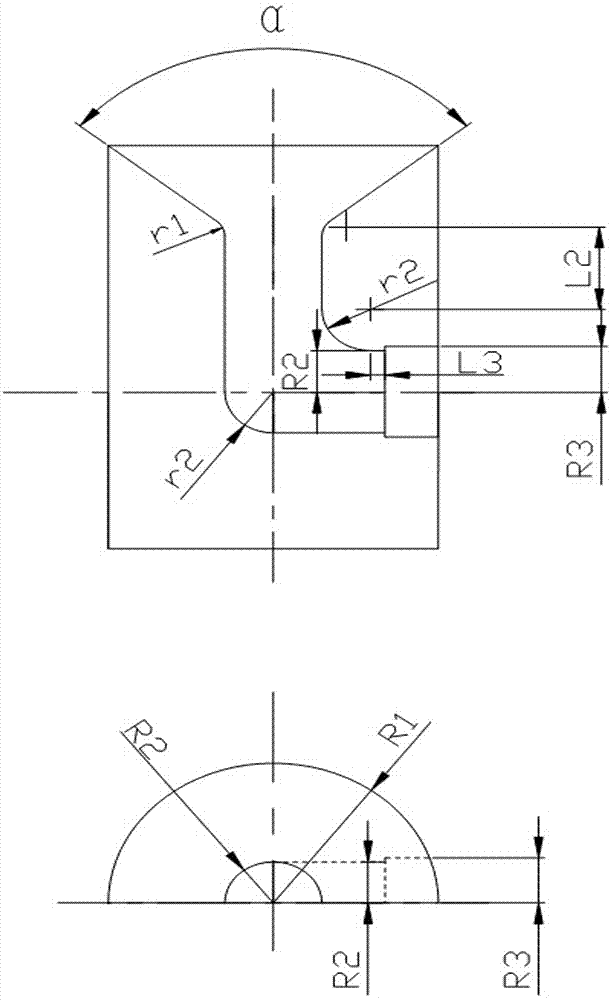

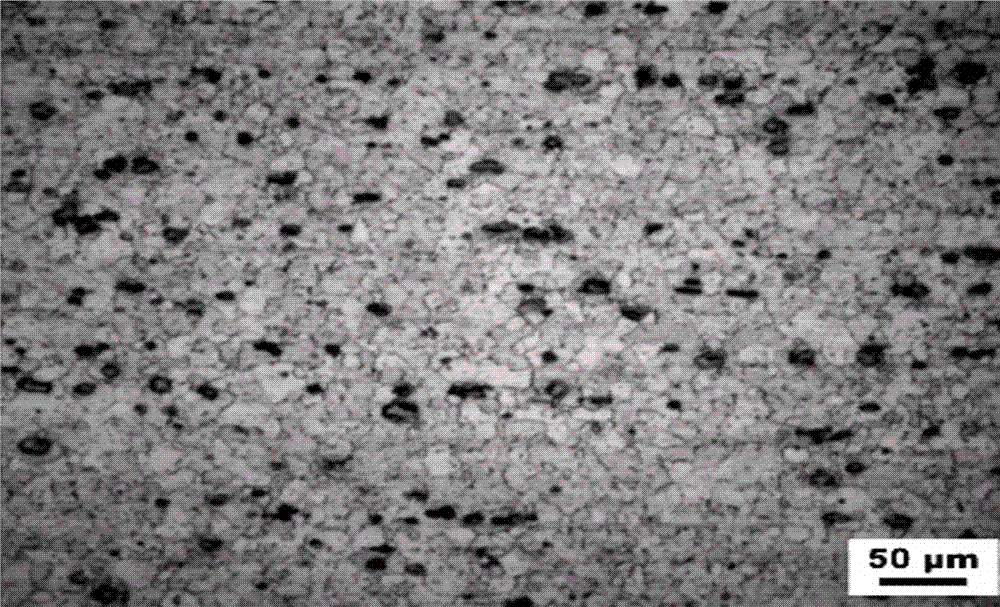

[0042] The material is Mg-6Zn-0.5Cu-0.6Zr alloy, and the extrusion ratio is set to 12. Firstly, the cylindrical billet with a radius of 17.4 mm is heated to 400° C. and kept for 10 hours for homogenization treatment. Then assemble the sleeve and the extruded shear insert together, and preheat to 400°C; preheat the compact to 200°C. Heat the homogenized billet to 400°C again, keep it warm for 2 hours, place it on the top of the extrusion shearing insert in the sleeve, put a briquetting block on the upper end of the billet for extrusion, and the extrusion speed is 2.5m / min, and the bar is air-cooled at the outer end of the hollow slot of the sleeve. Before extrusion, apply high-temperature lubricant MoS on the inner surface of the sleeve, the surface of the compact and the billet, and the inner and outer surfaces of the extrusion shear insert 2 . After the extrusion is finished, the sleeve is cushioned, and the ejector rod is placed above the pressing block to push out the p...

Embodiment 2

[0045] The material is Mg-4Zn-1Y-0.5Zr alloy, and the extrusion ratio is 40. First, the cylindrical billet with a radius of 94.5 mm is heated to 450° C. and kept for 15 hours for homogenization. Then assemble the sleeve and the extrusion shear insert together, and preheat to 450°C; preheat the compact to 250°C. Heat the homogenized billet to 450°C again, keep it warm for 2 hours, place it on the top of the extrusion shearing insert in the sleeve, put a briquetting block on the upper end of the billet for extrusion, and the extrusion speed is 1.5m / min, and the bar is air-cooled at the outer end of the hollow slot of the sleeve. Before extrusion, apply high-temperature lubricant MoS on the inner surface of the sleeve, the surface of the compact and the billet, and the inner and outer surfaces of the extrusion shear insert 2 . After the extrusion is finished, the sleeve is cushioned, and the ejector rod is placed above the pressing block to push out the pressing block, extrus...

Embodiment 3

[0048] The material is Mg-6Zn-0.5Zr alloy, and the extrusion ratio is 25. Firstly, the cylindrical billet with a radius of 49.5 mm is heated to 350° C. and kept for 20 hours for homogenization. Then assemble the sleeve and the extrusion shear insert together, and preheat to 350°C; preheat the compact to 220°C. Heat the homogenized billet to 350°C again, keep it warm for 2 hours, place it above the extrusion shearing insert in the sleeve, put a briquetting block on the upper end of the billet for extrusion, and the extrusion speed is 2m / min, and the bar is air-cooled at the outer end of the hollow slot of the sleeve. Before extrusion, apply high-temperature lubricant MoS on the inner surface of the sleeve, the surface of the compact and the billet, and the inner and outer surfaces of the extrusion shear insert 2 . After the extrusion is finished, the sleeve is cushioned, and the ejector rod is placed above the pressing block to push out the pressing block, extrusion shearin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com