Beta titanium alloy composition and preparation method thereof

A β-titanium alloy and composition technology, which is applied in the field of β-titanium alloy composition and its preparation, can solve the problems of difficulty in obtaining equiaxed grains, low elastic modulus, and reduced plasticity, and achieve broad biomedical prospects and plastic shape The effect of large variables and simple mold equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

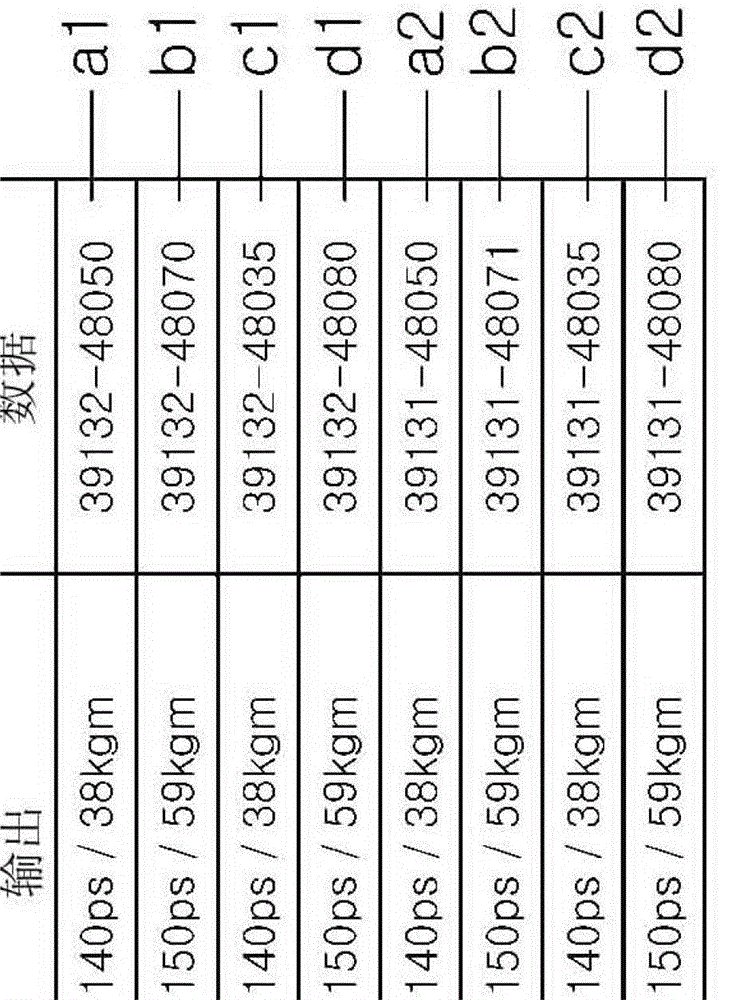

[0038] This embodiment relates to a kind of β titanium alloy composition, and its each component and percentage content are shown in Table 1:

[0039] This embodiment also relates to a method for preparing a β titanium alloy composition, the method comprising the steps of:

[0040] Step 1, take the ingredients and their percentages shown in Table 1. Ti is added in the form of sponge titanium (purity 99.5wt%), Zr is added in the form of sponge zirconium (purity 99.8wt%), and Nb is added in the form of niobium Add in the form of slabs (purity 99.6wt%), Ta in the form of tantalum strips (purity 99.6wt%), and press them into electrodes after thorough mixing;

[0041] Step 2, the electrode is smelted three times in a vacuum consumable electric arc furnace to obtain an ingot;

