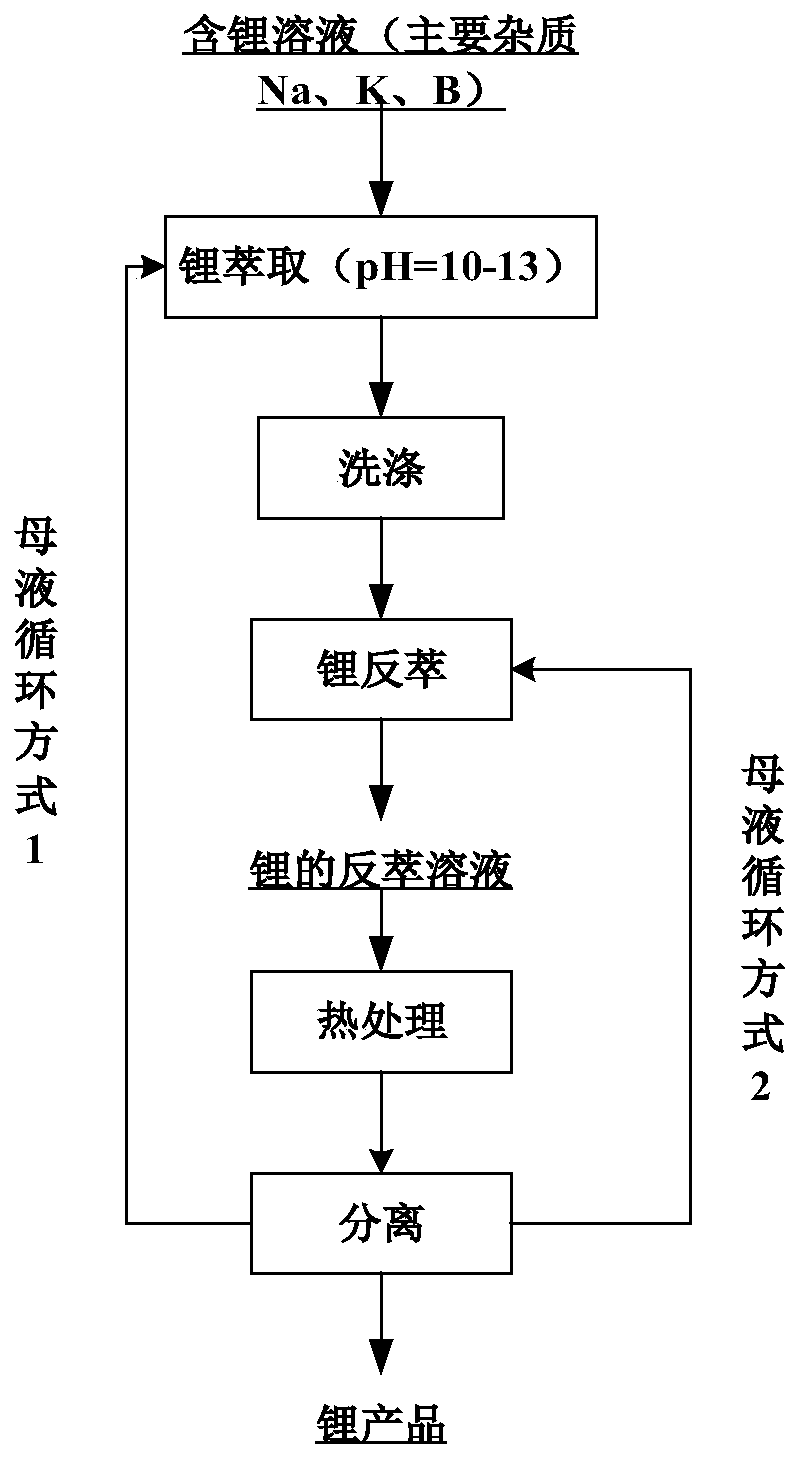

Method for lithium extraction through extraction-reverse extraction, separation and purification

A technology for separation, purification and extraction of lithium, applied in the direction of improving process efficiency, can solve the problems of low lithium yield, large investment, long process flow, etc., and achieve the effects of high preparation cost, reduced operating cost, and reduced environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

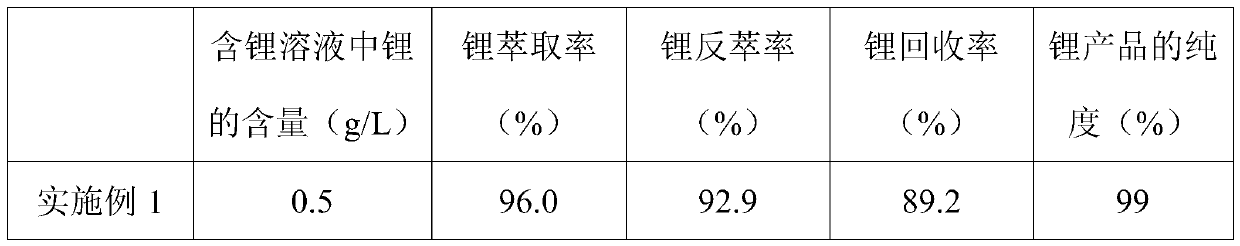

Embodiment 1

[0072] This embodiment provides a method for extracting-back-extracting, separating, purifying and extracting lithium, comprising the following steps:

