Site rust-removing and corrosion-preventing method for steel piece of electric power system

A power system and steel technology, applied in the direction of metal material coating process, etc., can solve the problems of easy corrosion and rust, waste, and difficulty in removing rust and anti-corrosion of power equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The preparation of embodiment 1 " four in one " surface treatment liquid

[0064] Formula (components and content per liter of "four-in-one" surface treatment solution):

[0065] h 3 PO 4 (85%) 100ml / L

[0067] Manganese nitrate 2g / L

[0068] NaNO 2 3g / L

[0069] Tartaric acid 20g / L

[0070] OP-10 1.5g / L

[0071] water balance

[0072] Preparation steps:

[0073] Set the volume of the "four-in-one" surface treatment solution to be prepared. Calculate the required amount of each component and the amount of water according to the formula (at this time, the amount of water can be an approximate amount). Get two-thirds of the required water, add the amount of phosphoric acid under stirring, add the amount of zinc powder after mixing, and then add the amount of manganese nitrate and sodium nitrite (NaNO 2 ), tartaric acid, stir to dissolve completely. Dissolve OP-10 (alkylphenol polyoxyethylene ether) in warm water...

Embodiment 2~8

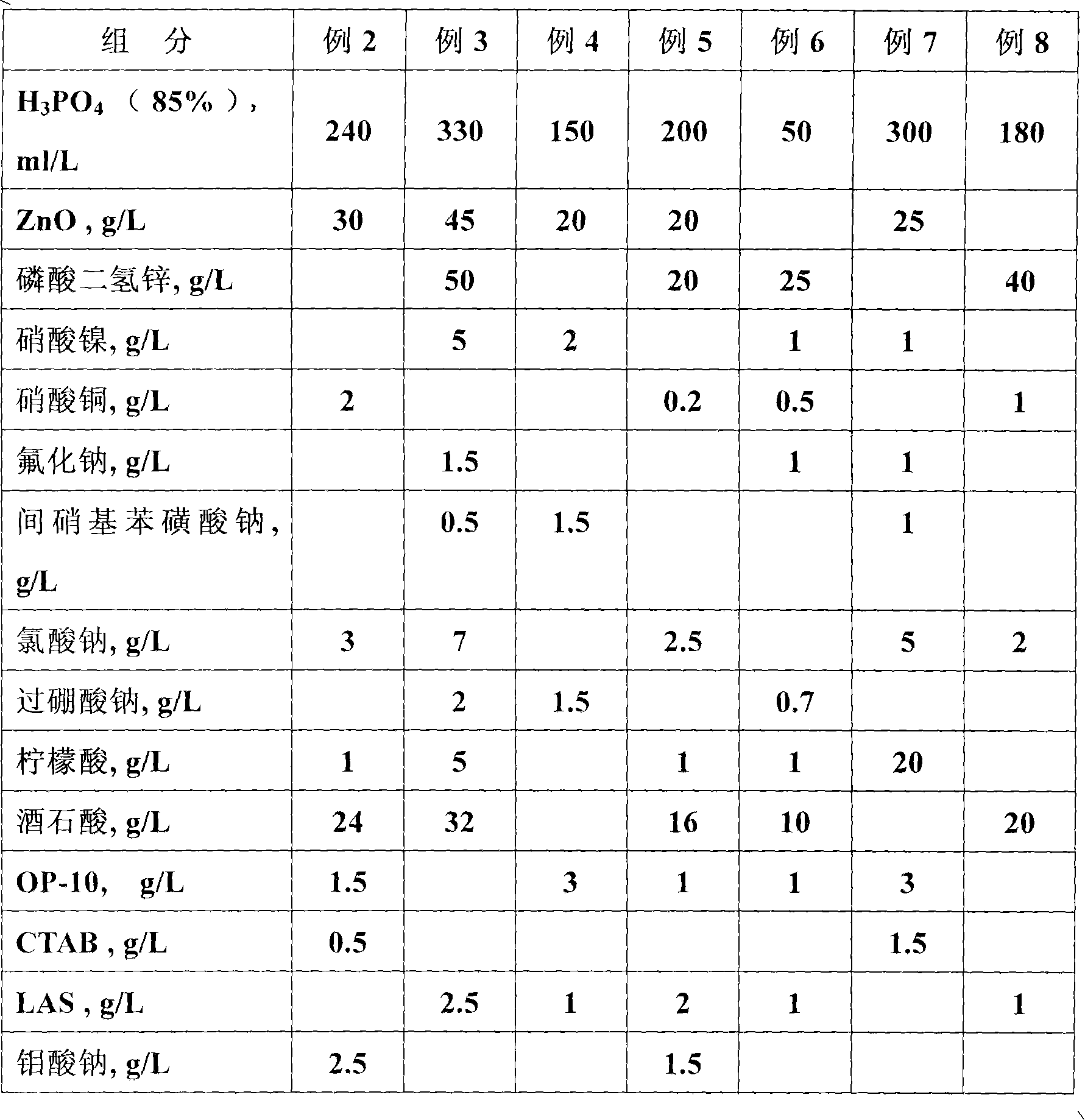

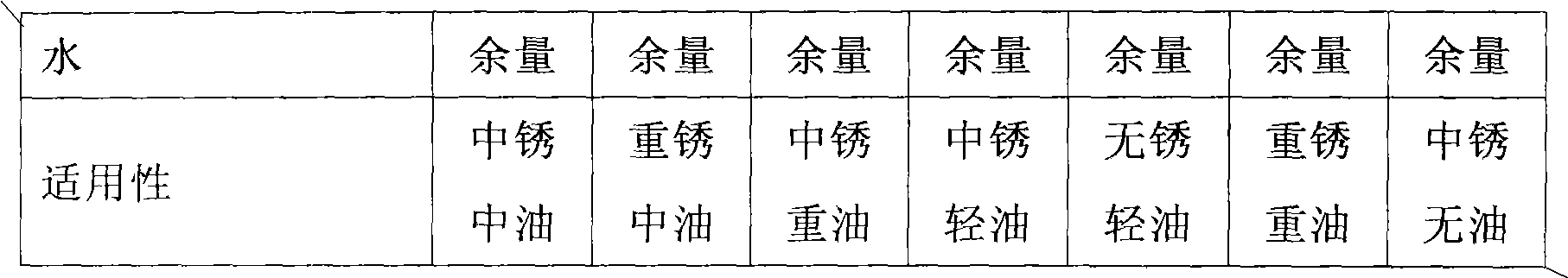

[0076] The formulations for the preparation of the "four-in-one" surface treatment solution in Examples 2-8 are shown in the table below. The preparation method is the same as that of Example 1. Values in the table, H 3 PO 4 (85%) is the number of milliliters per liter of surface treatment liquid, and others are the number of grams per liter of surface treatment liquid.

