A kind of molecular sieve ion exchange method

A technology of ion exchange and molecular sieve, which is applied in the field of clean and low-cost ion exchange of molecular sieves, can solve the problems of excessive ammonium nitrogen wastewater, complicated operation, low efficiency, etc., and achieve reduced overall energy consumption, high ion exchange efficiency, The effect of reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

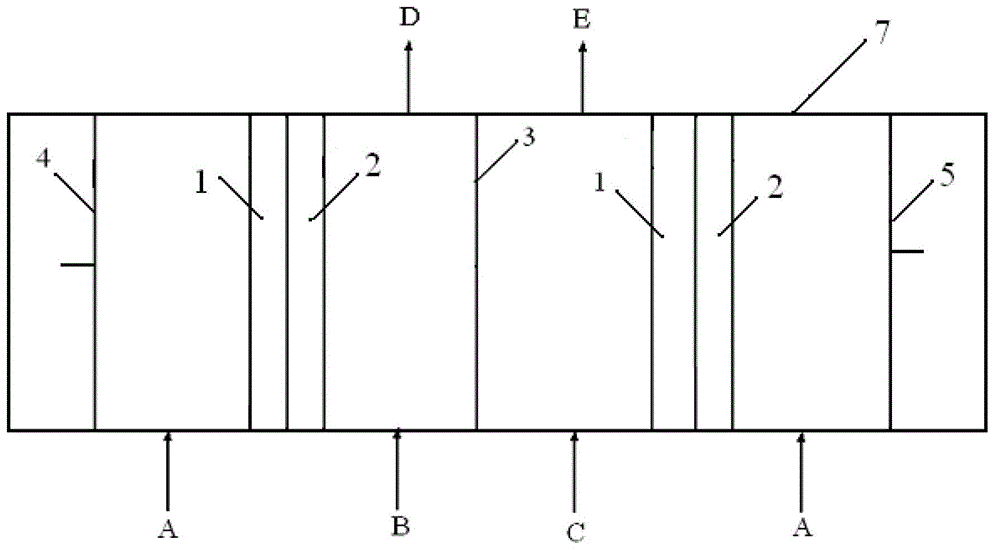

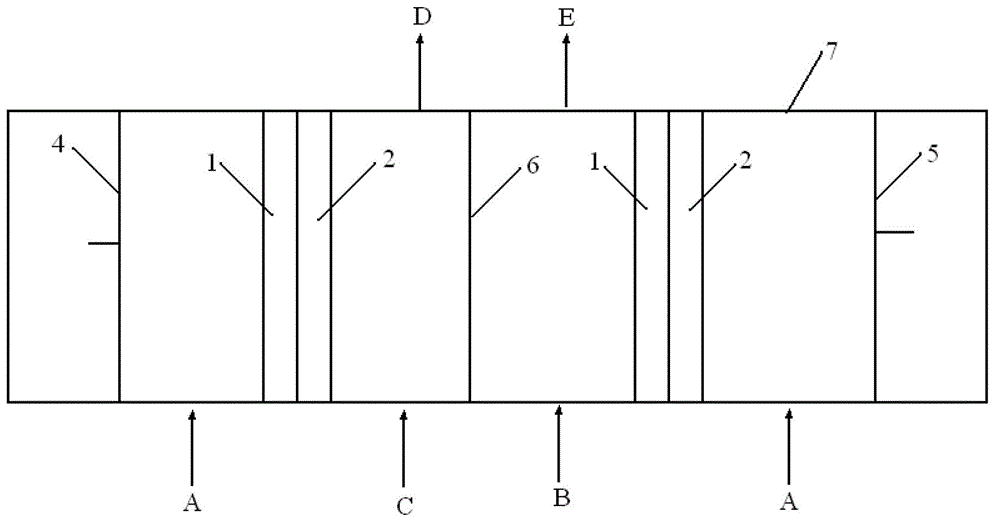

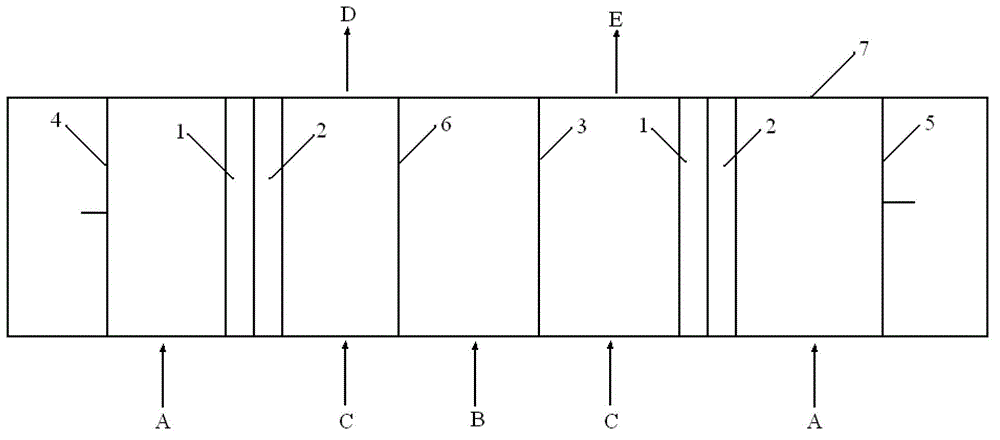

Method used

Image

Examples

Embodiment 1

[0079] (1) Weigh 10kg REUSY molecular sieve (Na 2 The O content is 4.96% by weight, and the relative crystallinity is 58%) is added into 130 kg of deionized water, and stirred evenly to obtain a slurry. The slurry is filtered to obtain a filtrate and a filter cake, and the weight ratio of molecular sieve to water in the filter cake is 1:3.

[0080] (2) Combine the obtained 100kg filtrate with 800g Na 2 SO 4 Mix evenly to obtain an ion-containing aqueous solution, adjust the pH value of the aqueous solution to 12.5 with a concentration of 17% by weight ammonia water, and then carry out solid-liquid separation, and send the obtained liquid phase into the salt chamber storage tank of the bipolar membrane electrodialyzer At the same time, 50kg of deionized water was added to the acid chamber storage tank and the alkali chamber storage tank of the bipolar membrane electrodialyzer at the same time, and 20kg of 2% by weight Na was added to the electrode chamber storage tank. 2 SO ...

Embodiment 2

[0096] (1) Weigh 10kgNaY molecular sieve (NaY 2 The O content is 13.0% by weight, and the relative crystallinity is 85%) is added into 80 kg of deionized water, and stirred evenly to obtain a slurry. The slurry is filtered to obtain a filtrate and a filter cake, wherein the weight ratio of molecular sieve to water in the filter cake is 1:3.

