Manufacturing process for high-strength corrosion-resistant aluminum alloy forged piece

A manufacturing process and aluminum alloy technology, which is applied in the production process field of 2A14 high-strength corrosion-resistant aluminum alloy ring forgings, can solve the problems of difficult control of deformation, low material utilization rate, small margin, etc. Corrosion ability, improve anti-corrosion ability, promote full crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: The manufacturing process of a high-strength and heat-resistant 2A14 aluminum alloy forging is as follows:

[0029] (1) Material preparation: Saw the aluminum alloy extruded bar of H112 state (hot-processed state) Φ300 according to the weight of process requirements to 790±5mm, and mark the end face of the billet with a marker pen before forging to distinguish the three directions during forging, get raw materials;

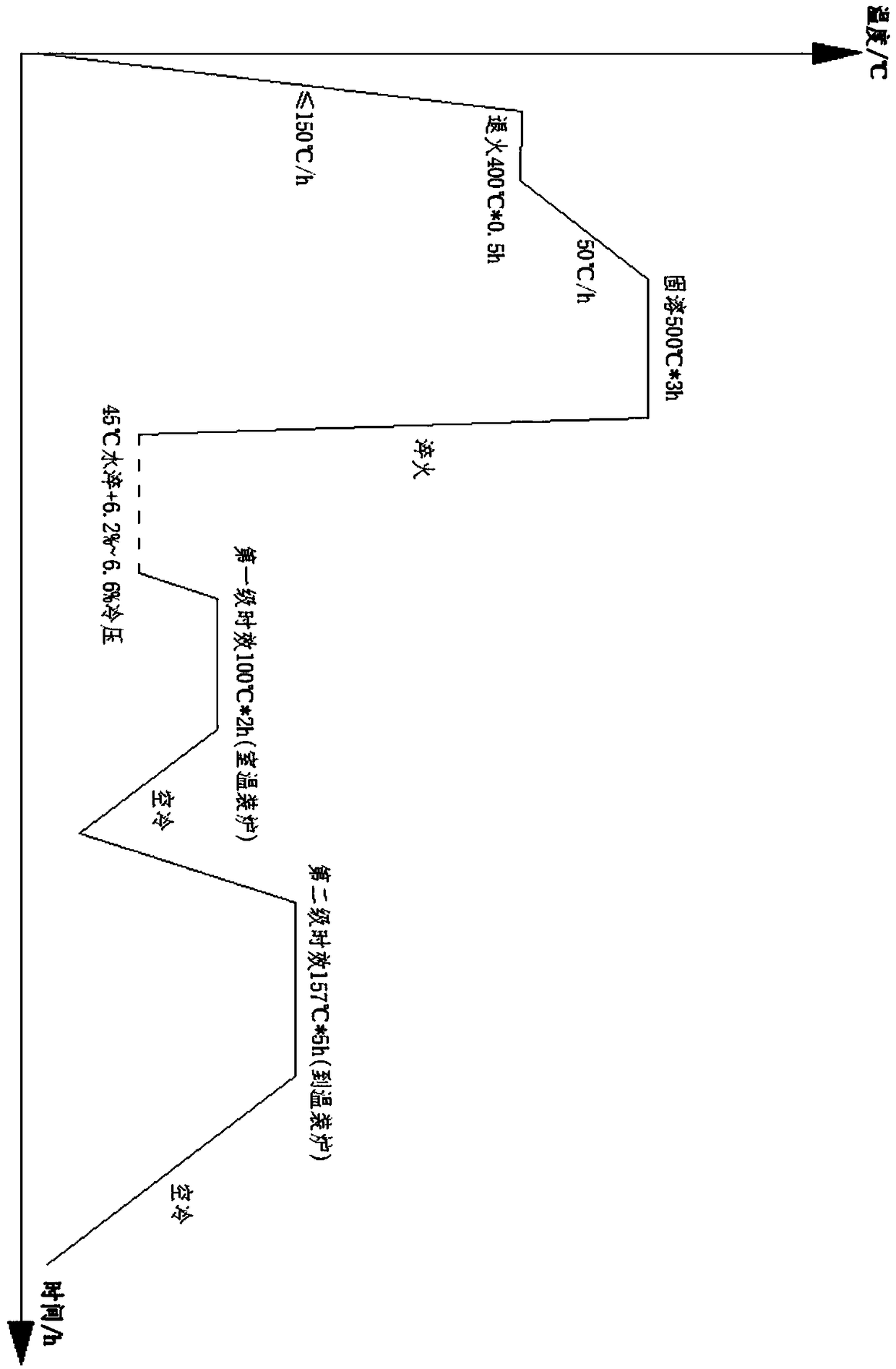

[0030] (2) Heating: Put the raw material obtained in step (1) into a furnace at room temperature, raise the temperature to 400±5°C according to the power (≤150°C / h), and then raise the temperature to 460±5°C at a heating rate of 50°C / h and then keep it warm 6h for heating before forging, and ensure the uniformity of the furnace temperature, to heat the raw materials;

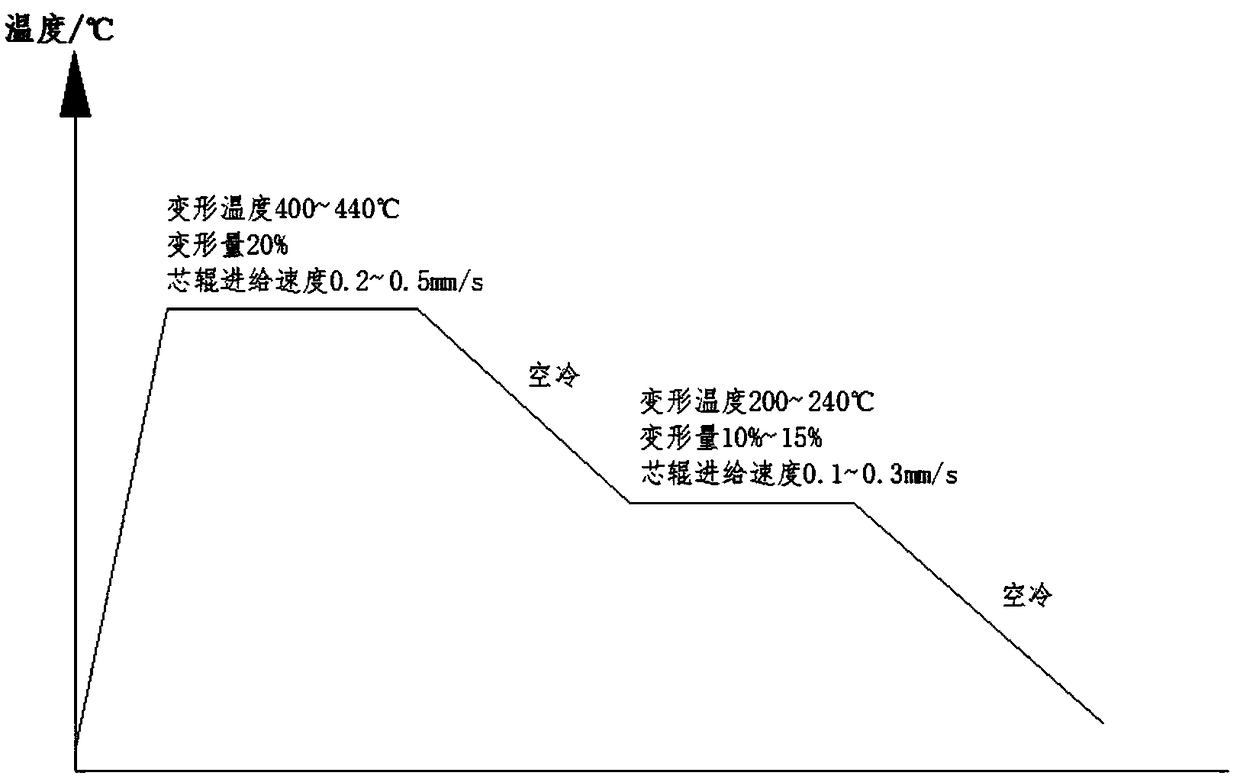

[0031] (3) Multi-axis forging: forging the heated raw materials obtained in step (2), keeping the initial forging temperature at 420-460°C, and the final forging temperature ≥ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com