[0077] "Four in one" surface treatment fluid formula

[0078]

[0079]

[0080]Note: In the table, nickel nitrate, copper nitrate, sodium fluoride, and sodium m-nitrobenzenesulfonate are phosphating reaction accelerators; sodium chlorate and sodium perborate are oxidants; citric acid and tartaric acid are polyhydroxy organic acid complexing agents ; OP-10, CTAB, and LAS are surfactants, wherein OP-10 is a nonionic surfactant, CTAB is a cationic surfactant, and LAS is an anionic surfactant. The zinc content in zinc oxide is 81.38%, and the zinc content in zinc dihydrogen phosphate is 22.14%.

Embodiment 9

[0082] Moderately corroded transformer radiator oil valve bolts with moderate oil stains on the surface. Use a steel wire brush to remove floating rust and dust on the surface of the bolts on site, and then apply the "four-in-one" surface treatment solution prepared in Example 2 to the surface of the bolts. Pay attention to the complete and uniform brushing without any accumulation of liquid. After the phosphating film is completely dry, first apply a layer of epoxy zinc-rich primer, and then apply a layer of high-chlorinated polyethylene anti-corrosion topcoat after the primer is completely dry. There is no need to cut off the power or disassemble the bolts, and the rust removal and anticorrosion treatment of the bolts can be completed online. After one year, the treated bolts have no traces of rust on the surface and have good corrosion resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com