Method for processing three-dimensional curved surface metal plate like piece

A three-dimensional curved surface and metal plate technology, applied in the field of machining, can solve the problems of high cost and inability to process plate deformation, and achieve the effects of large bending deformation, reducing loading force and reducing residual stress.

Inactive Publication Date: 2008-10-22

丁桦

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the thickness of the processed workpiece is large and has a large number of bending and torsion structures, it is necessary to apply a large load to the upper and lower basic groups. The rigidity, strength and forming pressure of the loading structure and the loading structure have high requirements, so the cost is high, and this method cannot process the deformation of the plate with a large thickness relative to the length and width

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

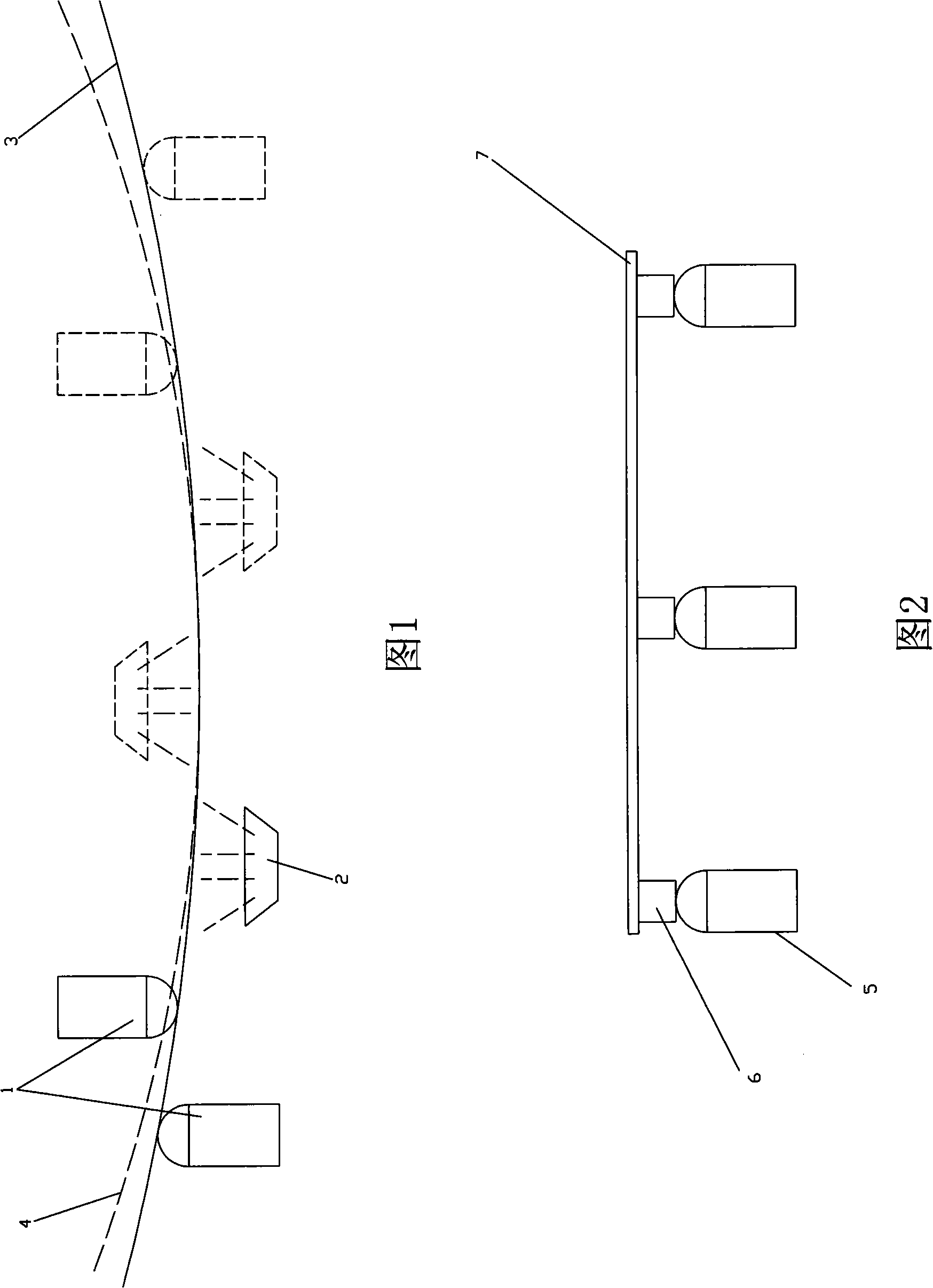

Login to View More Abstract

The invention discloses a method for processing three-dimensional curve metal plates, which is characterized in that according to the forming requirement of the plate, a type that multi-point forming and movable thermal source line heating forming are combined with each other is used for processing the metal plates; by once or a plurality of times of processing disposal, the required three-dimensional curve shape is finally achieved. The method of the invention adopts a method that the multi-point forming method and the movable thermal source line heating forming method are combined with each other; the two methods assist each other, so as to improve the processing precision, reduce the force loaded in the subsequent multi-point forming process, the cost and the times of repeated heating in the movable thermal source line heating forming, and is beneficial to reducing the stress in the plate after the plate is formed as well as ensure the stability of the plate shape after forming.

Description

A method for processing three-dimensional curved metal plate parts technical field The invention relates to the field of mechanical processing, in particular to a method for processing three-dimensional curved metal plate parts. Background technique At present, there are usually two processing methods for the processing of metal plate parts. One is the heating and forming method of the moving heat source line, which uses the local thermoelastic shrinkage deformation of the metal plate after it is partially exposed to high temperature and cooled (natural cooling or water cooling). A forming process that achieves overall bending. This method is more efficient when processing plate-shaped components with small curvature. When the required component has a large curvature or a thick plate, it cannot be processed and formed at one time, and it is necessary to repeat heating at the position of the original heating line. Too many times will lead to a decline in the mechanical pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D11/00G05B19/18

Inventor 丁桦王晓铮聂雪媛丁柱

Owner 丁桦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com