Tube connection device

A technology for pipe joints and pipeline connections, applied in the direction of pipes/pipe joints/pipes, fuel injection devices, threaded connections, etc., which can solve problems such as insufficient compression, damage, and large stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

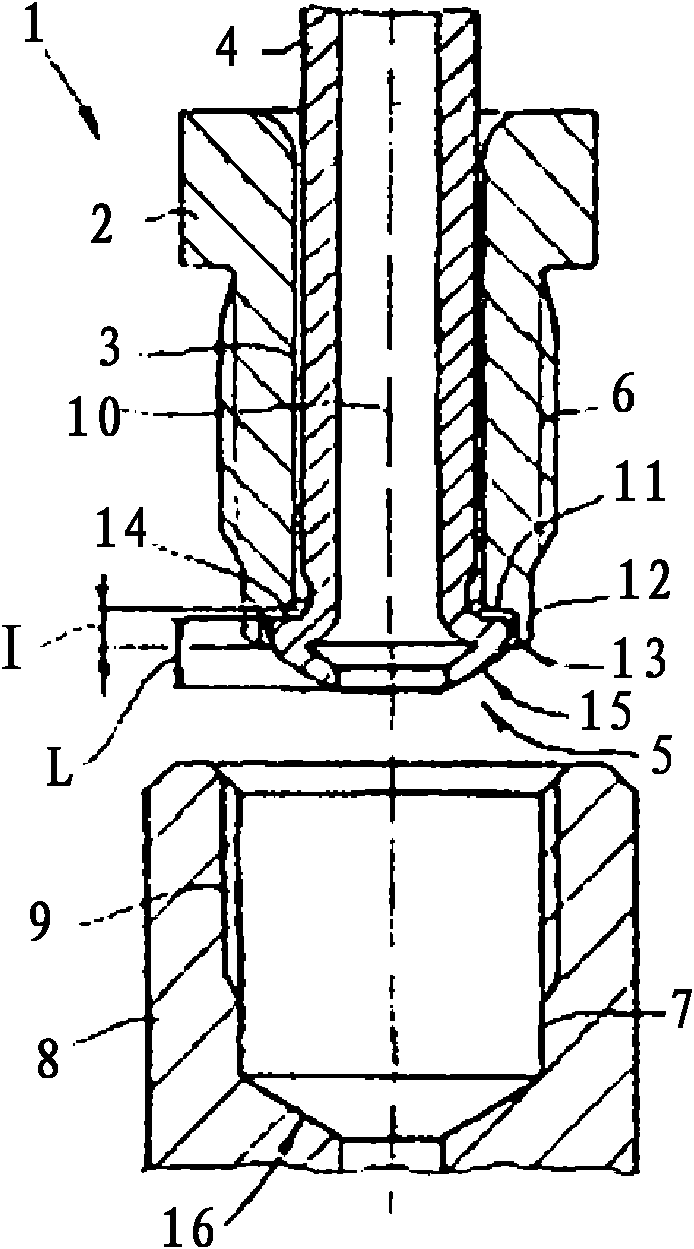

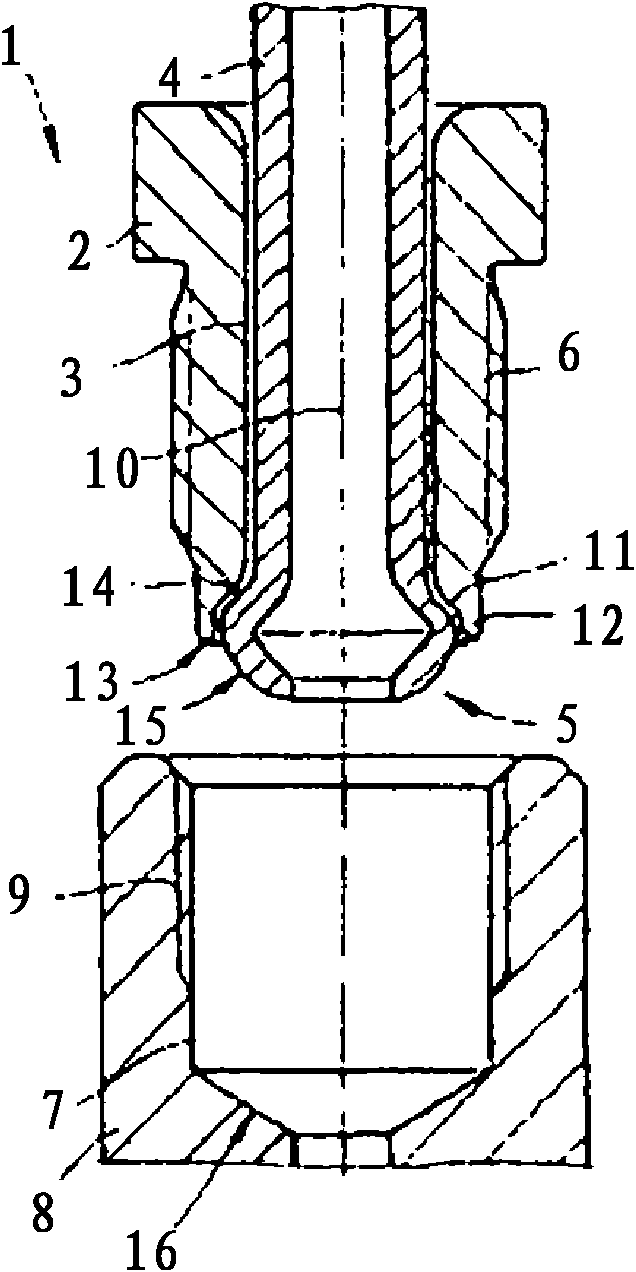

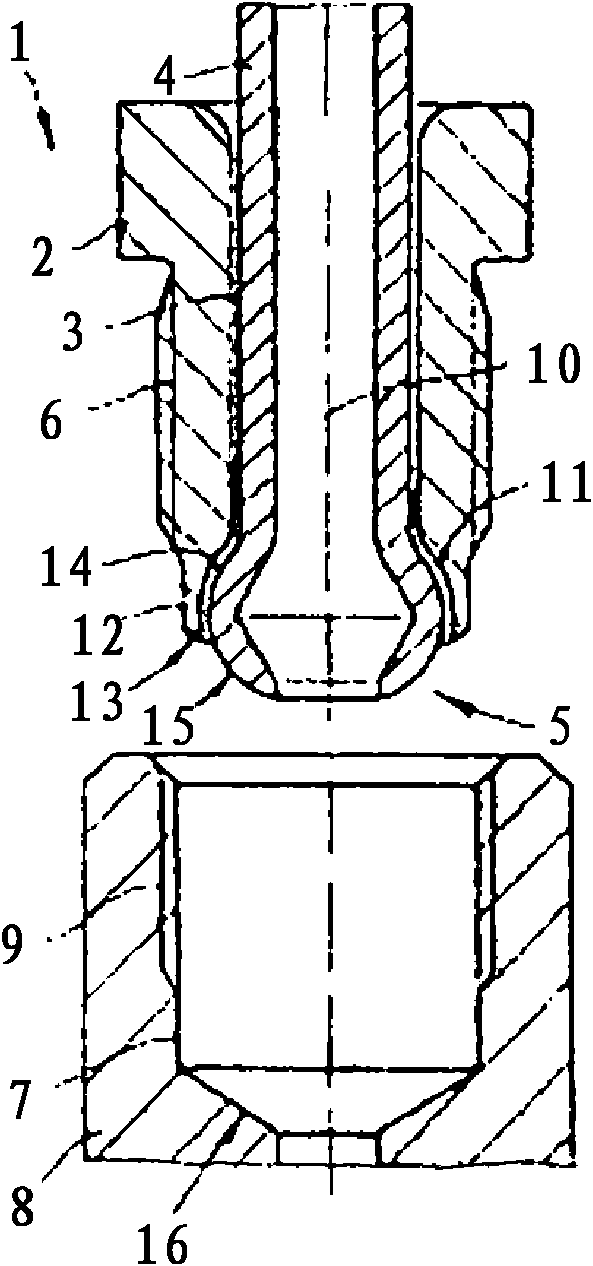

[0037] FIGS. 1 a to 1 c show a pipe connection device 1 with a connection fitting 2 having a receiving channel 3 for a line 4 . In the exemplary embodiment according to FIGS. 1 a to 1 c a line 4 with a flange 5 is arranged in the receiving channel 3 . The connecting fitting 2 here has an external thread 6 which is screwed into a bore 7 of the connecting element 8 with an internal thread 9 . As a result of this screwing in, the connection fitting 2 is moved in the axial direction of the line 4 or the receiving channel 3 or along their longitudinal axis 10 .

[0038] According to the exemplary embodiment shown in FIGS. 1a to 1c, the connection fitting 2 has a front pressing surface 11 from which an annular stop element 12 protrudes and which is formed by the front pressing surface 11. The ring stop element 12 surrounds it. According to FIGS. 1 a to 1 c , the annular stop element 12 has a front contact surface 13 which is of conical configuration. 1a to 1c, it can be seen that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com