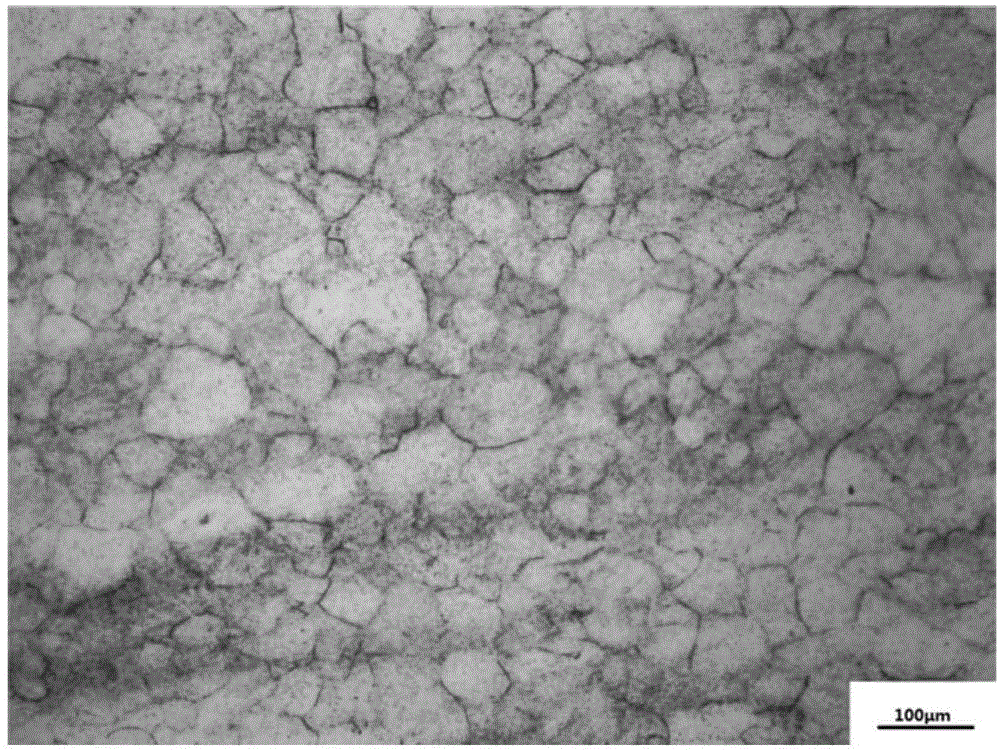

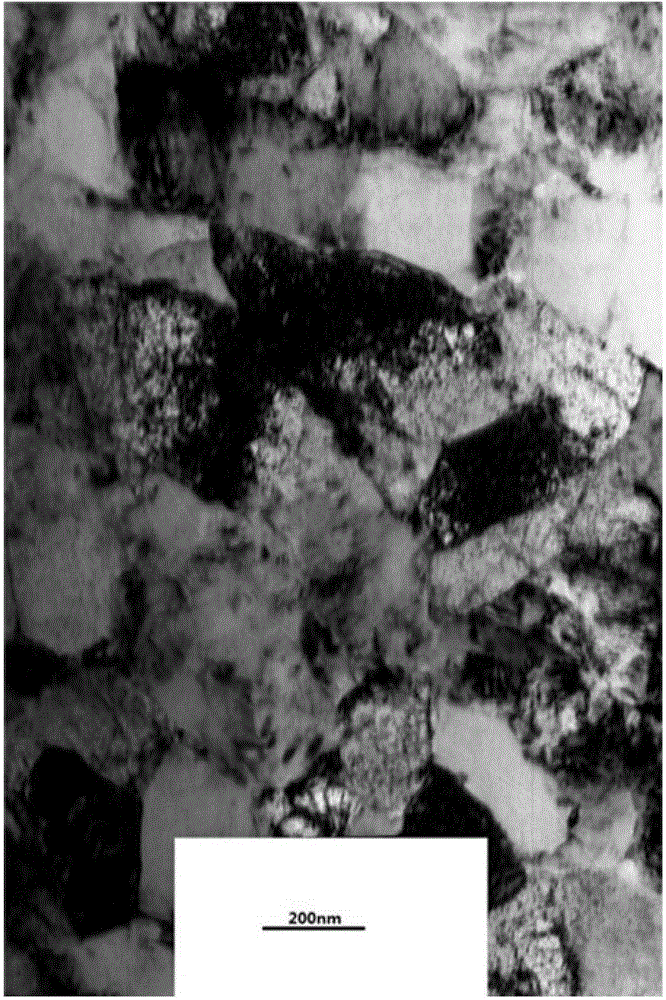

[0042] Step 3: The ingot is forged at 980°C, and the size after forging is Φ40×160mm 3 , and then solution treated at 800°C for 30 minutes and air cooled, seefigure 1 As shown, the crude β titanium alloy co...

Embodiment 2

[0053] This embodiment relates to a kind of β titanium alloy composition, and its each component and percentage content are shown in Table 3:

[0054] This embodiment also relates to a method for preparing a β titanium alloy composition, the method comprising the steps of:

[0055] Step 1: Take the ingredients and their percentages shown in Table 3. Ti is added in the form of sponge titanium (purity 99.5wt%), Zr is added in the form of sponge zirconium (purity 99.8wt%), and Nb is added in the form of niobium Add in the form of slabs (purity 99.6wt%), Ta in the form of tantalum strips (purity 99.6wt%), and press them into electrodes after thorough mixing;

[0056] Step 2, the electrode is smelted three times in a vacuum consumable electric arc furnace to obtain an ingot;

[0057] Step 3: The ingot is forged at 960°C, and the size after forging is Φ40×170mm 3 , and then after solution treatment at 800°C for 40 minutes and air cooling, see figure 1 As shown, the crude β titani...

Embodiment 3

[0069] This embodiment relates to a β titanium alloy composition, and its components and percentages are shown in Table 5:

[0070] This embodiment also relates to a method for preparing a β titanium alloy composition, the method comprising the steps of:

[0071] Step 1, take the ingredients and their percentages shown in Table 5. Ti is added in the form of sponge titanium (purity 99.5wt%), Zr is added in the form of sponge zirconium (purity 99.8wt%), and Nb is added in the form of niobium Add in the form of slabs (purity 99.6wt%), Ta in the form of tantalum strips (purity 99.6wt%), and press them into electrodes after thorough mixing;

[0072] Step 2, the electrode is smelted three times in a vacuum consumable electric arc furnace to obtain an ingot;

[0073] Step 3: The ingot is forged at 980°C, and the size after forging is Φ40×160mm 3 , and then solution treated at 800°C for 30 minutes and air cooled, see figure 1 As shown, the crude β titanium alloy composition is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com