Separation type mild steel shock absorber

A shock-absorbing tenon and separate technology, applied in the field of shock-absorbing tenons, can solve problems such as difficulty in satisfying the dynamic performance of railway bridges, small initial stiffness of shock-absorbing and isolation design, and increased seismic response of bridge piers, achieving good shock-absorbing and isolation effects, Good shock absorption effect, the effect of shock absorption limiting horizontal displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below according to the embodiments shown in the accompanying drawings. It can be thought that embodiment disclosed this time is an illustration in every point, and is not restrictive. The scope of the present invention is not limited by the description of the following embodiments but only by the scope of the claims, and includes the same meaning as the scope of the claims and all modifications within the scope of the claims.

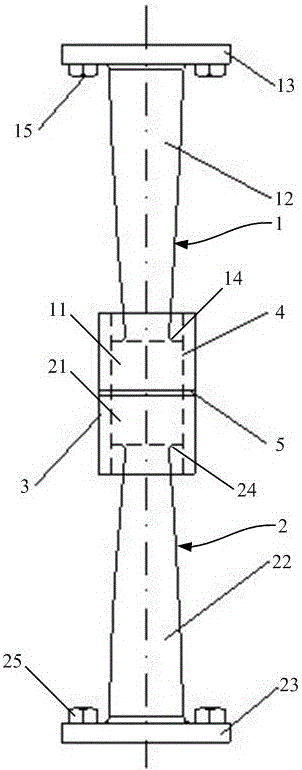

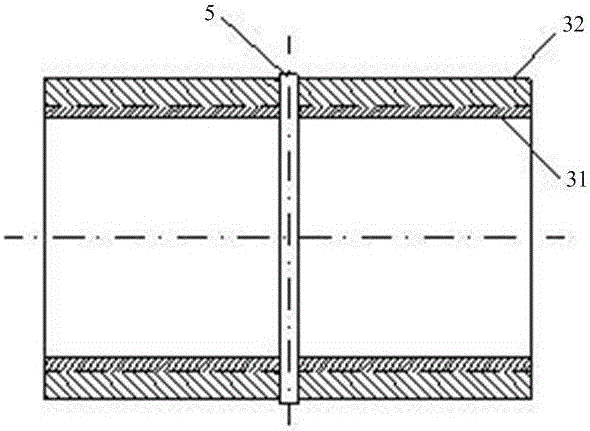

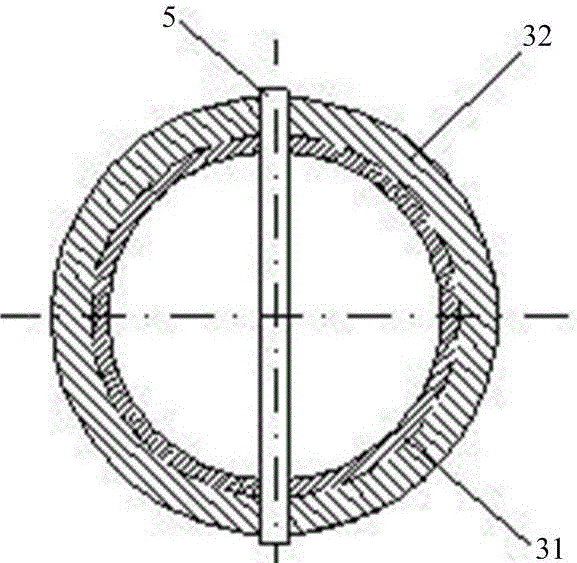

[0019] The separated mild steel shock-absorbing tenon of the present invention is a mild steel yielder mainly for bending deformation, has high initial rigidity and plastic deformation capacity, and is suitable for shock-absorbing and isolating design of medium and small-span railway bridges. The separated mild steel shock-absorbing tenon of the present invention is based on the design concept of separation of support functions, and is used in conjunction with the bridge support. In normal use, the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com