[0073] (1) TBP and LIX84 are mixed to form a composite extractant, and the volume ratio of TBP and LIX84 is controlled to be 0.2:1, and sulfonated kerosene is used as a diluent, and the volume percentage of the composite extractant is 20%. Dodecyl alcohol is used as a phase modifier, and under the condition of pH=10, it is extracted with the solution obtained by purifying high-valent metal ions from the lithium battery waste leaching solution with a lithium concentration of 0.5g / L and a sodium concentration of 10g / L to control lithium battery waste. The volume ratio of the solution obtained by purifying high-valent metal ions by the leach solution to the organic phase is 2.2:1, and then separated to obtain a loaded organic phase with a lithium concentration of 1 g / L;

[0074] (2) The loaded organic phase that step (1) obtains ...

Embodiment 2

[0077] This embodiment provides a method for extracting-back-extracting, separating, purifying and extracting lithium, comprising the following steps:

[0078] (1) Mix TOPO and LIX860 to form a composite extractant, control the volume ratio of TOPO and LIX860 to 1:1, n-dodecane is the diluent, and the volume percentage of the composite extractant is 25%, under the condition of pH=12 Extract with lithium concentration of 2g / L, sodium concentration of 50g / L, potassium concentration of 25g / L and boron concentration of 10g / L lithium sinking mother liquor, control the volume ratio of lithium sinking mother liquor and organic phase to 1:1, Separation then, obtaining lithium concentration is the loaded organic phase of 2g / L;

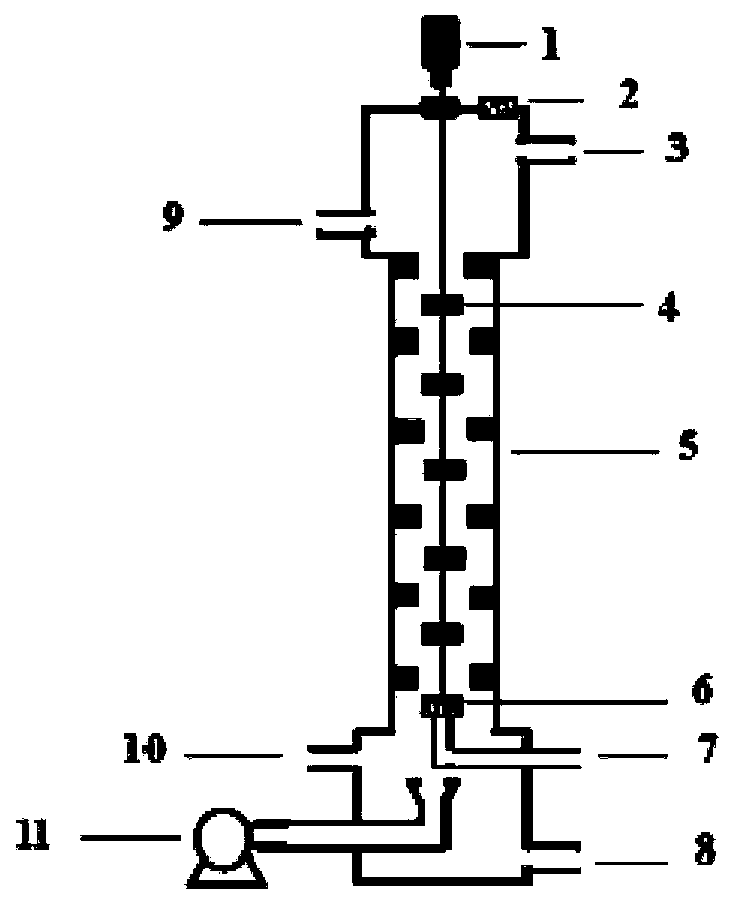

[0079] (2) The loaded organic phase that step (1) obtains is washed 3 times, then carries out gas-liquid-liquid three-phase extraction in continuous countercurrent extraction tower, and the stage number of described extraction tower is 3 grades, uses SO 2 As t...

Embodiment 3

[0082] This embodiment provides a method for extracting-back-extracting, separating, purifying and extracting lithium, comprising the following steps:

[0083] (1) Cyanex923 and LIX54 are mixed to form a composite extractant, the volume ratio of Cyanex923 and LIX54 is controlled to be 2:1, sulfonated kerosene is a diluent, and the volume percentage of the composite extractant is 15%. The concentration of lithium is 5g / L, the concentration of sodium is 100g / L, the concentration of potassium is 50g / L and the concentration of boron is 5g / L salt lake brine concentrated solution is extracted, and the volume ratio of controlling the volume ratio of salt lake brine concentrated solution and organic phase is 0.2:1 , and then separated to obtain a loaded organic phase with a lithium concentration of 2.4g / L;

[0084] (2) The loaded organic phase that step (1) obtains is washed 4 times, then carries out gas-liquid-liquid three-phase extraction in continuous countercurrent extraction towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com