Graphene and carbon nano tube enhanced aluminum matrix composite and preparation method thereof

A technology of carbon nanotubes and reinforced aluminum base, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of formation and other problems, achieve high thermal conductivity, increase preparation cost, and excellent thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

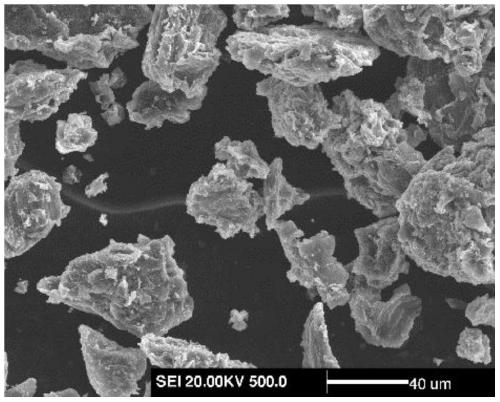

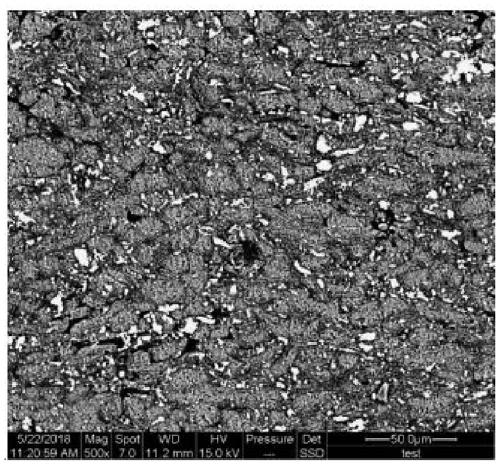

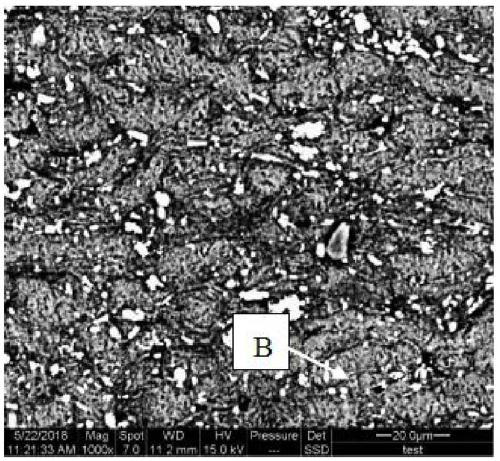

Image

Examples

Embodiment 1

[0049] A graphene and carbon nanotube reinforced aluminum matrix composite material, comprising the following components in mass percentage: 0.1-5.0% composite copper-coated nickel graphene, 0.1-5.0% composite copper-coated nickel carbon nanotube, magnesium powder 5% %, the balance is aluminum powder.

Embodiment 2

[0051] A graphene and carbon nanotube reinforced aluminum matrix composite material, comprising the following components in mass percentage: 0.1-3.0% composite copper-coated nickel graphene, 0.1-3.0% composite copper-coated nickel carbon nanotube, magnesium powder 5% %, the balance is aluminum powder.

Embodiment 3

[0053] A graphene and carbon nanotube reinforced aluminum matrix composite material, comprising the following components in mass percentage: 0.1-1.0% composite copper-coated nickel graphene, 0.1-1.0% composite copper-coated nickel carbon nanotube, magnesium powder 5% %, the balance is aluminum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com