[0097] (2) Combine the obtained 50kg filtrate with 200g Na 2 SO 4 Mix evenly to obtain an ion-containing aqueous solution, adjust the pH value of the aqueous solution to 9 with a concentration of 20% by weight ammonia water, and then carry out solid-liquid separation, and send the obtained liquid phase into the salt chamber storage tank of the bipolar membrane electrodialyzer At the same time, 80kg of deionized water was added to the acid chamber storage tank and the alkali chamber storage tank of the bipolar membrane electrodialyzer at the same time, and 20kg of 3% by weight Na was added to the electrode chamber storage tank. 2 SO 4 ...

Embodiment 3

[0104] (1) Weigh 8kgZSM-5 molecular sieve (Na 2 The O content is 1.2% by weight, and the relative crystallinity is 95%) is added into 100 kg of deionized water, and stirred evenly to obtain a slurry. The slurry is filtered to obtain a filtrate and a filter cake, and the weight ratio of molecular sieve to water in the filter cake is 1:3.

[0105] (2) Combine the obtained 76kg filtrate with 500g Na 2 SO 4 Mix evenly to obtain an ion-containing aqueous solution, adjust the pH value of the aqueous solution to 12 with a concentration of 30% by weight ammonia water, and then carry out solid-liquid separation, and send the obtained liquid phase into the salt chamber storage tank of the bipolar membrane electrodialyzer At the same time, 50kg of deionized water was added to the alkali chamber storage tank and the acid chamber storage tank of the bipolar membrane electrodialyzer at the same time, and 20kg of 3% by weight Na was added to the electrode chamber storage tank. 2 SO 4 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com