Chemical toughening agent, microcrystalline ceramic material and preparation method thereof and electronic device

A technology of microcrystalline ceramics and tempering agents, applied in the field of chemical tempering agents, microcrystalline ceramic materials and their preparation, can solve problems such as the inability to effectively improve the mechanical properties of microcrystalline ceramic materials, and achieve improved toughness and impact resistance, ion exchange high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

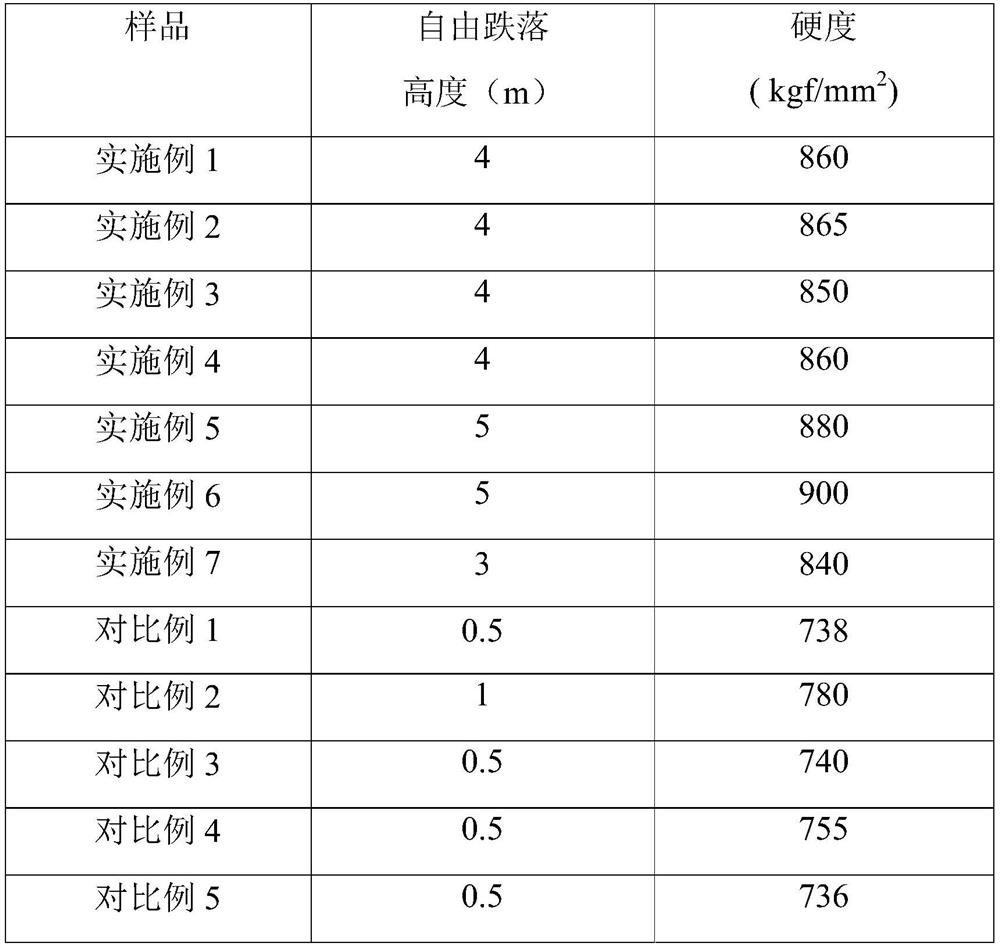

Examples

preparation example Construction

[0051] Further, an embodiment of the present invention provides a method for preparing a microcrystalline ceramic material, including the following step S10.

[0052] Step S10, preheating the microcrystalline ceramic substrate, and then placing it in the chemical toughening agent as described above for tempering to obtain a microcrystalline ceramic material;

[0053] The conditions of tempering treatment are: tempering at 500℃~900℃ for 0.5h~28h.

[0054] In some of the embodiments, the conditions of the above-mentioned preheating step are: heating at 400° C.˜900° C. for 0.5˜5 h.

[0055] In some of these embodiments, the microcrystalline ceramic matrix described above contains an alkali metal oxide. Further, the mass of the alkali metal oxide accounts for 2% to 8% of the mass of the microcrystalline ceramic matrix.

[0056] The above-mentioned alkali metal oxides include, but are not limited to, lithium oxide, sodium oxide, and potassium oxide.

[0057] In some of these emb...

Embodiment 1

[0071] 1) Provide an untempered microcrystalline ceramic matrix, wherein the composition of the microcrystalline ceramic matrix includes lithium oxide, sodium oxide and potassium oxide, the mass percentage of lithium oxide is 5%, the mass percentage of sodium oxide is 1%, and the mass percentage of potassium oxide is 5%. The mass percentage is 1%.

[0072] 2) Preheating the untempered microcrystalline ceramic substrate at 500°C for 1 hour, immersing the preheated microcrystalline ceramic substrate in a chemical toughening agent for the first tempering treatment, tempering at 550 °C for 5 hours, and cooling to room temperature after tempering, The first microcrystalline ceramic was obtained. Wherein, the chemical toughening agent includes sodium nitrate, sodium carbonate, potassium sulfate and auxiliary additives, wherein, the auxiliary additives are diatomaceous earth, and the ratio of moles of sodium nitrate, sodium carbonate, potassium sulfate and auxiliary additives is 9:0....

Embodiment 2

[0076] 1) Provide an untempered microcrystalline ceramic matrix, wherein the composition of the microcrystalline ceramic matrix includes lithium oxide, sodium oxide and potassium oxide, the mass percentage of lithium oxide is 5%, the mass percentage of sodium oxide is 1%, and the mass percentage of potassium oxide is 5%. The mass percentage is 1%.

[0077] 2) Preheat the untempered microcrystalline ceramic substrate at 700°C for 1 hour, immerse the preheated microcrystalline ceramic substrate in a chemical toughening agent for the first tempering treatment, temper it at 750 °C for 5 hours, and cool it to room temperature after tempering. The first microcrystalline ceramic was obtained. The chemical toughening agent includes sodium nitrate, sodium carbonate, potassium sulfate and auxiliary additives, wherein the auxiliary additive is diatomaceous earth, and the molar ratio of sodium nitrate, sodium carbonate, potassium sulfate and auxiliary additives is 2:5:3:0.5 , the melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com