Method for preparing presoma of active electrode material of nano-lithium ion battery and application thereof

An active electrode material, lithium-ion battery technology, applied in battery electrodes, nanotechnology, circuits, etc., can solve the problem of poor electronic conductivity and ion mobility, capacity, rate and cycle life performance, irregular morphology, complex process and other problems, to achieve the effect of excellent electrochemical performance of the product, improved electrochemical performance, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

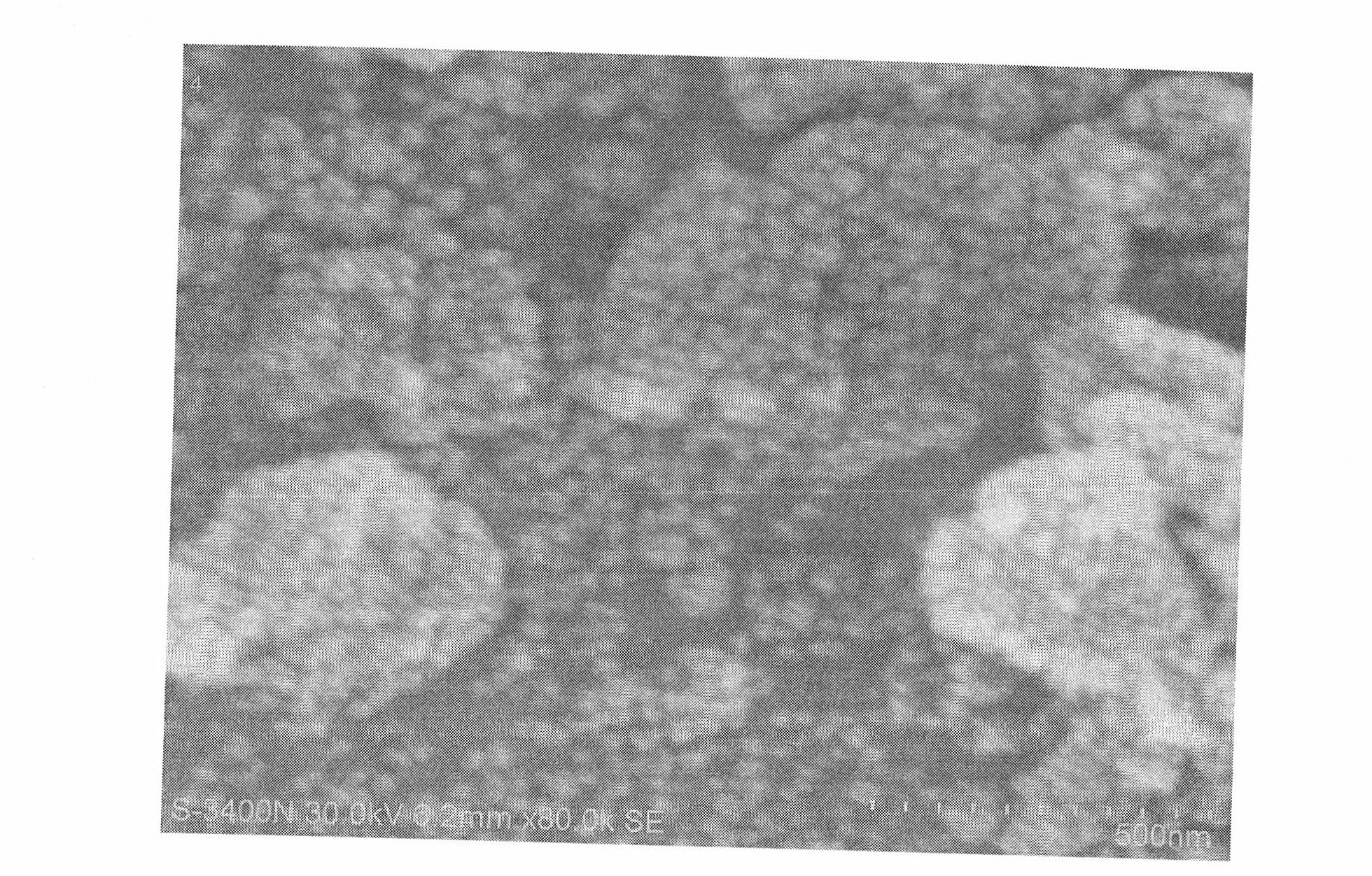

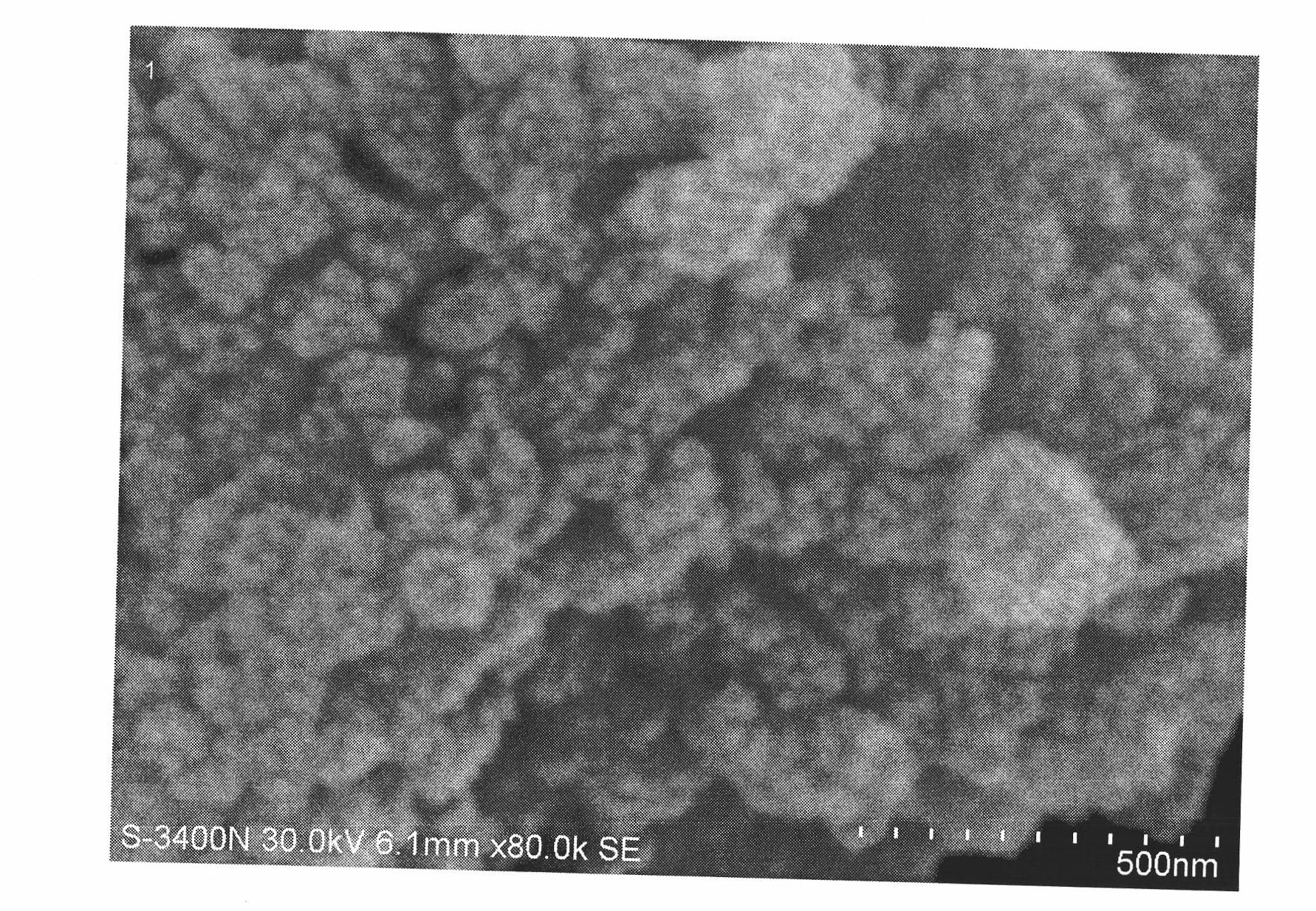

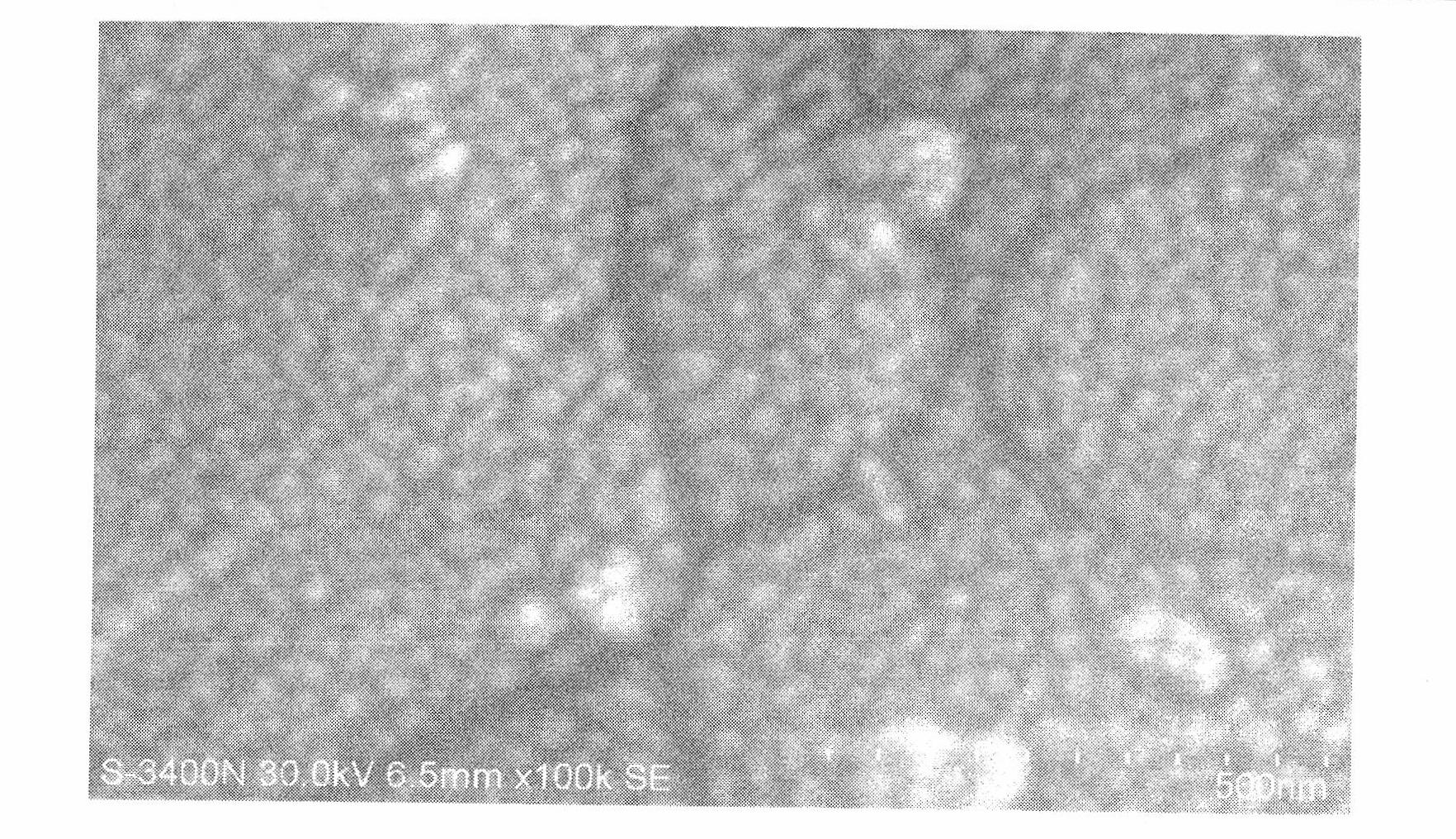

Image

Examples

example 1

[0038] Example 1: The precursor of lithium iron phosphate is prepared from the following raw materials in the following proportions

[0039] initial reactant

weight

4.50 grams

12.00 grams

Cellulose acetate

1.30 grams

cetyltrimethylammonium bromide

0.10 grams

[0040] The specific preparation method is: put the above various raw materials in a container with isopropanol as the solvent and stir evenly, then raise the temperature of the system to 60°C, keep it warm at this temperature, stir and react for one hour, stop heating, and continue stirring for 15 hours Finally, obtain the lithium iron phosphate precursor slurry, dry the precursor slurry for an hour to obtain the lithium iron phosphate precursor dry powder A, place the precursor dry powder A in a tube furnace, and heat it at 350 °C under the protection of nitrogen gas. Calcined at ℃ for 4 hours, and after cooling, the pre-calci...

example 2

[0044] Example 2: According to the preparation method similar to Example 1, the nanometer lithium iron phosphate precursor was obtained by using the raw materials with the following ratio:

[0045] initial reactant

weight

4280 grams

12000 grams

1300 grams

cetyltrimethylammonium bromide

100 g

[0046] The specific steps are as follows: use industrial alcohol as a solvent, uniformly mix the above compounds in a stainless steel reactor with a volume of 100 liters, heat up to 60 ° C, stir for 2 hours under heat preservation conditions, then stop heating, continue to stir for 20 hours, and then naturally Cooling, vacuum drying at 80°C to obtain a lithium iron phosphate precursor A, place this precursor A in an atmosphere furnace, and calcinate at 350°C for 3 hours under the protection of nitrogen gas to obtain a lithium iron phosphate precursor powder, The precursor powder...

example 3

[0048] Example 3: According to the preparation method similar to Example 1, a nanometer lithium iron phosphate precursor was prepared using the raw materials with the following ratio.

[0049] initial reactant

[0050] Stir and mix the above materials with industrial alcohol in a closed container for 0.5 hours, then raise the temperature to 60°C and react for 1 hour, then stop heating and continue stirring for 15 hours to obtain a precursor slurry, and vacuum the precursor slurry at 80°C After drying, the precursor A was obtained, and the precursor A was placed in an atmosphere furnace, and calcined at 350°C for 3 hours under the protection of nitrogen gas to obtain the lithium iron phosphate precursor powder, which was further pulverized with The equipment is crushed and sieved to obtain the precursor B of nano-lithium iron phosphate. The obtained lithium iron phosphate precursor B is placed in a nitrogen atmosphere furnace and calcined at 600° C. for 6 hours, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com